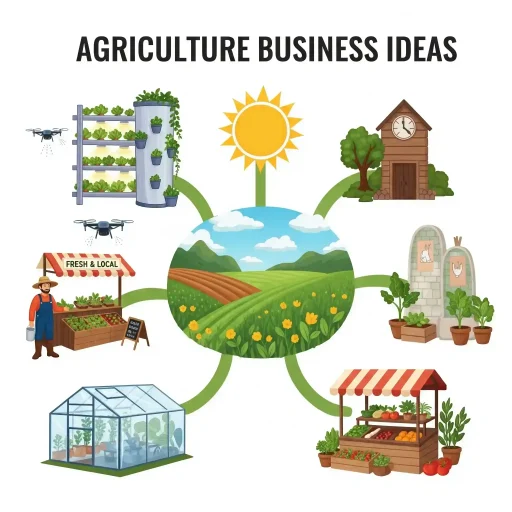

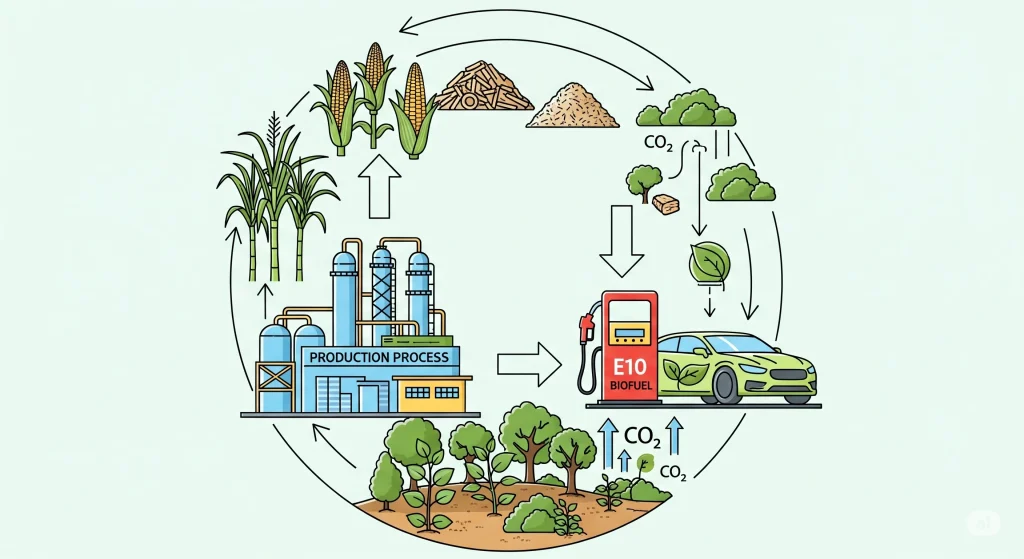

Bioethanol is made from plant material. It is used as a cleaner fuel for motor vehicles, as part of petrol blends (such as E10 or E20) and as a chemical feedstock. Bioethanol is made from waste or crops. When done correctly, this helps to reduce the use of fossil fuels and greenhouse gas emissions.

This article explains bioethanol step-by-step. Let’s know how feedstocks are used, the plant process, equipment that is important, economics, quality, safety and environmental considerations. You can also access a project report and other practical resources for a deeper level of planning.

What Is Bioethanol And Why Is It important

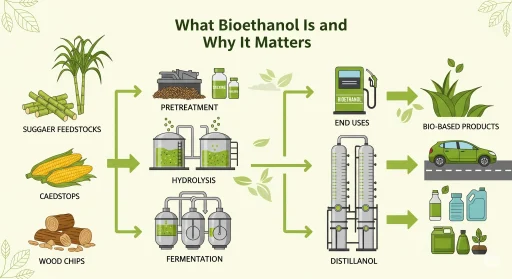

In order to make ethanol, plants are broken down and the sugars produced by this process are fermented. Blending bioethanol with gasoline can reduce the proportion of petrol and lower emissions. It can be produced from sugar crops (sugarcane or molasses), starch plants (corn or broken rice), and lignocellulosic residues (straws, bagasses, wood wastes). The first generation of bioethanol is made from food crops. Cellulosic bioethanol is the second-generation bioethanol that uses non-food waste and biomass. This improves land use and food safety.

How To Select Feedstocks

The best feedstocks for your needs are local, affordable and rich in fermentable starch or sugars. Common options include:

- Sugarcane juice and molasses are both fermentable sugars that require less processing.

- Starch crops, such as corn, wheat and broken rice, require enzymatic hydrolysis in order to be converted into sugar.

- Rice straw, bagasse and wood chips require advanced hydrolysis.

- Food waste, fruit pulp and industrial residues are useful when they’re available in large quantities.

Select a feedstock based on local availability, transportation costs, and policy incentives. Local waste is often used by plants to lower their raw material costs. They also gain social support.

Read More: Producing Ethanol from Corn Starch and Lignocellulosic Feedstocks

Bioethanol Production Process Steps

A typical bioethanol plant follows these stages:

Size Reduction And Pretreatment

Mills and shredders can reduce particle size for lignocellulosic materials. Steam, alkaline or dilute acid pretreatment opens plant cell walls to allow enzymes to reach cellulose and other hemicellulose.

Hydrolysis or saccharification

Starches and cellulose are converted to simple sugars. Amylases are used to convert starches (corn and rice) into glucose. You can use enzymatic or acid hydrolysis to break down cellulose after pretreatment.

Fermentation

Yeast, or microbes specially engineered to ferment sugars, convert them into CO2 and ethanol. The microorganism chosen and the fermentation conditions (temperature and pH) have an impact on speed and yield. Many plants use batch or continuous fermentation methods.

When you’re ready to build your venture, check the NIIR books category for better growth.

Distillation and Dehydration

The fermentation process produces a diluted ethanol broth (8-12% v/v) The distillation process concentrates the ethanol up to 95-96%. The plant uses molecular Sieves or azeotropic Distillation to remove water in order to reach fuel grade (>99%, or hydrous requirements).

Effluents and by-products handling

Spent grains (bagasse) can be used as animal feed, compost or biogas feedstock. Wastewater needs treatment–biological treatment or anaerobic digestion recovers energy and reduces pollution.

Blending and finishing

The pure ethanol is blended or denatured according to local fuel standards.

The equipment you’ll need

An industrial bioethanol plant uses:

- Units for handling feedstock and size reduction (shredders or mills)

- Pretreatment reactors and continuous steam explosion units

- Hydrolysis and enzyme dosing tanks

- Fermenters with temperature control (stretched tanks or continuous fermenters).

- Distillation columns (molecular sieves, azeotropic or azeotropic systems)

- Heat recovery systems that use biogas and bagasse as fuel

- Wastewater treatment: Anaerobic digestion, aerobic treatment, and sludge treatment

- Storage tanks and mixing facilities

Read More: The Profitable Business of Producing Ethanol from Waste Grains

Scale And Layout Impact Costs

Small-scale demonstration plants are cheaper than commercial units. The cost drivers are distillation and dehydration, steam generation and wastewater treatment. The cost of feedstock, steam and power consumption, enzymes and yeast, and revenue from co-products such as distillers’ grains and electricity from biogas should be included in a good project plan. Find ready-made project blueprints with equipment capacities and cost estimates. These are useful for planning finance and permits.

Fuel Standards And Quality Control

Fuel Ethanol must meet purity and impurity levels (methanol, water, and traces of Sulphur). The plants monitor the fermentation efficiency, residual glucose, ethanol titer and impurity profiles. Each batch is tested by an analytical lab for alcohol, density and contamination levels. It is important to meet national fuel standards, including blending specifications, before selling fuel to distributors.

Social And Environmental Considerations

Bioethanol is a fuel substitute that reduces petrol consumption, but has some environmental consequences. To avoid deforestation and fuel-versus-food conflicts, it is important to grow feedstock sustainably. If you want to reduce emissions, use waste feedstocks or co-generate electricity from residues. To avoid contaminating rivers, treat wastewater. Modern plants sequester CO2 and valorize spent solids for animal feed, or use it as industrial fuel.

Safety, Regulations And Basic

Alcohol is flammable. For plants, it is necessary to have explosion-proof electrical systems in the distillation area, as well as safe storage tanks and fire suppression system. Respect local laws regarding fuel registration, acquisition rules, environmental permits and worker safety. Plan for the safe storage and transportation of raw feedstock as well as finished fuel.

Economics of business models

Examples of common business models are fuel plants that sell blended ethanol to oil firms, merchant ethanol used for industrial purposes (solvents and sanitizers), or integrated biorefineries that produce ethanol and higher-value chemicals. Co-products (carbon dioxide, distillers’ dried grains, electricity) improve margins. Financial viability is dependent on the feedstock price, ethanol production, energy costs, and government incentives such as blending mandates or taxes breaks.

If you’re building a bioethanol manufacturing business, you can explore a full-scale report that covers feasibility, cost breakdowns, machinery lists, and financial projections. NIIR offers a detailed Bioethanol Manufacturing Plant Project Report that’s tailored to the bioethanol (lignocellulosic biomass) industry.

Cost-Saving Sustainability Measures

Recycle water and use biogas or bagasse to power boilers. This reduces utility bills and the carbon footprint of the plant. Using second-generation feedstocks can often improve net sustainability metrics.

Common Problems And How To Fix Them

- Check for low fermentation yield by checking enzyme activity, pH and temperature, as well as yeast health.

- Cost-effective energy: Add heat recovery, cogenerate using bagasse or biogas.

- Implement a staged biological treatment with solids separation.

- Sign contracts with multiple suppliers to avoid seasonal feedstock shortages. Store dry feedstock in a safe place.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion

Bioethanol plays a significant role in cleaner transportation and local energy security. A successful plant will use the right feedstock and follow robust processes (pretreatments, hydrolysis, fermentations, distillations, dehydrations), recover energy, manage waste, and meet fuel standards. A detailed project report and a focus on sustainability and economics can make the difference between an unsuccessful pilot and a successful commercial operation. You can use the project resources linked to create a thorough feasibility study, and start conversations with suppliers of technology and equipment.

Bioethanol: FAQs

What feedstock should I pick first?

Choose the feedstock that is most affordable and abundant in your area. Molasses and sugarcane juice require simpler processing. Waste grains and lignocellulosic remnants, however, need a more complex pretreatment.

How much ethanol can I expect to get from a ton of feedstock?

Yields are different: sugar feedstocks will convert directly, giving high yields. Starch feedstocks require conversion and have moderate yields. Lignocellulosic feedstock yields depend on the efficiency of pretreatment. Model your expected yields using a project report.

Do I require a special permit to sell fuel grade ethanol?

No. Fuel ethanol is subject to national fuel and excise regulations. Before production, obtain environmental permits and fuel distribution approvals.

Is second-generation bioethanol commercially viable?

Yes. But it requires higher capital costs and enzyme costs. The cost of enzymes and capital costs will decrease as waste is available in greater quantities.