Most people can recall a childhood favorite toy. It didn’t matter if it was a wooden car or a teddy, but that toy made us happy and shaped our world. Imagine being the one who brings that magic to a whole new generation of kids.

Toy manufacturing is a creative and profitable business that lets you turn your imagination into products that kids will love. Learn more about this business.

Understanding Toy Manufacturing Business: From Dream To Reality

It’s not enough to just come up with some ideas. You need a solid business plan, a design that is safe, manufacturing and safety standards, as well as a smart strategy. This guide will provide you with a roadmap. From the moment you have an idea to when your toy is placed on a shelf, we will guide you through every step.

This article is written in an active voice to help you take direct, actionable steps towards building your own toy empire.

Related Story: Start an Electronic Toy Business in India with ₹15–25 Lakh

Step 1: Develop Your Toy Idea

A great idea is the basis of every successful toy. You need to have a vision of what you are trying to achieve before you start manufacturing anything.

Find Your Niche

The toy industry is huge. Toys are not all the same, so it is important to choose one area of focus. You can target a particular audience and stand out. Consider the following popular niches.

- Educational Toys: Toys which teach basic skills such as counting, reading, solving problems, and basic science

- Wooden Toys: Classic, durable and environmentally friendly toys that parents who are looking for sustainable alternatives will love. Plush toys are soft, cuddly toy animals like teddy-bears

- Puzzles And Board Games: Encourage family interaction with these toys that stimulate the mind

- Tech-integrated Toys: Toys that have simple electronics, lights or sounds, and even an app connection

Knowing Your Audience

After you have chosen a niche you need to decide for whom you will make the toy. A toy made for a child of 10 years old is different than one designed for a toddler. Define the age group you are aiming for. The age group you choose will influence the design, materials and complexity of your toy, as well as its safety features.

Create a prototype

You can now bring your ideas to life. Sketch your design either on paper or with computer-aided designing (CAD) software. You must make a prototype after you have finalized the design. A prototype is your first working model.

It can be made by hand, using a 3D-printer, or hiring a professional model maker. You can test the toy for its function, durability, and appearance using a prototype. This is an important step to identify any defects and correct them before mass production.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Step 2: Manufacturing Blueprint. How to Make Your Toys

You are now ready to start your manufacturing process.

Select the Right Materials

- Your choice of materials will determine the quality, cost, and safety of your toys.

- You can use pine, birch or beech for wooden toys. The wood must be smooth and free from splinters.

- You will use polymers such as ABS (for hard, strong toys like building block) or polypropylene to make plastic toys.

- You can choose fabrics such as fleece, felt, cotton or even felt for plush toys. Then, select a stuffing material that is safe.

You must ensure that the materials you use are not toxic and safe for children. It is important to use non-toxic materials, including the paints, glues and finishes.

Related Story: List of Profitable Small Manufacturing Business Ideas with Investment of 50 Lakhs (Plant and Machinery)

Create Your Production Space

A dedicated manufacturing space is required. Start small in your garage or workshop and grow to a bigger factory as you expand. Your space will need the correct machinery. You could use:

- Woodworking Tools (saws, sanders)

- Plastic injection molding machines

- 3D printers to create new prototypes or parts

- Sewing machines for plush toys

- Clean, dedicated area for assembly and paint

Establish Your Production Process

Create an assembly line. This is a step by step process to make each toy.

- Component Creation: you create the individual components of the toy. You may cut wood shapes, mold plastic parts, or sew sections of fabric.

- Assemblage: Your team assembles the individual pieces to create the toy. It could be assembling parts, gluing them together or stitching and stuffing a plush toy.

- Finishing: To finish the toy, you can paint it in non-toxic colours, apply safe finishes and add any final stickers or details.

It is essential to perform a thorough quality control. Every toy must be inspected. You inspect each toy for defects, such as sharp edges and small pieces that can break off and cause choking hazards. You only approve toys which are well-made and safe.

Read Our Book To Grow In Business

Step 3: The Business Engine, Selling Your Toys

A great toy can be made, but that’s only half the battle. It is also important to have a plan for selling it.

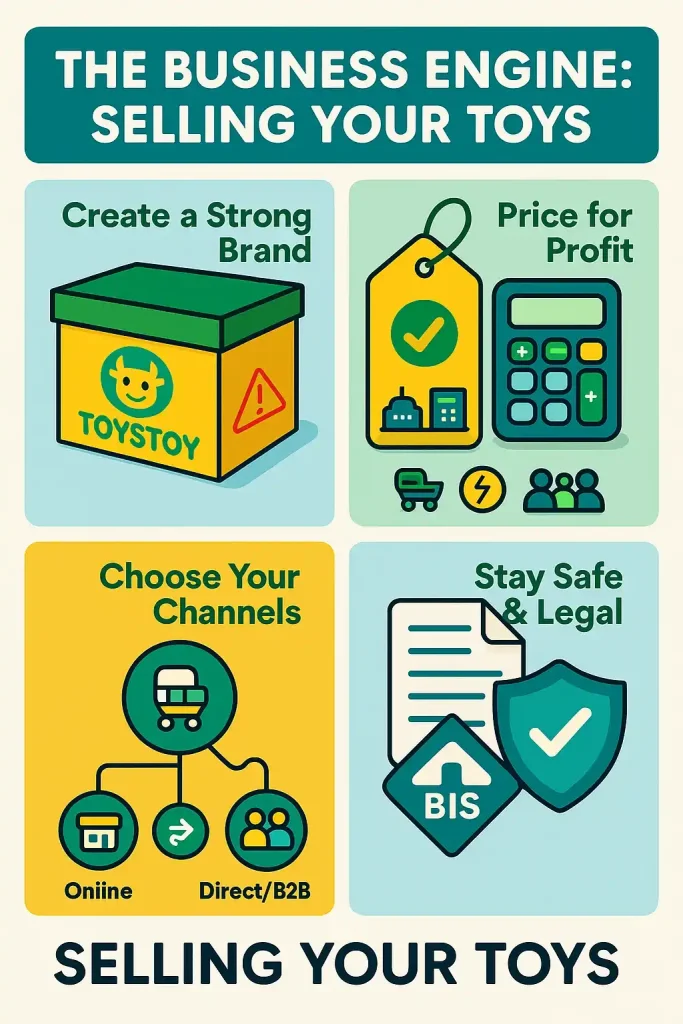

Create a strong brand and great packaging

Your toy business needs a memorable logo and name. Your brand tells customers a story, which helps them trust your products. Packaging is also important. The box of your toy must be durable, attractive and informative. The box should display your brand clearly, include the toy and all safety warnings.

You Can Save Money By Pricing Your Toys Right

Set a price which covers all your expenses and allows you to make a profit. Calculate your costs: materials, rent, labor, electricity and marketing. You can then add a markup on top of your total cost to determine the final price. To ensure that your price is competitive, research what similar toys are sold for.

Choose Your Sales Channels

Decide where and how to sell your toys.

- Online: You can create your own ecommerce website, or sell through popular online marketplaces such as Amazon and Flipkart.

- Offline: You can sell your toys in local toy stores, department stores, and large retail chains.

- Direct and B2B Sales: You can either sell to your customers directly at exhibitions and fairs, or in bulk to daycares and schools.

Manage Legal and Safety Compliance

Your business must be run legally. You must:

- Registering Business: You can register as a private limited company, a partnership or a sole proprietorship.

- Tax Registration: You must register for GST.

- BIS certification: This is the most important license in India. Bureau of Indian Standards has established mandatory safety standards. To test your toys, you must take them to a BIS approved lab. You can only legally sell your toys in the country after they pass these tests.

Know Our Project On Manufacturing

Conclusion

Toy manufacturing is a rewarding business venture that blends imagination and practicality. It is a rewarding experience to create a toy manufacturing business that will bring happiness and help children develop.

From a great idea, you need to create a product that is safe and well-made, then develop a business plan. You can turn your passion for toy-making into a successful business if you prioritize quality and safety over all else.

Toy Manufacturing Business: FAQs (Frequently Asked Questions)

Q1: What amount of money will I need to launch a toy company?

A: The amount of investment varies widely. A small business of handcrafted wooden toys can be started from a home-based workshop for a relatively small investment. A larger factory that uses plastic molding machines will require much more capital for both equipment and space.

Q2: Does the toy business make money?

A: Yes, this can be very lucrative. Finding a niche that is profitable, controlling production costs, producing a product of high quality, and marketing the product effectively are all important factors. Unique and well-designed toys can command higher prices and better profit margins.

Q3: What should you focus on most in your business?

A: Safety. Your number one priority is the safety of children who play with your toys. It is important to adhere to all safety regulations, such as BIS certifications in India. One safety issue can damage your brand and your business.

Q4: How can I make toys at home to start?

A: You can run a small business from your home, particularly if you are making handcrafted toys such as wooden puzzles and stitched dolls. Even if you are running a small-scale business from home, you will need to obtain all necessary licenses and certifications including BIS.

Q5: What can I do to compete with toys imported at lower prices from other countries?

A: You can effectively compete by focusing on the areas where mass-produced imported products often fail. You can differentiate your business by focusing on superior quality, creative and unique designs, eco-friendly and safe materials, and building an established local brand. Today, many parents actively search for high-quality toys that are safe and made locally.