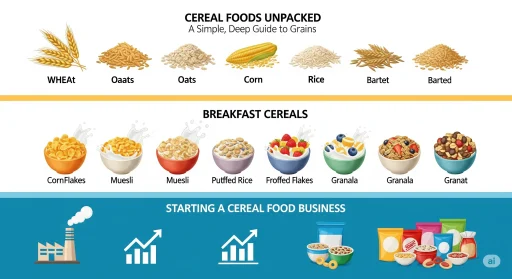

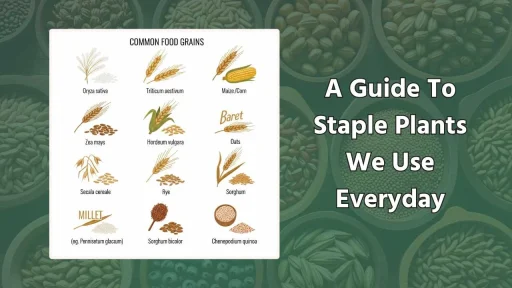

Cereals are the staple food of the world. We eat them as a snack, for breakfast and in many other meals. Cereals are made from grains such as wheat, rice corn, oats, and millet. These grains are processed into flour, porridges, baby cereals, flakes and puffed snacks.

This article will explain what cereals are and how manufacturers make them. Let’s discuss food safety, quality, and business steps for starting a cereal factory. You can also find useful links to the industry that you can use when planning a project.

What Are Cereal Foods

Cereal grains are the source of cereal foods. Cereal grains include wheat, rice and corn. They also contain minerals, fiber and some protein. Cereals are popular with families because they provide energy, can be stored well and can be made into a variety of products. Cereals include staples like rice, chapati and pasta, as well as processed foods such corn flakes and muesli. Cereal products are also the basis of many infant foods, convenience foods, and other foods.

Cereal Foods: Key Categories

Sort cereal foods into three categories: raw grain products (raw grains), hot cereals (hot cereals), and ready-to eat cereals.

- Raw grain products: Mills clean, hull, and grind grain into flour.

- Hot cereals: Hot cereals include porridge or oatmeal that is cooked with milk or water. Hot cereals require minimal processing, but controlled drying and packaging.

- Ready-to-eat (RTE) cereal: RTE cereals are processed differently so that they can be eaten with milk, or as a snack.

Health And Nutrition Basics

Whole grain cereals retain the germ and bran. Whole-grain cereals contain more minerals, vitamins and fiber than refined alternatives. Cereal foods are often fortified with iron and vitamins to improve nutrition. For example, breakfast cereals and baby cereals usually contain added nutrients. Choose whole grain or low sugar RTE cereals. Check the label to see if there is added sugar and fiber.

Read Our Book: Profitable Agro Based Projects with Project Profiles (Cereal Food Technology) (2nd Revised Edition)

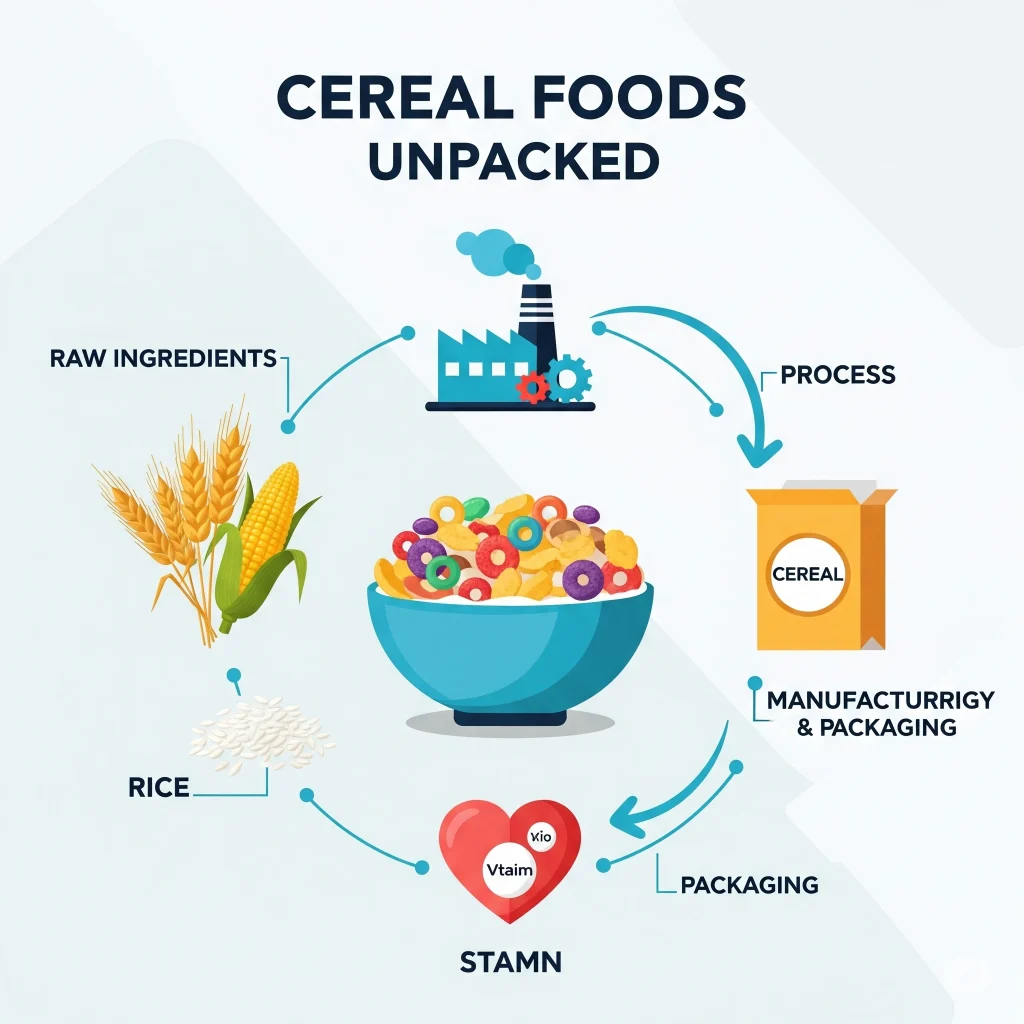

How Cereals Are Processed – Step-by-step

Cleaning and sorting: The first step in the cleaning process is to clean the grain, removing dust, stones and broken grains. Sorting and cleaning raw grain is done by machines using sieves and compressed air.

Grinding: Mills are used to grind grains into flours or cereal bases. The roller mills and the hammermills are used to grind grain into the correct size.

Cooking and conditioning: Processors cook grain or dough to produce products such as corn flakes, extruded snack foods and other snacks. Cooking alters the starch content of grains and shapes the final product. Before shaping, add moisture or steam to the product.

Shaping and forming: The producers shape cereals in a variety of ways, including rolling (to create flakes), extrusions (to produce puffed shapes), and flaking (for the rice flakes). Extruders are machines that push dough through dies at high temperatures and pressure to create crunchy or puffed snacks.

Drying and toasting: After shaping the product, it is placed in a toaster or dryer. The cereal will stay crisper and fresher if you dry it.

Coating, flavoring and fortifying: The producers may add chocolate, sugar, vitamins or minerals. Coating adds a taste and shine. Fortifying cereals or baby foods with nutrients is a good way to make them more nutritious.

Packaging and sealing: Cereals are placed in pouches, tubs or boxes and sealed tightly to maintain freshness. Labels on packaging include information about ingredients, expiry dates and nutrition.

Every Plant Must Ensure Food Safety And Quality Control

- Check the raw grain for moisture and pests.

- Watch the temperature and drying time to prevent undercooked or burned batches.

- Check the microbial count, especially in baby cereals and RTE.

- Separate the raw and cooked zones and keep them clean to prevent contamination.

- Metal detectors, sieves and lab tests are all used to ensure product safety and consistency.

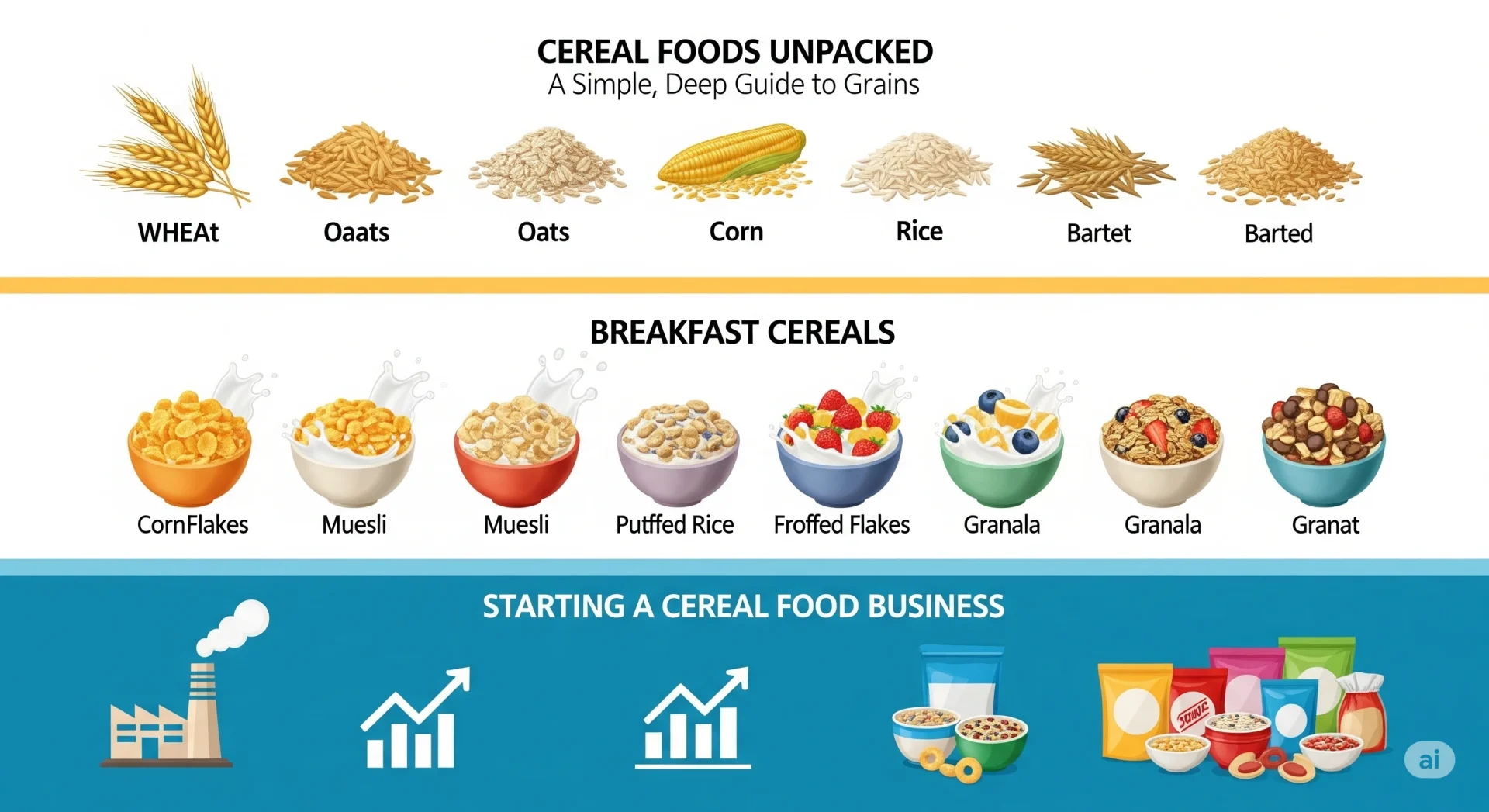

Basic Equipment And Layout For A Small Cereal Factory

For a starter cereal factory, you will need cleaning machines, mills and grinders, extruders and flakers, cooks and dryers, coating machines and packaging machines. You may also require a lab to test the products. The layout should be designed to allow for a smooth flow of raw materials storage, cleaning, processing, drying and packing. Separate staff zones and food zones to comply with hygiene regulations.

Buy quality grain from reliable suppliers. To prevent mold, keep moisture levels low when storing grains. RTE cereals should be sourced with ingredients that are free of coatings, vitamins, and flavors. Local sourcing reduces transport costs and makes supply more reliable.

Corn Flakes Manufacturing Plant – Complete Project Guide — practical production steps and costs: Click here

Start-up Costs Vary With Scale

Costs for project planning and cost considerations (practical). Larger lines are more expensive but produce less, while smaller lines have a lower cost per unit. Land or rent, equipment and packaging machinery, initial stock of raw materials, staff, and land are all major costs. A project report can help you get realistic cost estimates and equipment lists. For example, a cereal processing report will assist in preparing a bankable business plan. You can find a project outline in a Project report dedicated to cereal processing. You can find a suitable NIIR resource for project reports below.

Simple Tactics For Marketing Cereals And Cereal Foods

- Sell at local supermarkets, online shopping sites and grocery stores.

- Free samples are available at supermarkets and fairs to allow customers to try the product.

- To attract health-conscious buyers, use labels that clearly state “whole grain”, “fortified”, or “no additional sugar”

- Bulk supplies are available through schools and cafes.

- Use social media to share your brand story – local grain, family recipes, eco packaging, etc.

Simple steps for waste management and sustainability Use broken flakes and husks to feed animals or compost. Save energy by recovering heat from dryers. When possible, use recyclable packaging. These steps will reduce costs and increase your brand’s appeal to environmentally-conscious consumers.

Breakfast Cereal Corn Flakes Production – production overview and business idea

Quick Fixes For Common Problems

- Cereal that is soggy: Increase drying time or reduce package moisture.

- Check the storage conditions and quality of raw grains to determine if they are causing an off-flavor.

- If the size or shape is not consistent, adjust your extruder settings or roller settings.

- Improve seal quality and test pouches.

A Quick Checklist For New Entrepreneurs

Choose your product line (cornflakes, puffed-rice, baby cereal). Create a small-business plan, including costs and sales targets. Get the necessary licenses for food safety. Find local grain suppliers and choose a small production. Test recipes, run a small-scale market pilot and gather feedback. Then, scale up gradually.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion

Cereals offer a steady demand, a wide variety of products and opportunities for new businesses. Customers will be loyal to producers who put quality, nutrition, safety and marketing first. Adopt simple sustainability measures, use practical processing methods, and control quality. Plan a cereal factory and use a detailed project report and a detailed plan to make the best financial and technical decisions.

Cereal Foods: FAQs (Quick Answers)

What is the healthiest cereal?

Whole-grain cereals with high fiber and low sugar are best.

Can small plants make baby cereal?

Yes, but they must follow strict hygiene and nutrient rules.

How long do RTE cereals last?

Typically 6–12 months if stored dry and sealed.

Is cereal manufacturing profitable?

Yes, with good quality, marketing, and cost control, it can be.