Introduction: Biodiesel Manufacturing is a Strategic Opportunity

Biodiesel Manufacturing has been thrust into the spotlight by the global need to switch from fossil fuels and to cleaner sources of energy. Biodiesel is both a necessity in India, where the economic growth drives a constant increase in energy consumption. This is a biodegradable, renewable fuel that can easily be produced from local resources that are underutilized or thrown away. This is not just an environmental initiative for entrepreneurs or startups. It is also a viable business model aligned with sustainability goals and addressing urgent energy needs.

The versatility of biodiesel is its main advantage. It can be used to power diesel engines that are already in place without requiring significant modifications. The market for biodiesel production in India has expanded as government policies support renewable energy initiatives.

Biodiesel: Its Potential for Business

Transesterification is a chemical reaction that produces biodiesel. In this process, oils or fats react with alcohol (commonly Methanol) under the influence of a catalyst to create fatty acid-methyl esters (FAME), and glycerin byproduct. Biodiesel is made from these methyl esters, which are a cleaner-burning alternative to petroleum diesel. It emits less carbon monoxide and unburned hydrogen.

Over the past decade, India’s biodiesel market has grown, thanks to government incentives, higher crude oil prices and increased awareness of environmental sustainability. The National Policy on Biofuels set the stage for increased blending mandates for diesel, which ensures a stable market for producers. Biodiesel has a strong export potential, as many countries around the world are trying to reach their renewable fuel goals.

Related: Biodiesel Production from Algae

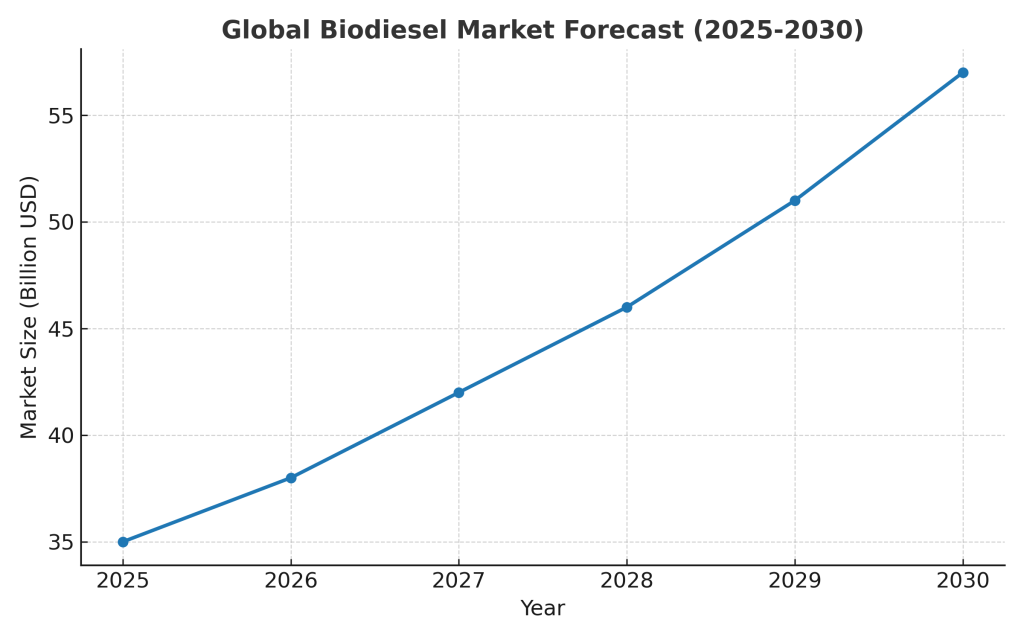

Market Forecasts and Growth Outlook

Biodiesel production in India has a very positive outlook. According to current market estimates, demand is expected to continue growing steadily until 2030. This will be supported by industrial adoption and commercial transport fleets as well as rural energy programs. India’s biodiesel demand is projected to reach 450 million litres in 2025 with a growth rate of more than 7% per year. Demand could reach 700,000,000 litres by 2030. This represents a strong compound growth rate, which reflects policy support and market readiness.

Corporate sustainability commitments are also driving this upward trend. Biodiesel is being used by large transport and logistics companies to reduce their carbon emissions. Other industries, such as mining and railways, are also exploring the use of biodiesel in place of conventional fuels.

Source Raw Materials for Biodiesel Manufacturing

Biodiesel is made from a wide range of feedstocks, which allows entrepreneurs to select those that are both locally available and economically feasible. In India, non-edible oil such as neem and mahua is commonly used, particularly in areas where these crops are abundant. Other oils, such as soybean oil and palm oil can be used, but their availability and market prices will often determine whether they are suitable.

The low cost of waste cooking oil makes it a very attractive feedstock. It also offers many benefits for waste management. In partnership with food processing units, hotels and restaurants, collection networks can be established. Algae oil is another option that offers high yields on a hectare, but requires specific extraction and cultivation technologies. Biodiesel production can be adapted to regional conditions in India because of the flexibility in sourcing feedstock.

View our Related handbooks

The Biodiesel Production Process

The process of establishing a biodiesel plant includes a series of operations to transform the raw feedstocks into fuel-grade Biodiesel. Pre-treatment is the first step in the process. Raw oils or fats will be cleaned and filtered, removing impurities like water, solids and free fatty acid that can interfere with production efficiency.

Transesterification is the core stage, where the feedstock reacts in the presence a catalyst such as sodium hydroxide (or potassium hydroxide) with methanol. This reaction breaks the triglyceride molecule in the oil down into methyl ester (biodiesel), and glycerin. After the reaction, the mixture settles and the layers of biodiesel and glycerin are separated.

The biodiesel then undergoes purification, which involves washing it with water in order to remove any remaining catalyst, soap or contaminants. It is then dried to remove moisture and ensure it meets fuel standards. The biodiesel has been refined and is stored in tanks that are ready to be blended or used directly. The main byproduct is glycerin. This can be sold in industries that produce soap, cosmetics and pharmaceuticals.

Related: 10 Most Successful Startup Ideas

Infrastructure and Plant Layout: Considerations

The layout of the plant is crucial to the success and efficiency of biodiesel production. The plant layout will typically include areas for storage of feedstock, reaction vessels, washing and drying tanks, quality control laboratories and storage of finished products. To ensure the safe storage and processing glycerin, it is also necessary to have areas for handling byproducts.

The design of the plant should be based on maximizing operational flow and minimizing distances between stages. This will reduce handling times and increase efficiency. Automation in certain stages increases consistency and yield while reducing labour costs. To meet regulatory requirements, safety systems, environmental compliance and waste treatment should be integrated into initial design.

Compliance with Regulatory and Quality Standards

To ensure engine compatibility, and to protect the environment in India, biodiesel must meet Bureau of Indian Standards (BIS). The State Pollution Control Board must approve the production of biodiesel, while the Ministry of Petroleum & Natural Gas issues fuel blending standards.

It is important to ensure quality. A poorly produced biodiesel may damage engines and harm the market’s reputation. In-house testing or testing by a third party is therefore essential before fuel reaches the customer. A robust quality control system is essential to ensure compliance and build trust with both domestic and international buyers.

Market Opportunities and Byproduct Utilisation

Biodiesel production offers several complementary opportunities. The glycerin that is produced in the process can be used as a valuable raw material for industrial applications, including food processing, personal care products, and pharmaceuticals. Refining glycerin to sell at higher grades can increase profitability in some cases.

Biodiesel is also a good option for rural electrification, backup power systems and small-scale farm machinery. Entrepreneurs who position themselves as niche fuel suppliers alongside the mainstream markets can diversify their revenue streams and reduce dependence on one buyer segment.

Challenges to Success and Strategies for Success

Biodiesel production is no different. Margins can be affected by significant fluctuations in feedstock prices. Input costs can be stabilized by long-term agreements with farmers, co-ops, or collection agencies. The choice of technology is also important. Choosing proven, efficient production methods reduces operational risk and improves yields.

Many potential customers still do not know the benefits of biodiesel. This gap can be bridged by targeted marketing, demonstrations, and partnerships with fleet operators. Stay informed about the changing biofuel policies. These changes may open up new opportunities for entrepreneurs or force them to adjust their strategy.

Biodiesel Industry: Future Prospects

The Indian biodiesel sector is set to benefit in the future from feedstocks of second generation, such as algae and agricultural waste, which offer higher yields while reducing competition with food crops. Automation and process control advances will increase production efficiency while increased fuel blending mandates can boost demand.

It is possible to create synergies with other renewable energy sources, for example, by integrating biodiesel into larger green hydrogen or biomass initiatives. The best entrepreneurs will be those who invest in technology and remain flexible.

For more information, check out this video

Role of NIIR Project Consultancy Services

NIIR Project Consultancy Services provides professional consulting to prepare detailed techno-economic feasibility reports for new industrial ventures. Therefore, these reports provide entrepreneurs with the information they need to make informed business decisions. They cover everything from the manufacturing process to the raw material requirements and plant layout. NPCS helps clients assess the feasibility of establishing new businesses or industries, ensuring they are based on sound market and technical research.

Find Best Idea for Yourself With our Startup Selector Tool

The Conclusion of the article is:

The production of biodiesel offers a unique combination of profitability and sustainability. It also provides a high-level market security. It is a great opportunity for entrepreneurs who are ready to enter the clean energy industry.

The success of this business depends on the efficient sourcing of feedstock, adhering to quality standards, and smart plant design. It also relies on continuous market engagement. Biodiesel is a key component of India’s move to a greener economy. It will reduce carbon emissions and diversify the energy mix. For entrepreneurs who act now, the rewards could be both financial and environmental–making it not just a business, but a contribution to a cleaner future.