Aluminium is a versatile and recyclable metal that is widely used in manufacturing. It is used in many industries, including construction, consumer goods, aerospace, and automotive. The aluminium industry in India has experienced a remarkable growth, thanks to the Make in India program, increased domestic consumption, and infrastructure development. This has created several opportunities for entrepreneurs who are looking to build sustainable and scalable businesses in the aluminium sector and downstream.

This article takes a look at the best aluminium business ideas. It evaluates the current market, describes the production process, and explains the reasons why MSMEs and startup companies should be paying attention to this sector.

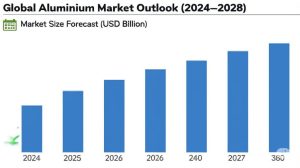

Market Outlook for India’s Aluminium Opportunity

India is one of the top five producers of aluminium in the world. India has experienced a massive expansion of capacity thanks to major players like Hindalco Industries and Vedanta Limited.

India’s annual aluminium production capacity has surpassed 4.1 million metric tons, making it a net primary aluminium exporter. The downstream sector, including fabrication, processing and component manufacturing, is still developing and has untapped potential.

Forecasts indicate that India’s downstream aluminium market will grow by 7.5% CAGR between 2023-2028. The growth of the Indian aluminium downstream market will be fueled by critical sectors such as electric vehicles, renewable energies, defence manufacturing and real estate. There is also room to expand demand, as per capita consumption of aluminium still stands at 2.5 kg (compared with a global average 11 kg).

Aluminium Extrusion Profiles Manufacturing

Aluminium extrusions can be used for a wide range of applications, including construction, solar panel mounting, railway coaches and industrial frames. Extrusion is the process of forcing heated aluminium billets into a die to produce a specific cross-sectional profile.

The business can begin on a small scale, focusing on niche markets such as architectural facades and electrical enclosures. Manufacturers can expand their product range and invest in precision tooling to produce complex profiles as demand increases. This process involves heating the billets to 500 °C and extruding using hydraulic presses. They are then cooled, stretched, and cut to size. Anodising and powder coating are examples of post-processing that add value to the product.

Demand for these profiles has been increasing due to the growing push towards smart cities, green buildings, and infrastructure modernisation. In this market, entrepreneurs who can offer quick turnarounds, quality assurance, and customisation will have a strong business model.

Related: Exploring India’s Role in the U.S. Aluminium Supply Chain

Aluminium Foil and Packaging Unit

Foil is essential in industries like food packaging, pharmaceuticals and cosmetics. It’s also used for household products. Aluminium foil is in high demand due to the growing demand for convenience food and pharmaceutical products exported from India.

To set up a unit for foil production, aluminium slabs are rolled into thin sheets with heavy-duty rolling machines, the foil is annealed until it reaches the desired degree of flexibility and finally slit into different sizes. Entrepreneurs can choose to specialize in different segments, such as blister packaging, laminated aluminum foil for snack food, or industrial insulation wrappings.

Aluminium packaging is becoming more popular as an environmentally friendly alternative to plastics. This trend will benefit manufacturers who have certifications in food safety and pharmaceutical-grade production.

Aluminium Pressure Die Casting Components

Die casting aluminium offers a wide range of possibilities for the production and use of lightweight components in industries such as automotive, aerospace, telecommunications, and household appliances. This process involves injecting aluminium molten into steel dies at high pressure. The result is parts with exceptional dimensional accuracy and finish.

The Indian electric vehicle (EV), electronics, and casting industries have opened up new markets for precision aluminum castings. Entrepreneurs can meet component needs such as engine blocks, gear houses, heat sinks, structural parts, and more. Focus should be placed on optimising mould designs, process control and alloy selection in order to meet mechanical and thermal requirements.

Although the initial investment in die-casting machines and moulds may be expensive, the high volume production makes this an attractive business, particularly when it comes to OEM clients.

Related: How DPC Aluminium Wire Is Made: Step-by-Step Process Explained

Aluminium Utensils and Kitchenware Manufacturing

Aluminum utensils have become a household staple in India due to their affordability and heat conductivity. They are also lightweight. A growing number of African and Middle Eastern nations are also interested in aluminium kitchenware.

The process of manufacturing aluminium products involves melting ingots and casting them into blanks. They are then shaped by pressing or spinning the aluminium, before being polished or anodised. Small units may start with pots and pans while premium segments might offer non-stick or hard-anodised ranges.

Manufacturers can target B2B customers (wholesalers and hotels) as well as B2C clients (retailers) with the right branding, packaging and export certifications.

Aluminium Window and Door Systems Fabrication

Aluminium is increasingly being used in residential and commercial buildings for partitions, doors and windows. It is strong, attractive, resistant to corrosion, and has a high thermal efficiency.

This business involves the sourcing of aluminium profiles, their cutting to size, assembly with glass panels, accessories and installation on site. Entrepreneurs must focus on energy-efficient systems, precision engineering and aesthetic design that meets modern building codes.

A steady stream of orders can be ensured by forming partnerships with interior designers, architects, and real estate developers. Demand is expected to remain strong due to India’s growing urbanisation and real estate sector.

Aluminium Composite Panels Production

ACP sheets are used widely for exterior cladding, interior decoration, and signage in modern infrastructure. The sheets are made of two aluminium plates bonded together with a mineral or polyethene core. They provide durability, weather resistance and a sleek appearance.

Aluminium coil coating machines, panel cutting systems, and lamination machines are required to set up an ACP unit. The capital investment is high but the margins are good, especially when it comes to customised panels that are used in malls, airports, IT parks and metro stations.

Differentiation can be achieved by incorporating design innovation, using fire-retardant materials, or digital printing.

Aluminium Scrap Recycling and Ingots Manufacturing

Aluminium recycling is a growing industry, as environmental sustainability gains in importance. Recycling only uses 5% of energy required for primary aluminum production, which makes it eco-friendly as well as cost-efficient.

Recycling involves collecting and sorting of scrap, shredding it, de-coating it, melting and refining and then casting into standard ingots. These ingots will then be supplied to the extrusion, foil, and die casting units.

The establishment of recycling plants in industrial zones can be beneficial to entrepreneurs. For long-term viability, it is essential to comply with pollution standards and obtain certifications of recycled content.

Aluminium Ladder and Scaffold Manufacturing

The lightweight, strength and corrosion resistance of aluminium ladders and scaffolds make them popular in construction, maintenance and logistics.

Cutting and assembly of extruded profiles is required for the production of various products, such as mobile scaffolds, extension ladders and step ladders. To ensure reliability, safety testing and compliance with BIS/EN standards are essential.

The business model allows for both online retail and institutional sales to be targeted, such as factories, hotels, and municipalities.

Why Aluminium Downstream businesses are attractive to startups

This sector offers a number of advantages to startups and MSMEs.

- Demand for domestic products and exports is strong

- Application across all sectors

- Support for Government through Policies and Incentives

- High Recyclability and Sustainability Value

- Product innovation and brand identity: the scope

With moderate capital, many businesses can be launched and scaled up with demand and specialisation. The sector also benefits from a relatively stable supply of raw materials and technological advances in machinery and automation.

Check our handbook on Aluminium here

Support from the NPCS for Businesses Based on Aluminium

Niir Project Consultancy Services provides market research and detailed project reports tailored for the aluminium and downstream industries. These reports cover manufacturing processes, machinery information, raw material sourcing and financial modelling as well as regulatory requirements. NPCS helps entrepreneurs at all stages of their business, from idea validation through to plant setup and entry into the market.

For more information, check our related video on Aliminium Business

How NPCS Can Help You Start Your Aluminium Business

Starting a business in the aluminium and aluminium downstream sector requires more than just an idea — it demands deep technical knowledge, raw material planning, machinery layout, compliance documentation, and market intelligence. This is where Niir Project Consultancy Services (NPCS) plays a vital role.

NPCS offers comprehensive techno-economic feasibility reports tailored to aluminium manufacturing businesses. These reports cover everything from the raw material sourcing, manufacturing process, equipment selection, plant layout, utility requirements, to financial projections.

Whether you’re planning to set up an extrusion unit, foil production line, die-casting facility, or value-added aluminium composite panel plant, NPCS can guide you through each step. Their expert insights help entrepreneurs minimise risks, optimise investment, and build competitive advantage.

Find the Best Idea for Yourself With our Startup Selector Tool

The Conclusion of the article is:

India’s downstream aluminium sector offers entrepreneurs a profitable, high-growth opportunity. There are many potential businesses, from die-casting and extrusion profiles to recycling and foil packaging. This allows for different levels of investment and capability. Startups and MSMEs that focus on quality, efficiency and market demands can create strong businesses and contribute to India’s economic and industrial growth.

Entering the aluminium industry today could be one the best moves that industrial entrepreneurs can make. With the right guidance, technical assistance, and market insight, it is possible to enter the sector with confidence.