The infrastructure sector is growing quickly, increasing the demand for durable and reliable piping solutions. Ductile iron pipe fittings are among the most dependable materials used in water supply, sewage systems, and industrial networks. These fittings are crucial for connecting ductile iron pipes and ensuring robust, leak-free systems that can last for decades. For entrepreneurs and startups venturing into the manufacturing field, ductile iron pipe fittings present significant opportunities. This article covers the market outlook, growth potential, manufacturing process, and why this business can be a worthwhile venture.

Understanding Ductile Iron Pipe Fittings

Ductile iron is a type of cast iron known for its strength, flexibility, and toughness. Its unique microstructure has nodular graphite, providing better resistance to impact and pressure compared to traditional cast iron. This makes ductile iron a great material for pipe systems where durability and long service life are essential.

Types of Pipe Fittings

Pipe fittings made from ductile iron include bends, tees, reducers, couplings, and flanged adapters. These fittings connect different sections of piping, change direction, or allow branching in networks. They are used in drinking water supply, wastewater management, fire protection systems, irrigation, and industrial piping applications. Their corrosion resistance, high-pressure capacity, and cost-effectiveness make ductile iron pipe fittings a key element in important infrastructure projects.

Market Outlook and Growth Potential

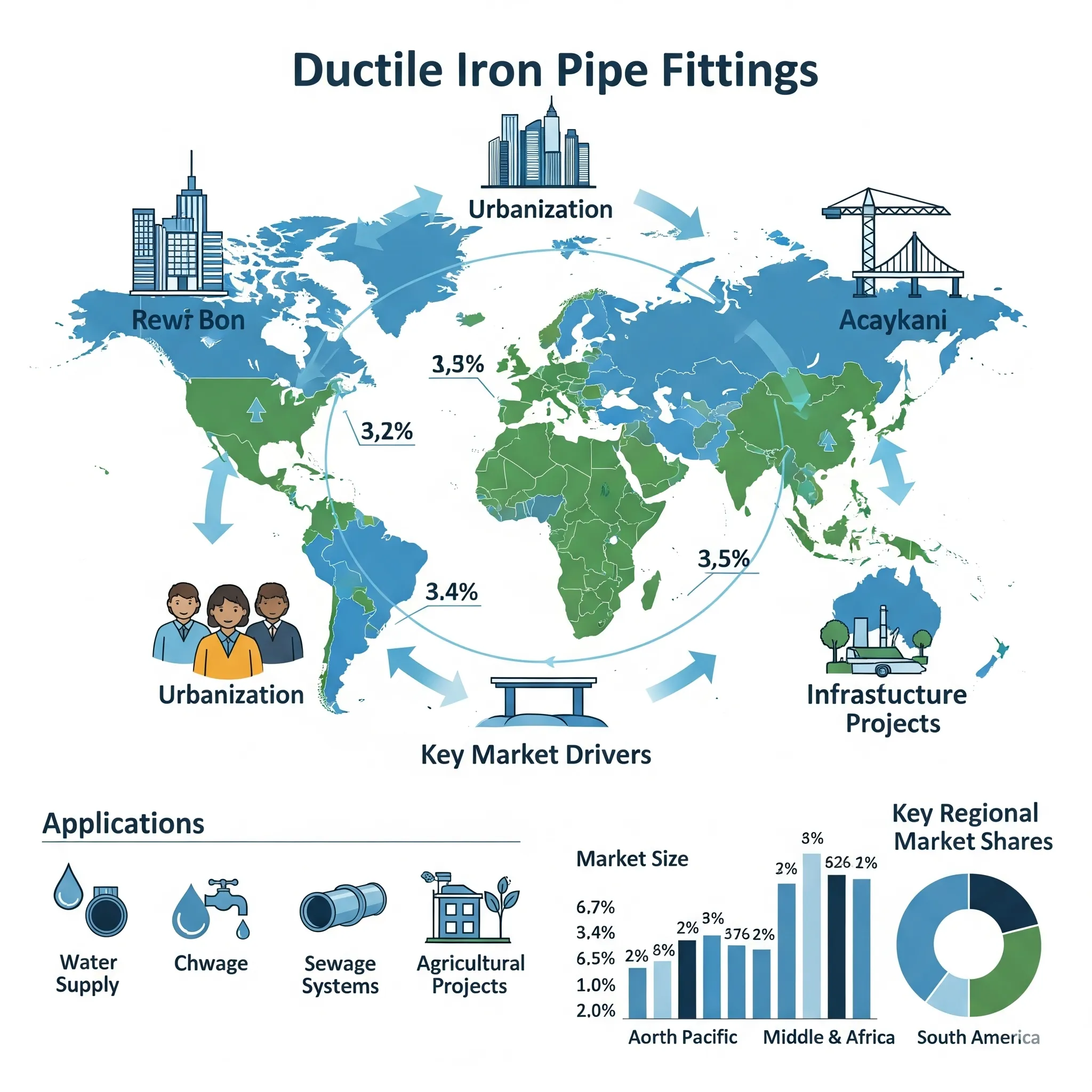

The global market for ductile iron pipe fittings is expanding steadily, driven by urbanization, population growth, and large-scale infrastructure projects. The increasing need for reliable water supply and efficient sewage systems leads to consistent demand for ductile iron products. Municipal corporations, industrial plants, and agricultural projects all heavily depend on ductile iron piping networks.

Regional Growth

Research indicates that the global ductile iron pipes and fittings market is set to grow at a steady rate over the next decade. The Asia-Pacific region remains the largest market due to rapid urban development and water infrastructure growth in countries like India and China. North America and Europe also play significant roles, fueled by pipeline replacement projects and the modernization of aging infrastructure.

Sustainability Factor

The rising focus on sustainable infrastructure and the use of long-lasting materials further enhances demand. Ductile iron fittings are recyclable, making them environmentally friendly choices compared to some plastic alternatives. With government investments in water supply and wastewater treatment facilities, demand for ductile iron pipe fittings is expected to stay strong even during economic downturns.

For more information, check out our project report

Key Demand Drivers

Several factors contribute to the sustained need for ductile iron pipe fittings. The main driver is the global push for better water infrastructure. As urban populations increase, cities require stronger networks for water distribution and sewage management. Ductile iron fittings provide leak-proof systems capable of handling high pressure and large volumes.

Industrialization and Agriculture

Industrialization also increases demand. Factories and processing plants rely on extensive piping systems to transport fluids and gases. The durability of ductile iron reduces downtime and improves efficiency. Additionally, irrigation projects in agricultural regions depend on sturdy pipe fittings to reliably transport water across fields.

Replacement Market

Another demand driver is the growing replacement market. Many developed countries have aging water supply systems made with older materials. Replacing these with ductile iron fittings raises safety standards and cuts cleaning costs. The increasing emphasis on sustainability further promotes the use of ductile iron because it is recyclable and lasts much longer than alternatives.

To explore more, check our books

Manufacturing Process of Ductile Iron Pipe Fittings

The manufacturing process for ductile iron pipe fittings involves several carefully managed steps to ensure product quality. It starts with melting raw materials like pig iron, steel scrap, and alloys in a blast furnace or electric arc furnace. The carbon and silicon content must be balanced to achieve the desired properties.

Transformation into Ductile Iron

Once the molten metal reaches the right composition, magnesium or other nodularizing agents are added to form spherical graphite structures. This step converts regular cast iron into ductile iron by enhancing flexibility and strength. The molten ductile iron is then poured into molds shaped for the required fittings, such as bends, tees, or couplings.

Finishing and Treatment

After the metal solidifies, the fittings undergo heat treatment, shot blasting, and machining. Heat treatment ensures a uniform microstructure and mechanical strength, while shot blasting removes surface impurities. Machining provides precise measurements and smooth surfaces for proper jointing.

Quality Assurance

The fittings are tested rigorously for quality assurance. Common tests include hydrostatic pressure testing, tensile strength measurement, and dimensional accuracy checks. Finally, the fittings receive protective coatings, such as epoxy or cement mortar, to prevent corrosion and extend service life.

Related articles:- The Most Profitable Businesses and Industries for a New Startup. Razor Blade for Safety Razor and Disposable Safety Razor, Disposable Plate and Cups from Waste Rice Husk Powder, Ductile Iron Pipe Fittings, Silicon Metal, Disposable Safety Razors, Medium Density Fiberboard (MDF), and Oxygen Gas Plant (Industrial and Pharmaceutical Grade).

Applications Across Industries

Ductile iron pipe fittings are used across various sectors, making them highly versatile. Municipal water supply projects rely on them for strong and leak-free networks. Sewage treatment plants use them to transport wastewater safely and efficiently. Fire protection systems, which need to resist high pressure, also depend on the reliability of ductile iron fittings.

Industrial Applications

In industrial sectors, these fittings play an important role in moving chemicals, oils, and other fluids. Their strength and resistance to corrosion make them suitable for demanding environments. Agricultural irrigation projects benefit from their long service life and ability to handle varying water pressures. This wide range of applications allows manufacturers to serve diverse markets and reduce dependence on any single sector.

Competitive Advantages of Ductile Iron Pipe Fittings

One of the main advantages of ductile iron fittings is their long service life. With proper installation, they can last more than 100 years, far outlasting many alternatives. Their high tensile and compressive strength enables them to withstand both internal pressure and external loads.

Cost-Effectiveness

Another benefit is their cost-effectiveness. Although the initial investment may be higher than some plastic options, low maintenance needs and longevity make ductile iron fittings more economical over time. They are also easier to install using standard jointing methods, saving time during large-scale projects.

Sustainability

Their recyclability makes them environmentally friendly and supports global efforts to reduce waste and promote sustainable materials. This ensures ductile iron fittings remain important in future infrastructure projects.

Challenges in the Industry

Despite their benefits, ductile iron pipe fittings face challenges. Competition from alternative materials, notably high-density polyethylene (HDPE) and PVC, is strong in some areas. These materials are lighter and easier to transport, but often don’t match the durability of ductile iron.

Rising Costs

Rising raw material costs impact manufacturers as iron and alloy prices fluctuate on global markets. Energy-intensive manufacturing processes also drive up production costs. Maintaining strict quality standards is crucial since substandard fittings can jeopardize entire networks, leading to costly failures.

Innovation Needs

Manufacturers must continuously innovate to improve coatings, cut production costs, and streamline logistics to stay competitive. However, ductile iron’s established reputation as a reliable and durable material provides a strong foundation for the industry.

Market Forecast and Future Opportunities

The outlook for ductile iron pipe fittings is very positive. The growing demand for modern water infrastructure and the replacement of outdated pipelines will ensure steady market growth. Developing economies like India are seeing significant investment in water distribution and sanitation projects, offering strong opportunities for manufacturers.

Technological Advancements

Advancements in manufacturing processes, including precision casting and advanced coatings, will further improve product quality and service life. Export opportunities are increasing as developing nations seek durable solutions for large infrastructure projects.

Smart Cities and Sustainability

The rising focus on smart cities and sustainable development will drive the use of ductile iron pipe fittings. Their recyclability and long lifespan align well with future infrastructure needs. Entrepreneurs entering this sector can gain an advantage by emphasizing quality, sustainability, and reliable supply chains.

Role of Niir Project Consultancy Services (NPCS)

Entrepreneurs interested in the ductile iron pipe fittings business often need expert advice before launching operations. Niir Project Consultancy Services (NPCS) prepares market surveys and detailed techno-economic feasibility reports that provide valuable insights. These reports cover key aspects such as manufacturing processes, raw materials, plant layout, and finances. NPCS helps entrepreneurs evaluate the feasibility of starting new industries or businesses, making it easier to make informed decisions and succeed in competitive markets.

Conclusion

The ductile iron pipe fittings manufacturing business offers a strong opportunity for entrepreneurs and startups. The sector benefits from steady demand, driven by infrastructure expansion, population growth, and the need for sustainable solutions. With applications across municipal, industrial, and agricultural sectors, manufacturers can tap into diverse markets.

By adopting efficient manufacturing practices, ensuring strict quality control, and exploring new opportunities in both domestic and international markets, businesses can achieve long-term success. Despite challenges like raw material price fluctuations and competition from alternative materials, the durability, reliability, and sustainability of ductile iron fittings ensure their continued importance.

For entrepreneurs ready to enter a high-demand and future-oriented industry, ductile iron pipe fittings manufacturing offers both stability and growth. With strong market prospects, proven material advantages, and increasing infrastructure needs, this business stands out as one of the most promising manufacturing opportunities today.

Discover the best business ideas for yourself using our startup selector tools.

Frequently Asked Questions

What are the key raw materials needed for manufacturing ductile iron pipe fittings?

The primary materials are pig iron, steel scrap, and ferroalloys, such as ferrosilicon and magnesium ferrosilicon, which are crucial for producing ductile iron.

What is the typical manufacturing process?

The process generally involves melting the raw materials in a furnace, treating the molten iron with magnesium to make it ductile, casting the fittings in sand molds, and then finishing steps like cleaning, heat treatment, pressure testing, and applying a protective coating.

What are the major challenges in this business?

Key challenges include high capital investment for machinery and facilities, fluctuating raw material costs, and stringent quality control and standards required for public utility projects.

What are the primary markets for these fittings?

The main markets are municipal water supply and sewage systems, irrigation projects, and industrial applications. Demand is driven by infrastructure development and the need to replace aging pipelines.

How is quality control ensured?

Quality control is crucial and involves several tests, including chemical composition analysis of the molten iron, hydrostatic pressure testing to check for leaks, and dimensional checks to ensure the fittings meet required specifications.