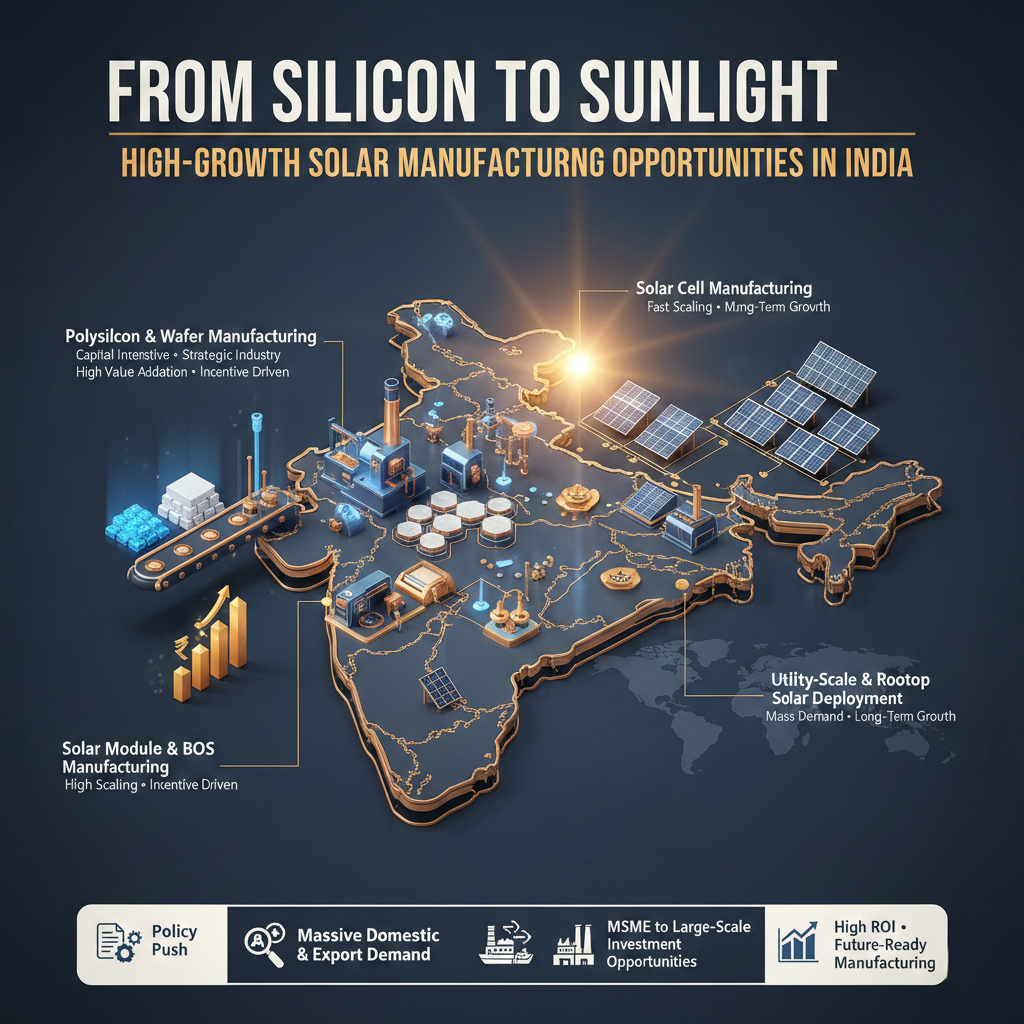

Solar Manufacturing Business in India is going through a remarkable change and one of the things that drive it is the adoption of renewable energy, import substitution, and government-led industrial policies. Solar manufacturing has become one of the most attractive industrial sector, as the country moves towards a clean energy future. The evolving solar industry is majorly characterized by the production of solar cells, manufacturing of silicon metal and assembly of solar panels which together are the different ways to penetrate the market and participate for entrepreneurs, MSMEs, and investors looking for scalable, asset-backed businesses in the renewable energy ecosystem of India.

This guide takes a closer look at these opportunities not only as technological ideas but also as viable factories, balance sheets, and market prospects.

Read More: Investing in Solar PV Module Manufacturing: A Sustainable Opportunity for Startups

Solar Cell Manufacturing: The Heart of Solar Energy

Every photovoltaic system has the solar cell as its heart. Even though the final users are more accustomed to seeing solar panels, the solar cell is the one that assures the effectiveness, the energy output, and the longevity of the whole system. Besides large solar parks, solar cells are necessary in many residential applications such as small rooftop solar panels, agricultural irrigation pumps, telecom towers, electric vehicle (EV) charging stations, and building-integrated photovoltaics (BIPV).

India’s solar capacity is growing very quickly and therefore making cell manufacturing a strategic priority. As of now, a considerable amount of solar cells consumed in India is still being imported. This situation has opened up a vast opportunity for the local business people to take a large portion of the market and at the same time, it is also a good step towards energy security.(Solar Manufacturing Business in India)

Key Aspects of Solar Cell Manufacturing

- Capital and Precision Intensity

Solar cell production is a precise operation, and it thus requires the capital investment, alongside. Due to the complexity and sophistication of the process, it accurately requires the use of very high-priced machines, strict monitoring of the product quality, and clean-room settings to be made. Although the initial investment is considerable, the long-term profitability might be very high if the plants are fully utilized. - Diverse Technology Options

The technologies include traditional multi-crystalline and mono-crystalline cells as well as advanced TopCon (Tunnel Oxide Passivated Contact) and Heterojunction (HJT) cells. The selection of the technology has a direct impact on the efficiency, market competitiveness, and financial aid availability. - Silicon, Silver, and Gases

Silicon wafers, silver and aluminum pastes, special gases, and high-purity water are among the raw materials that will be needed. A committed supply chain will have to be created in order to ensure that the production process runs without any hiccup. - Energy Considerations

Energy is the biggest factor in solar cell production. Planning for captive power generation is very common to save on operating costs and at the same time enhance the reliability of the plant. - Profitability Threshold

The threshold for plant utilization over which profitability expectations are met is given as 75–80%. Hence, efficient operation and continuous quality control are the two main aspects that make financial success possibl.

Silicon Metal and By-Products: The Strategic Industrial Opportunity

The reduction of high-purity quartz in an electric arc furnace produces silicon metal, which has a vast range of applications, going from aluminum alloys, silicones, electronics, and solar-grade polysilicon, through this heavy industrial sector, which being the largest consumer of electricity, the industry, on one hand, requires high-temperature processes and excellent electrical infrastructure while on the other hand, it simultaneously provides strategic advantages through the generation of by-products.

Read More: Solar PV Power and Solar Products Handbook

Why Silicon Metal Manufacturing is Attractive

- Multiple Revenue Streams

The process of manufacturing silicon metal provides besides metals, other by-products like silica fume which, due to its use in concrete and refractory, the supplier can sell and hence, the revenue is diversified and market risk spread. - Consistent Demand

The aluminum, chemical, electronics, and solar industries consume most of the silicon metal, which ensures steady demand; therefore, investors view the sector as resilient and offering long-term growth opportunities. - Operational Efficiency

Installation of modern furnaces that consume energy optimally and recovers by-products has enhanced production profitability even during periods of low demand.. - Strategic Resilience

Silicon metal plants are initially heavy industrial setups, but such factories are indeed long-term resilient investments that provide not only financial but also industrial importance.

Solar Panel Manufacturing: Connecting Factories to Markets

Manufacturers make solar panels from solar cells, assembling them into robust, weatherproof, and deployable modules. Module manufacturing is simpler than cell production but is the interface with the market. Manufacturers sell the panels to EPC companies, solar developers, distributors, and institutional buyers in the power, agriculture, and real estate sectors.

Read More: Solar Power Plant – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost and Revenue

Advantages of Solar Panel Manufacturing

- Lower Capital Requirements

Module assembling is done with a moderate capital investment and has a faster break-even point of getting returns compared to solar cell or silicon metal production. - Simplified Operations

which is making it easy for the first-time entrepreneurs and small companies to venture in, and testing which is making it easy for the first-time entrepreneurs and small companies to venture in. - Volume-Driven Profitability

Big factories are getting both better pricing from suppliers and large-scale production cost advantages, whereas small plants can cater to local or specific markets only. - Flexible Market Entry

Manufacturers of solar panels can produce different types of products for rooftop installations, agricultural pumping systems, or commercial projects, thus giving them the flexibility to operate.

Read More: Solar Panel Manufacturing: 10 reasons why it is a game-changer for startups

Lessons from Indian Industrial Leaders

Large-scale industrialists have influenced the solar manufacturing industry in India, who have proved the need for scale, integration, and control of raw materials through their works.

- Gautam Adani not only got the idea of manufacturing solar power along with power generation but also saw how this method demonstrates the advantages of backward integration.

- Mukesh Ambani was wise to invest in solar materials, thus showing the importance of raw material supply control and the need for a long-term vision.

Takeaways for Entrepreneurs

- Long-Term Commitment

Apart from the short-term incentives, solar manufacturing, to be successful, requires a long-term commitment. The operational depth, supply chain control, and process discipline are the essential aspects. - Replicating Strategy over Scale

Newcomers in the industry should not just match the volume of production but should rather focus on replicating the decision-making logic of the leaders in the industry—integrating the strategy, controlling the quality, and managing the risk. - Structured Feasibility Planning

Companies build sustainable growth on detailed feasibility studies, market surveys, and techno-economic assessments that experts conduct beforehand.

Read More: How to Start a Solar Panel Manufacturing Business

Structured Feasibility and Support Services

People seldom attribute the success in solar manufacturing to pure luck. Structured planning together with the support of professional consultancy services like Niir Project Consultancy Services (NPCS) can offer:

- Market research and demand assessment

- Plant layout and capacity optimization

- Financial projections and risk analysis

Besides, governments, through domestic production incentives, scale-up programs, and supply-chain resilience initiatives, continue to support solar manufacturing. Consequently, these incentives are making India a more and more attractive place for solar manufacturing investment.(Solar Manufacturing Business in India)

Conclusion

People can regard solar cells, silicon metal, and solar panels as the building blocks of the clean energy industry—they are the foundations of different entrepreneurial paths which are scalable industrial platforms. Solar cell manufacturing might be a place where precision engineers can find their niche, asset managers in silicon metal, and market-oriented operators might thrive in solar module assembly. The common factors for success in all segments are structured feasibility, operational excellence, and long-term strategic vision.(Solar Manufacturing Business in India)

India’s solar manufacturing sector not only produces significant growth but also becomes a central player in the country’s transition to a clean, sustainable energy future for those who are ready to invest in planning, execution, and quality. The transition from silicon to sunlight is not merely a technology revolution—it presents an industrial and entrepreneurial opportunity for entrepreneurs to explore.

Frequently Asked Questions (FAQ)

- Is solar manufacturing a good business for beginners?

Yes, especially in solar module assembly and downstream integration. Solar cells and silicon metal plants need super technical skills and a lot of cash. - Which solar manufacturing segment has the quickest break-even time?

The solar panel manufacturing sector usually gets to break-even the quickest as it has lower capital intensity and simpler operational requirements. - How important is technology choice in solar cell manufacturing?

Very much. It has an impact on efficiency, the availability of financing, market competitiveness and the sustainability of the business in the long run. - Will silicon metal plants be stable in the market?

Yes, the introduction of modern furnaces and the proper recovery of by-products will create a scenario in which there will be consistent profits even against the background of price volatility. - Can solar products still be sold from India to foreign countries?

Most certainly, India can sell a portion of its solar modules and silicon derivatives, provided the output is up to the quality and certification standards required by the international market.