In today’s society, chemical recycling and solvent recovery are essential. The industries produce large quantities of waste each day. Many of these can be harmful to the environment if they are not properly treated. The traditional recycling methods cannot handle all waste types, particularly chemicals and solvents. These services can help. These services focus on recovering and reusing valuable chemicals. This reduces pollution and saves resources while supporting sustainable manufacturing.

What is Chemical Recycling?

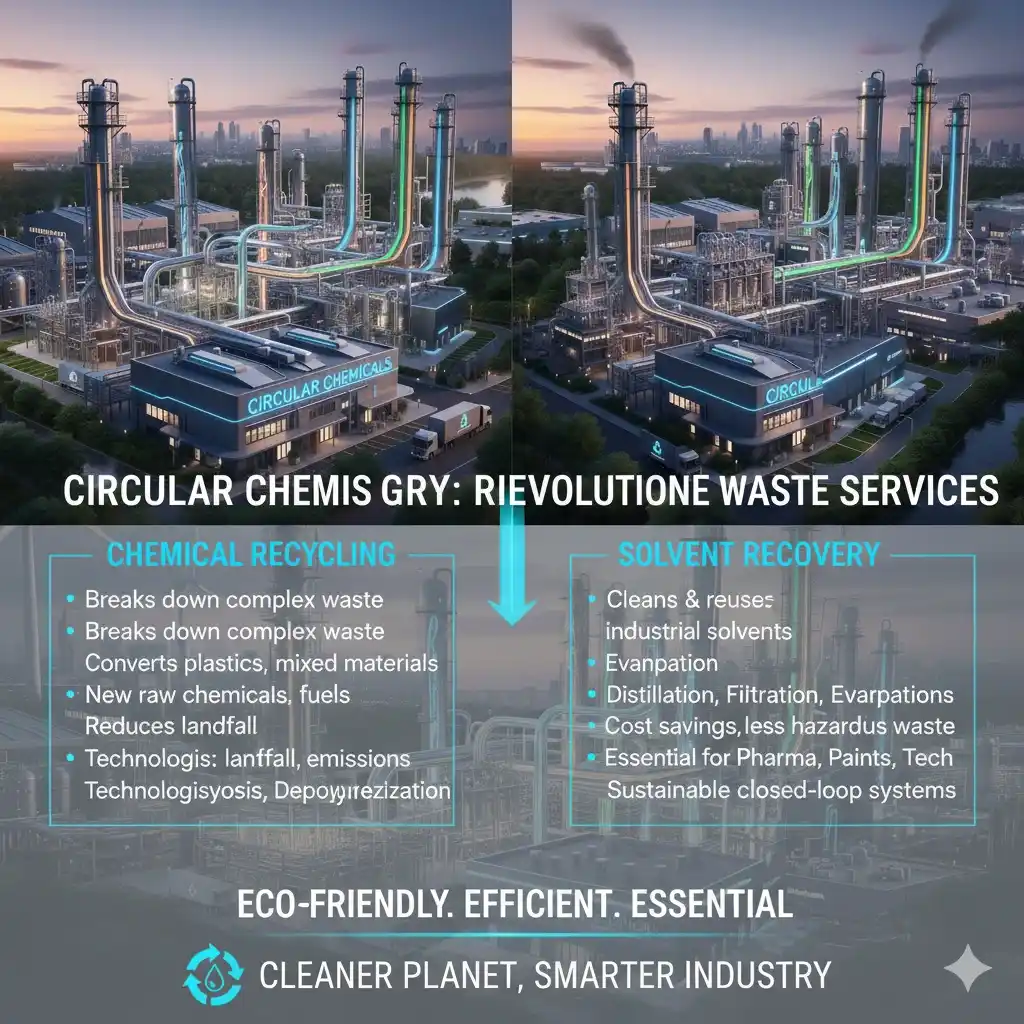

Chemical recycling takes trash. Especially tough plastics and breaks it down to the basics. Unlike regular recycling, which just cleans and reuses stuff, this method turns garbage back into oil, gas, or raw chemicals. It works on messy, mixed-up waste that normal recycling can’t handle.

Companies use advanced tech like pyrolysis and gasification for this. These tools break down even the dirtiest, most complicated junk. By doing this, factories don’t need as many new materials, and that shrinks their impact on the environment. Less waste, less pollution. It’s a win for everyone except the landfill.

Read More: Startup Ideas Based on India’s Growing Demand for Bulk Industrial Solvents

Why chemical recycling is important

The limitations of traditional recycling methods make chemical recycling important. Mechanical recycling is not possible for many items such as contaminated materials and packaging. These items are often disposed of in landfills, or they are burned causing pollution. This problem can be solved by chemical recycling, which turns them into valuable products.

Chemical recycling is kind of like giving old junk a second shot at life, and guess what? It seriously helps cut down on those pesky greenhouse gases. Instead of always making brand new stuff, companies can just reuse what’s already out there. It saves a bunch of energy, too. It’s all about keeping things in the loop, like one big recycling party where nothing goes to waste. So, businesses get to hit their green goals, help the planet, and even save some money. Pretty sweet deal, if you ask me!

Read More: How to Start an EV Station Franchise: A Complete Guide for Entrepreneurs

Understanding Solvent Recovery

Solvent recovery is a process that allows industries to reuse valuable resources. Solvents can be liquids that are used to dissolve substances or extract them. Many industries, including pharmaceuticals, paints and coatings, chemicals, use solvents. Solvents are expensive and can harm the environment when they are wasted.

Solvent recovery systems are designed to capture and clean used solvents before reusing them. Solvents can be cleaned by using methods like filtration, distillation and evaporation. It reduces the cost of hazardous waste disposal and the need for new solvents. Reusing solvents also reduces environmental risks associated with solvent production and disposal.

Solvent Recovery Services: Benefits

The benefits of solvent recovery services are numerous for businesses as well as the environment.

- Cost savings: Companies can save money by using recovered solvents rather than buying new ones.

- Reduction of Waste: Recovery reduces hazardous waste sent to landfills and incinerators.

- Environment Protection: Reusing Solvents reduces pollution and conserves resources.

- Compliance with environmental regulations: Many nations have strict environmental laws. Solvent recovery can help industries adhere to these rules.

- Better Sustainability: Recovery Programs support eco-friendly practices. It enhance the reputation of a business.

How these services work together

Chemical recycling and solvent recover services are often closely linked. Chemical waste and solvents are produced by many industries. Combining these services allows companies to create a complete waste management system. A pharmaceutical company, for example, may can recycle its chemical wastes. It can recover solvents that were used during manufacturing. It not only saves money, but it also creates a safer and cleaner work environment.

These services push companies to stop messing around with chemicals. The more businesses focus on cleaning up, the less mess they have to deal with. Plus, they save money and hit their environmental targets faster. Honestly, it’s a no-brainer.

Read More: Starting a Chemical Packaging Plant for Drums and Carboys

Industries that Benefit Most

Chemical recycling and solvent recovery are a vital part. It helps to be environmentally friendly and competitive.

- Pharmaceuticals Drug production requires complex chemicals and solvents. Recovery services cut waste and costs.

- Paints and Coatings: Paints & coatings companies recover solvents and use them again. They cut down on hazardous waste at the same time.

- Petrochemical Industry: Petrochemical plants crank out loads of chemical waste. They need to recycle if they want to stay sustainable.

- Electronics Manufacturing: Recycling chemicals in production reduces environmental damage and recovers valuable material.

- Plastic Manufacturing: Plastic makers use chemical recycling to break down waste plastics. They turn that junk into fresh raw materials.

Technology Behind the Services

Advanced technologies are required for both chemical recycling and solvent recoveries.

- Distillation Common method to separate contaminants from solvents.

- Filtration Removes solid particles to make solvents recyclable.

- Pyrolysis Heat is used to break down plastics and convert them into fuels or raw chemicals.

- Gasification Turns waste into syngas that can be used for energy or chemicals.

- Depolymerization Breaks polymers down into their original monomers to be reused.

The methods used by the industry allow them to safely recycle and recover even the toughest wastes.

Read Our Book: Click Here

Environmental Impact

These services actually help the environment in big ways. They send less waste to landfills by using chemical recycling and solvent recovery. Reusing materials takes less energy than making new stuff. That means fewer greenhouse gases and less use of water and fossil fuels. Plus, these services keep hazardous chemicals out of soil and water.

Business Advantages

These services offer companies financial benefits in addition to environmental ones. Chemical recycling and solvent recovery can reduce material costs for businesses. The businesses can also save money on hazardous waste disposal fees.

Companies that invest in environmentally-friendly solutions also improve their image. Customers prefer to purchase from companies that are concerned about sustainability. Recycling and recovery services are a wise investment to ensure long-term success.

Read Our Project Report: Click Here

Recycling and Recovery: The Future

Chemical recycling and solvent recovery are about to blow up—finally. People care about the planet now, and governments are cracking down with tough new rules. Industries can’t just do whatever they want anymore. They have to clean up their act and switch to greener methods, whether they like it or not.

Tech is getting slicker every day. We’re not just talking about tossing bottles in a blue bin—now we’ve got robots running recycling plants and high-tech gadgets sniffing out every bit of valuable material. It’s like CSI for your trash.

With all this new gear, companies can pull way more useful stuff out of their waste instead of just dumping it. The whole idea? Build a world where nothing gets tossed—everything gets reused, again and again. Basically, a circular economy. No more waste, just endless do-overs.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

Chemical recycling and solvent recover services are vital for a sustainable future. These services allow industries to reuse resources, reduce waste and lessen environmental harm. These services are a win-win for all parties. They not only save the environment but also businesses money. Chemical recycling and solvent recovery are set to play a bigger role. Because technology advances and environmental awareness keep growing.

Chemical Recycling And Solvent Recovery Services: Frequently Asked Questions

1. What is the difference in chemical recycling and mechanical Recycling?

Mechanical recycling is a cleaner and more efficient alternative to chemical recycling. It does not change the structure of materials. Chemical recycling is better for mixed waste or contaminated materials. It can’t be recycled mechanically.

2. How much is solvent recovery?

Solvent recovery is not always cost-effective. Although there is an initial cost for equipment, the company will save money by reusing and recycling solvents.

3. These services are safe for workers.

Yes. Professional recycling and recovery companies use the latest safety equipment and measures. Workers are protected by safety protocols and proper training.

4. All types of plastic can be chemically recycled

Although not all plastics are recyclable chemically, the technology is improving. Chemical recycling is already possible for many plastics such as polystyrene and polyethylene.

5. What are the environmental benefits of these services?

They save energy and reduce pollution of air, water and soil. They also conserve natural resources and promote sustainable development.