Cement is a powerful, yet silent enabler of the progress of civilization. This gray powder, which was used to build ancient Roman aqueducts, has been a key component in shaping our cities and connecting our nations. It also supports economic growth. Cement is an essential component of industrial, housing and infrastructure development. Cement manufacturing, particularly in developing economies such as India, is more than just a business opportunity. It’s also a long-term industry that will continue to grow.

This guide will take you through the entire process of starting a business in cement manufacturing, including market dynamics, growth potential, manufacturing processes, sustainability practices and operational considerations.

The Cement Industry Landscape

Cement is a very dynamic industry. It’s one of the oldest and most established in manufacturing. Asia is the largest producer of cement globally, producing more than four billion tonnes per year. India produces over 350 million tonnes of cement each year. It is the world’s second-largest cement producer, after China. This is not an accident. It is due to the availability of raw materials, a large domestic market and a strong distribution and consumption ecosystem.

In India, the cement industry is divided between integrated cement plants that handle the entire production cycle from limestone mining to packaging and grinding units which convert clinker into cement for regional markets. This structure allows for flexibility in scaling operations depending on the proximity of markets and the availability of raw materials.

Related: Feasibility and Techno-Economic Viability Study on Cement Plant

Market Demand and Growth Forecast

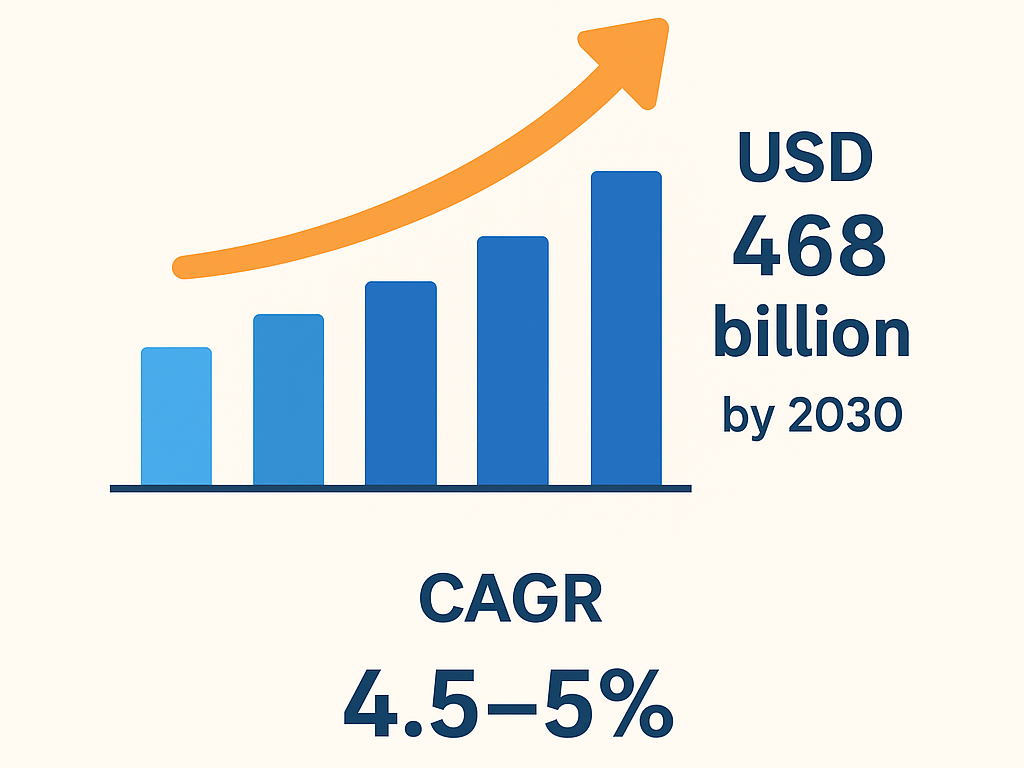

The pace of industrial growth, infrastructure construction and housing is directly related to cement demand. Globally, market growth is expected to increase from USD 370 Billion in 2025 to USD 468 billion by 2030. This represents a CAGR of 4.5-5 %. This growth is fueled by rapid urbanization and government-led infrastructure programmes, as well as the increased adoption of sustainable building materials.

India’s outlook could not be more positive. Cement demand will rise by 6-7% annually in the next five-year period due to government projects such as the National Infrastructure Pipeline and the Bharatmala Road Development Program. Consumption could reach 500 million tonnes annually by 2030.

India’s urban-rural demand mix is what makes the market so attractive to new players. While cities are responsible for high volumes of consumption in large-scale projects and housing, rural areas and smaller towns contribute through irrigation and road construction.

The Key Drivers for Cement Demand

The housing construction industry in India is the largest cement consumer, with over 60% of total demand. The government’s drive to provide affordable housing under schemes such as the Pradhan Mantri Awas Yojana ensures a steady flow of cement projects. Infrastructure development, such as roads, bridges and airports, is also a major driver.

The industrial growth is also a factor, since new factories, energy plants, and warehouses require both structural cement and specialized varieties. This combination of factors creates a large and diverse demand base, which reduces the risk that new players will be unable to enter a market.

Cement Types and Their Applications

Entrepreneurs who are looking to set up a cement manufacturing facility must be familiar with the different types of cement on the market. The most popular variety of cement for general construction is Ordinary Portland Cement. Portland Pozzolana Cement, which contains fly ash and is more durable, is becoming increasingly popular. Portland Slag Cement is made from by-products of steel mills, and offers both durability and strength.

White cement is used for architectural purposes, while sulphate-resistant cements are suitable for marine and chemical environments. The product mix you choose can have a significant impact on your market reach and profitability.

Cement Manufacturing Process

Cement is made by a series of carefully controlled steps that are designed to guarantee consistency, strength and durability of the final product. The process begins with the extraction of essential minerals such as limestone, clay and others from quarries. The raw materials are first crushed to reduce their size, and then blended according to specific proportions in order to produce a uniform raw mixture. The mixture is then fed into a kiln where the intense heat (often over 1450 °C) triggers a series of chemical reactions which produce clinker. Clinker is an intermediate product in cement.

After cooling, the clinker mixture is added with gypsum to improve performance and control the setting time. The final grinding reduces the material into a fine powder that is packaged in bags, or shipped bulk to be distributed. Although the process appears straightforward, it requires precision in terms of quality control, energy management and environmental compliance.

Related: 15 High-Demand Manufacturing Startup Ideas for MSMEs and New Entrepreneurs

Sustainability in Cement Manufacturing

Cement production is an energy-intensive process and has been traditionally associated with high carbon emissions. Modern plants adopt technologies that minimize environmental impact, without compromising on quality. Waste heat recovery systems convert excess kiln energy into useful power. Biomass and municipal solid waste are alternatives to coal that can be used in part.

By using supplementary cementitious material such as fly ash or slag, you can reduce the clinker content and lower emissions. Building sustainability into the production models from the beginning is not only a way to meet regulatory requirements, but also boost brand value with environmentally conscious customers.

Location and resource considerations

The location of a cement factory is important for both operational efficiency and cost control. The proximity to limestone quarries can be critical as the cost of transporting this bulky material long distances is prohibitively high. For uninterrupted production, it is important to have access to a reliable power supply and sufficient water resources. Plants should be situated near major transport hubs or target markets to reduce distribution costs and guarantee timely deliveries. Before settling on a location, entrepreneurs should also consider the local environment, available skilled labor and community relations.

Regulatory Compliance

To establish a cement production facility, you must navigate through multiple regulatory approvals. Both mining and plant operations must have environmental clearances, which cover aspects such as air quality, emissions, and waste management. State Pollution Control Boards are responsible for issuing certificates of Consent to Establishment and Consent To Operate, which must be obtained in order to operate legally.

For raw material extraction it is necessary to obtain mining leases, and the product must meet Bureau of Indian Standards (BIS), specifications. Early engagement with regulatory agencies can help smooth the process and avoid costly delays.

For more information check out this Handbook on Cement, Asbestos, Ceramics, Bricks, Limestone and Construction Materials Manufacturing

Cement Market Competition

In India, the cement industry is dominated largely by well-known names such as UltraTech, ACC, Ambuja and Shree Cement. Regional and specialized players have opportunities. New entrants are able to differentiate themselves by offering superior quality, reliable distribution channels, and targeted marketing in underserved regions.

Eco-friendly cements and specialty varieties are also becoming popular among architects, contractors and infrastructure developers. It is important to build a network of dealers and distributors in order to penetrate the market and ensure consistent sales.

For more information, check out this video

Future Industry Trends

The cement industry evolves to meet the changing needs of construction and environmental standards. Regulation and consumer demand are driving the acceptance of low-carbon cement formulas. The digitalization of the cement industry is gaining traction, as automation and AI-based systems improve efficiency, preventive maintenance and quality monitoring. The location of decentralized grinding units is being pushed closer to the demand centers.

This reduces logistics costs while improving supply responsiveness. Circular economy methods, like using industrial wastes as raw materials, are becoming more mainstream. Entrepreneurs who embrace these trends will have a better chance of long-term success.

Niir Project Consultancy Services can help

Cement manufacturing is a complex business that requires a thorough understanding of the industry, careful planning and a well-defined execution strategy. Niir Project Consultancy Services offers detailed Techno Economic Feasibility reports that cover all aspects of project planning. They are experts in preparing detailed manufacturing processes, raw material requirements and plant layout designs.

NPCS helps entrepreneurs make informed decisions and reduce risk by objectively assessing whether it is feasible to set up new industrial units, or expand existing operations.

Find the Best Idea for Yourself With our Startup Selector Tool

The conclusion of the article is:

Entrepreneurs can enter the cement industry, a large and important sector for national development. Well-planned, strategically located plants can achieve long-term profit in India’s market. Understanding the market, securing quality raw materials and complying with regulations are all essential to success in this industry. The cement industry offers a great opportunity for those who are ready to take the plunge.