Startups and entrepreneurs who are looking for sustainable growth must identify and capitalize on new opportunities in today’s dynamic industry landscape. This comprehensive article dives into five Emerging Manufacturing Sectors and offers in-depth analyses, market forecasts, as well as actionable insights. We explore how new ventures can thrive in high-growth industries, from the emerging field of lithium-ion battery recycling to the innovative production method of lab-grown Diamonds. Each section gives a detailed description of the product and its market dynamics. It also outlines the prospects.

Niir Project Consultancy Services plays a vital role in empowering entrepreneurs through the preparation of detailed techno-economic feasibility reports. These reports, which cover essential aspects like manufacturing processes, raw material, plant layout and financial projections, are extremely valuable. They help entrepreneurs to assess the feasibility of setting up new businesses or industries.

1. Lithium Ion Battery Recycling: A Sustainable Initiative

Product Overview

Modern technology is dominated by lithium-ion (LIB) batteries, which power everything from electronic devices to electric cars (EVs) as well as grid-scale energy-storage systems. While their widespread adoption is crucial for a greener economy, it also presents a major challenge: managing batteries at the end of their lifecycle. LIB recycling is not only an environmentally-friendly practice, but it also offers a significant economic opportunity. These batteries contain valuable material such as nickel, cobalt and manganese.

The recovery of these minerals helps reduce the reliance on virgin mines, minimizes supply chain risk, and lowers the environmental impact associated with battery manufacturing. The process involves collection, dismantling and mechanical treatment (shredding), followed by either hydrometallurgical or pyrometallurgical processes (high-temperature melting) to extract the valuable metals.

For more vast knowledge check out our Books

Market Forecasts, Demand, and Growth

| Source / Research Firm | Base Year & Market Size | Projected Market Size | Forecast Year | CAGR (%) | Notes / Key Highlights |

| MarketsandMarkets | USD 5.41 billion | USD 56.87 billion | 2032 | 17.0% | U.S. market expected to grow rapidly with the highest CAGR |

| Fortune Business Insights | USD 3.79 billion (2023) | USD 23.21 billion | 2030 | 22.75% | Strong growth due to EVs & energy storage systems |

| Grand View Research (U.S.) | USD 374.28 million (2023) | USD 23.21 billion | 2030 | 38.1% | U.S. market expected to grow rapidly with highest CAGR |

The rapid growth of the lithium-ion battery recycling industry is being fueled by electric vehicle adoption, rising battery production, energy storage deployment, and strategic focus on resource security. Evolving environmental regulations and continuous technological advances are also creating favorable conditions for sustainable recycling growth.

Startups and Entrepreneurs have many opportunities.

The lithium-ion recycling sector is a fertile ground for innovative entrepreneurs and startups. The entire value chain for battery end-of-life management is ripe with opportunities. These include establishing efficient networks for collection and logistics, developing preprocessing technologies (dismantling, sorting, shredding), improving recycling processes (hydrometallurgical or pyrometallurgical for greater recovery rates and purity), and developing battery diagnostics.

Developing software and data analytics platforms to track the lifecycle of batteries and providing policy and consulting services is also a significant opportunity. This sector focuses on creating a resilient and robust circular economy, encouraging deep innovation and building a future that is sustainable.

Related: Starting a Lithium-Ion Battery Assembly Business: Key Considerations and Challenges

2. Crystalline camphor: Opportunities for Aromatic Products in Diverse Industries

Product Overview

The solid is waxy and white with a strong aromatic smell. It is a terpene that is used mainly for its medicinal properties and distinctive scent. It was historically made from the wood of the camphor laurel, but is now mostly produced synthetically using turpentine. Camphor is used in many industries, including pharmaceuticals and cosmetics. It’s also used for religious ceremonies, as well as a moth repellent.

Camphor’s volatile nature, antiseptic properties and ability to counter-irritate make it an important ingredient in pain relievers and cold remedies. Camphor is also in high demand due to the growing trend of natural products, especially for aromatherapy and traditional medicine.

Market Forecasts, Demand and Growth

| Source | Market Size (Start Year) | Market Size (End Year) | Forecast Year | CAGR (%) | Notes |

| Market Growth Reports | USD 450.26 million (2024) | USD 670.86 million (2033) | 2024–2033 | 4.53% | Estimates steady growth based on therapeutic & aromatic applications. |

| Introspective Market Research | USD 480.69 million (2024) | USD 771.95 million (2032) | 2024–2032 | 6.1% | Provides a more optimistic growth outlook. |

| Allied Market Research (Synthetic Camphor) | USD 395.1 million (2021) | USD 700.9 million (2031) | 2021–2031 | 6.0% | Focuses only on synthetic camphor segment. |

This growth is largely due to its increasing use in cosmetics, personal care products, aromatherapy, and traditional medicine, as well as religious and cultural practices.

Opportunities for Startups and Entrepreneurs

There are several ways to explore the crystalline camphor market, including developing special formulations that take advantage of its unique properties, focusing on sustainable sourcing and manufacturing, and targeting niche markets (e.g., athletes, elderly population).

There are also opportunities in export and import specializations, R&D investments for novel applications, and the creation of value-added products such as camphor-infused cleaning agents or candles. It is a lot of room for innovative products and market entry strategies, especially for those that can differentiate themselves through sustainability, quality or novel applications.

3. Electrical Conduits (PVC/UPVC/HDPE/FRLS): The Backbone of Modern Infrastructure

Product Overview

Electrical conduits serve as important protective enclosures for wiring in modern electrical systems. Electrical conduits protect wires and cables from damage, including physical impact and moisture. They also shield them against chemicals and rodents. Conduits come in a variety of materials, with each material having distinct advantages depending on the application. Most common types include:

- PVC (Polyvinyl chloride) Conduits are widely used because of their affordability, ease of installation, and excellent resistance against corrosion, chemicals, or moisture. These lightweight, flexible, and non-conductive conduits are suitable for residential, underground, and commercial applications.

- UPVC (Unplasticized Polyvinylchloride) Conduits: A rigid and more robust version of PVC that offers superior mechanical strength and resistance to UV radiation. Preferred for outdoor installation and direct burial when greater physical protection is needed.

- HDPE Conduits (High-Density polyethylene): Highly valued for their outstanding strength-to-density ratio, flexibility and superior resistance against chemicals and abrasion. Ideal for telecommunications projects, power distribution and civil engineering, particularly trenchless installation methods such as directional boring.

- FRLS Conduits (Flame Retardant, Low Smoke): Engineered for minimal smoke and toxic fumes to be released during an emergency. This is essential for environments that are safety-critical, such as hospitals and data centers.

The choice of conduit material is influenced by the environmental conditions, mechanical requirements, cost and regulatory standards.

Market Forecasts, Demand and Growth

| Source | Market Segment | Year/Period | Market Value (USD) | CAGR (%) | Forecast Year |

| Grand View Research | Global Electrical Conduits | 2023 | 7,436.4 million | – | – |

| Grand View Research | Global Electrical Conduits | 2024–2030 | 11.68 billion | 6.7 | 2030 |

| GM Insights | PVC Electrical Conduits | 2024 | 2.9 billion | – | – |

| GM Insights | PVC Electrical Conduits | 2034 | 5.7 billion | – | 2034 |

The construction industry is booming, as are smart cities, renewable energy projects and safety regulations.

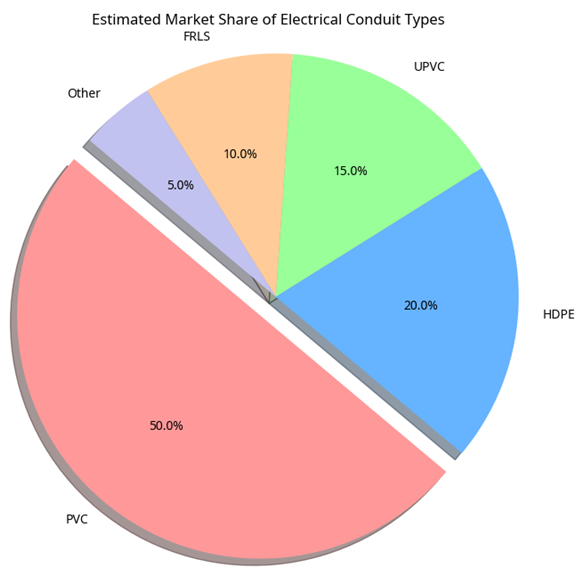

Estimated market share of electrical conduit types

PVC conduits are the most popular due to their affordability and versatility. HDPE is gaining traction for specialized applications. FRLS, on the other hand, is becoming more important in fire-sensitive areas. This pie chart shows an estimated distribution of the market based on current trends.

Entrepreneurs and startups have many opportunities.

The electrical conduit distribution and manufacturing sector provides a wide range of opportunities for entrepreneurs and startups. There are many opportunities in the electrical conduit manufacturing and distribution sector. Smart conduit systems that have embedded sensors and optimize distribution and supply chain, as well as consulting and training, are all promising options. Markets are ripe with innovation that improves safety, sustainability and installation efficiency.

Related: Feasibility and Techno-Economic Viability Study on PVC Coated Wires & Cables Industry

4. Modular Switchplates (Polycarbonate/ABS). Aesthetics and functionality meet.

Product Overview

Modular switchplates are a major leap forward for electrical fittings. They offer enhanced aesthetics, unmatched flexibility and increased safety over traditional switchboards. Modular systems, unlike fixed-gang switchplates, allow users to customize their arrangement of sockets, dimmers and other electrical accessories on a single plate. Modularity allows for a great deal of design flexibility and can be adapted to the needs of users and interior designs.

The plates are primarily made of high-quality engineering materials: polycarbonate (PC), for its exceptional strength, durability and impact resistance. This makes them ideal for areas with high traffic. ABS (Acrylonitrile Butadiene Styrene), for its balance between impact resistance, toughness and aesthetic appeal. It offers a cost-effective option, as well as a smooth and glossy finish. Both materials can be molded into a variety of shapes, sizes and colors. They are also easy to install and maintain.

Market Forecasts, Demand and Growth

| Source | Market Segment | Year/Period | Market Value (USD) | CAGR (%) | Forecast Year |

| Dataintelo | Global Modular Switches | 2023 | 2.81 billion | – | – |

| Dataintelo | Global Modular Switches | 2023–2032 | 4.13 billion | ~ Healthy CAGR | 2032 |

| Reportprime | Global Modular Switches | 2020 | 1.20 billion | 7.0 | – |

| Reportprime | Global Modular Switches | 2020–2030 | 1.95 billion | 7.0 | 2030 |

The key factors that have contributed to this growth include the evolution of architectural and interior design, the seamless integration of smart homes, safety and durability being prioritized, an increase in renovations and remodeling, and ease of installation and upkeep.

Opportunities for Startups and Entrepreneurs

The modular switch plate market offers exciting opportunities for aspiring entrepreneurs. This includes focusing on design innovation and aesthetics, developing and integrating smart modules (e.g. Wi-Fi Wi-Fi-enabled switch, USB-C charger ports), and exploring advanced, sustainable or new materials (e.g., antimicrobial surfaces). There are also opportunities to offer customization and bespoke services, leverage e-commerce models and direct-to-consumer models, as well as provide installation and consulting services. Markets value innovation, quality and smart features. This offers significant market influence.

5. Lab-Grown Diamonds From Graphite: The Future of Gemstones & Industrial Applications

Product Overview

Lab-grown diamonds are also called synthetic, cultured or engineered diamonds. They are real diamonds that have been produced in a controlled lab environment, rather than being extracted from the ground. They are identical in terms of chemical, physical, and optical properties to their natural counterparts. Carbon is the primary raw material used to create these diamonds. It’s most often derived from graphite, which is a high-purity form of carbon. Their creation is based on two main methods:

- High-Pressure/High-Temperature (HPHT): This method mimics natural diamond formation, subjecting graphite to immense pressures (around 5.5 GPa) and high temperatures (around 1,300-1,600 °C) with a metal catalyst. The carbon from graphite crystallizes on a diamond seed, growing to a larger diamond.

- Chemical Vapor Deposition: This method involves placing a diamond crystal seed in a chamber that is filled with carbon-rich gases (such as methane). Microwaves are used to break down the gas molecules. This allows carbon atoms to crystallize and precipitate onto the diamond seed, layer by layer.

The popularity of lab-grown diamonds is growing in the jewelry industry. They are an affordable and ethical alternative to natural diamonds. They also have many industrial uses due to their superior optical, thermal, and hardness properties.

Market Forecasts, Demand, and Growth

| Aspect | Details |

| Market Size (2022) | USD 24.0 billion (Allied Market Research) |

| Market Size (2023) | USD 22.79 billion (Fortune Business Insights) |

| Projected Market Size (2024) | USD 25.89 billion (Fortune Business Insights) |

| Projected Market Size (2032) | USD 74.45 billion (Fortune Business Insights & Allied Market Research) |

| Alternative Projection (2032) | USD 59.2 billion (Allied Market Research) |

| CAGR (2023–2032) | 9.6% (Allied Market Research) |

| Industry Analyst View (GIA) | Significant share of diamonds expected to be lab-grown by 2025 |

The following are powerful drivers: ethical and sustainable sourcing; enhanced affordability and value proposition; continuous technological advances leading to higher-quality products and services, increased acceptance and mainstream adoption; and expanding industrial applications.

For more informational knowledge check out our related videos

Opportunities for Startups and Entrepreneurs

Lab-grown diamonds are a dynamic and lucrative sector for entrepreneurs. The opportunities include setting up and scaling HPHT and CVD production plants, specializing in colored or industrial diamonds, as well as providing cutting, polishing and certification services. The key to success is developing innovative retail and jewelry models, developing industrial applications via R&D, partnering, and creating strong marketing and brand strategies. Recycling carbon sources to produce diamonds further improves sustainability. This sector is a great way to disrupt traditional markets and contribute to a sustainable future.

Discover the Right Business for You With Our Startup Selector Tool

FAQs (Frequently Asked Questions)

Q1: What is the main driver for the Lithium-Ion Battery Recycling Market?

A1: The market’s growth is driven by several factors, including the increasing demand for electric cars (EVs), the growing global battery production, the evolving regulatory landscapes that promote circular economy principles, as well as the need to secure vital raw materials.

Q2: What is the difference between natural and synthetic camphor?

A2: The wood of the camphor tree is used to produce natural camphor, while synthetic camphor comes from turpentine. The two produce the same chemical compound, but they are derived from different sources.

Q3: What are the benefits of FRLS electrical conduits in modern construction?

A3: Why are FRLS conduits important for safety-critical areas? A3: Because they are designed to prevent the spread of fire, and emit as little smoke and toxic fumes as possible. This improves the safety of buildings such as hospitals, data centres, and high-rises during a fire.

Q4: What is the main advantage of using modular switch plates compared to traditional ones?

A4: Modular switch plates provide enhanced aesthetics, increased flexibility and improved safety. These plates allow customization of electrical components within a single switch plate. They simplify installation and maintenance, and are made from durable materials such as polycarbonate or ABS.

Q5: Are laboratory-grown diamonds diamonds?

A5: Lab-grown diamonds look, feel, and behave exactly like natural diamonds. These are real diamonds. They differ only in origin. They were created in a laboratory, not from Earth.

Q6. What are the main methods of producing lab-grown Diamonds?

A6: The two primary methods are High-Pressure/High-Temperature (HPHT), which mimics natural diamond formation, and Chemical Vapor Deposition (CVD), where carbon atoms crystallize onto a seed from carbon-rich gases.

Q7: How does NPCS support new businesses?

A7: Niir Project Consultancy Services assists entrepreneurs through the preparation of detailed Techno-Economic Feasibility Reports and comprehensive Market Surveys. These reports include crucial information such as manufacturing processes, raw materials, plant layout, and financial projections. They help entrepreneurs evaluate the viability of their industrial ventures.