Personal Protective Equipment has become one of the most crucial parts of healthcare, industrial safety, and emergency response. The demand for disposable PPE kits surged during the COVID-19 pandemic, and awareness of their importance has continued to grow. These kits extend beyond hospitals; they are commonly used in pharmaceuticals, chemical industries, laboratories, as well as in construction and mining. For entrepreneurs and startups, the PPE manufacturing sector offers a unique chance to merge business growth with social responsibility.

Importance of PPE Kits

A PPE kit usually includes gowns, gloves, face shields, masks, and shoe covers that protect individuals from exposure to infectious agents or harmful substances. Their role in preventing contamination and ensuring worker safety makes them vital in many industries.

Hospitals need them for infection control, while pharmaceutical and biotechnology labs rely on them for sterile operations. Industrial workers in chemicals and construction use them to limit exposure to hazardous agents. The widespread necessity of PPE across various sectors makes this business very sustainable.

Detailed project report

Market Overview and Forecast

The global PPE market was valued at over 80 billion US dollars in 2022 and is projected to exceed 120 billion by 2030, growing steadily. The disposable PPE segment, especially kits used in healthcare and industrial safety, continues to see strong growth as governments and industries put a priority on worker safety and hygiene.

In India, the PPE market has expanded significantly, with exports reaching multiple countries. Government initiatives promoting domestic production have reduced reliance on imports, creating opportunities for local entrepreneurs to set up competitive businesses. Increased health awareness, the development of healthcare facilities, and stricter workplace safety regulations will keep driving this market.

Factors Driving Growth

The demand for PPE kits comes from various factors. The growing global focus on infection control has turned PPE into a standard part of hospital operations instead of just an occasional requirement. The growth of industries in pharmaceuticals, chemicals, and construction also fuels the need for disposable protective gear.

As global supply chains emphasize preparedness for future health crises, many governments are creating stockpiles of PPE. Furthermore, the trend toward single-use disposable kits, which reduce the need for sterilization and lower cross-contamination risks, has gained wide acceptance. All these trends suggest a growing market that is unlikely to slow down soon.

To explore more, check our books

Regulatory Environment

PPE kits are safety equipment that must meet national and international quality standards. In India, manufacturers must follow Bureau of Indian Standards guidelines, while in the export market, certifications from agencies like ISO, CE, or FDA are required. Testing protocols cover resistance to fluids, tear strength, breathability, and comfort.

Maintaining consistent quality is crucial because failures in PPE can directly impact human health. Entrepreneurs entering this field must ensure strict compliance with these standards, as regulatory approvals are vital for building customer trust and accessing international markets.

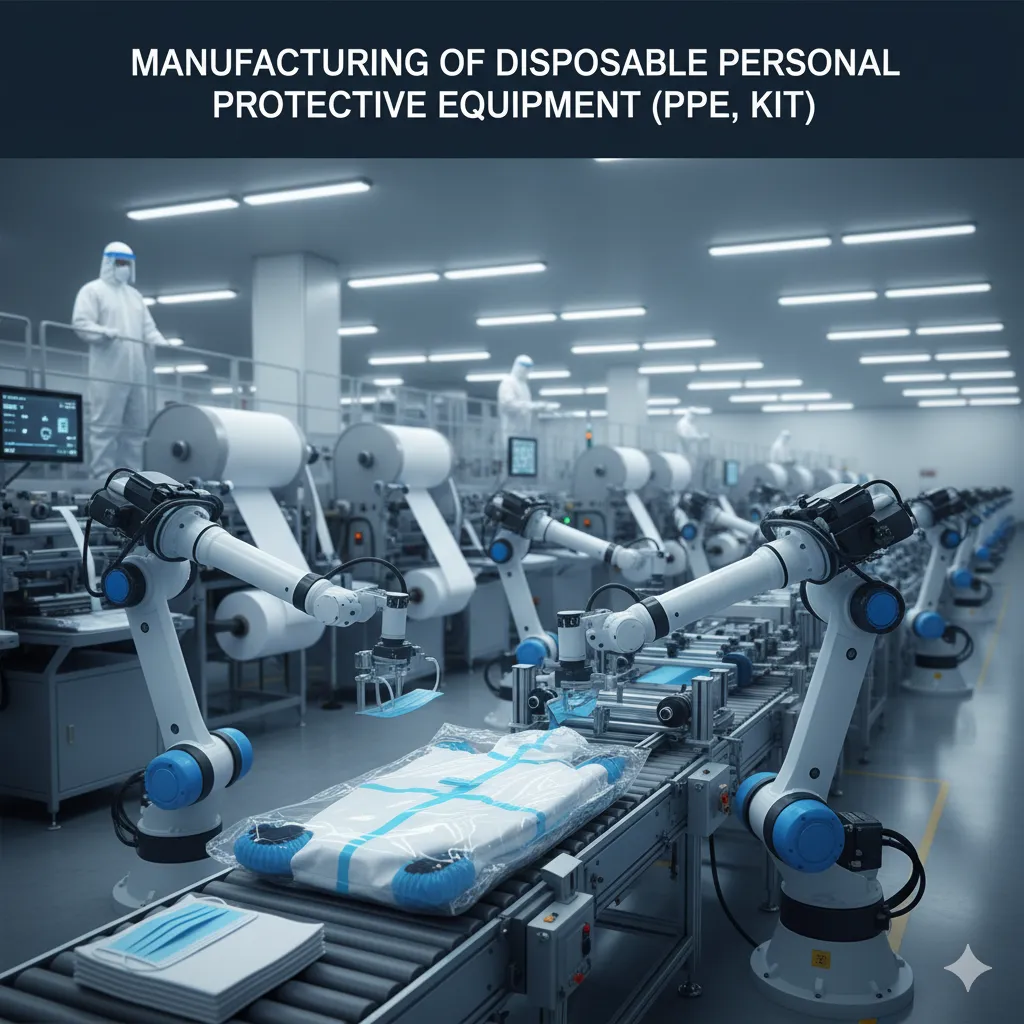

The Manufacturing Process of PPE Kits

Manufacturing disposable PPE kits involves several steps that ensure safety and quality. It starts with selecting raw materials, where non-woven fabrics, melt-blown textiles, and protective polymers form the foundation. These materials are chosen for their barrier properties, breathability, and comfort.

The fabrics are cut into the required shapes using cutting machines and stitched or sealed using ultrasonic technology to make gowns, masks, and shoe covers. Face shields and goggles are produced separately using lightweight polymers and then sterilized. Each component undergoes quality testing for tensile strength, fluid resistance, and user comfort before being packaged into sealed kits under controlled conditions.

Opportunities for Entrepreneurs

The PPE sector provides opportunities in both domestic and export markets. The increasing global emphasis on healthcare preparedness ensures sustained demand. Entrepreneurs can explore niche markets, such as high-quality surgical PPE, industrial protective kits, or specialized gear for chemical industries.

There is also a growing market for eco-friendly disposable PPE made from biodegradable materials, giving startups a chance to stand out. With governments offering incentives for local manufacturing, entrepreneurs in India are well-positioned to tap into both national and international markets.

Related articles:- The Textile and Apparel Sector in India

Challenges in the Sector

The main challenge in PPE manufacturing is maintaining consistent quality while keeping costs competitive. With global players entering the market, price competition can be fierce. Ensuring a stable supply of raw materials is another concern, as non-woven fabrics and melt-blown textiles are critical for production.

Additionally, counterfeit products pose reputation risks, making compliance with certifications increasingly important. Entrepreneurs who focus on innovation, branding, and sustainable practices will be in a better position to tackle these challenges.

Role of Technology and Innovation

Automation and innovation are transforming PPE manufacturing. Advanced non-woven fabric technology improves the barrier properties of gowns and masks. Ultrasonic sealing enhances strength and lowers contamination risks. Sterilization processes have also advanced, ensuring higher safety levels.

Sustainability has become a priority, with research into biodegradable materials for single-use PPE gaining momentum. Startups that invest in these innovations can gain a long-term competitive edge in this evolving market.

Support from Niir Project Consultancy Services

Niir Project Consultancy Services (NPCS) prepares Market Survey cum Detailed Techno Economic Feasibility Reports that cover key aspects such as manufacturing processes, raw materials, plant layouts, and financials. These reports assist entrepreneurs in evaluating the viability of starting PPE kit manufacturing and guide them in establishing successful businesses. NPCS’s expertise helps new ventures enter this highly competitive sector with confidence.

Future Outlook

The PPE market is expected to grow steadily, driven by healthcare expansion, industrial growth, and greater awareness of workplace safety. Demand will also increase as countries prepare for potential pandemics and other health emergencies. The shift toward sustainable and biodegradable PPE represents a new frontier in the industry. Entrepreneurs who focus on innovation, compliance, and quality will capture significant market share and contribute to public health and worker safety on a global scale.

Conclusion

Manufacturing disposable PPE kits presents both a business opportunity and a public health need. For entrepreneurs, the sector offers steady demand, government support, and potential for innovation. By prioritizing quality, abiding by regulations, and adopting sustainable practices, startups can build robust businesses while benefiting society as a whole.

Frequently Asked Questions

What are the key components of a standard disposable PPE kit?

A standard disposable PPE kit typically includes a coverall or gown, a face mask (like an N95 or surgical mask), gloves, a head cover, and shoe covers. Each component is designed to provide a specific barrier against contaminants.

Why is non-woven polypropylene a common material for PPE coveralls?

Non-woven polypropylene is widely used for PPE coveralls because it’s a lightweight, breathable material that provides an effective barrier against liquids and particles. It is also cost-effective to produce and can be treated to be anti-static and water-repellent.

What is the difference between a surgical mask and an N95 respirator?

A surgical mask is a loose-fitting, disposable device that creates a physical barrier between the wearer’s mouth/nose and potential contaminants in the immediate environment. An N95 respirator is a tighter-fitting mask that filters at least 95% of airborne particles, including very small ones.

How are PPE kits sterilized during the manufacturing process?

PPE kits are often sterilized using methods like ethylene oxide gas, which is effective at penetrating the materials to kill bacteria and viruses without damaging the product. This ensures the kits are sterile and safe for immediate use in medical settings.

Why are PPE kits often single-use or disposable?

PPE kits are designed to be single-use to prevent cross-contamination. Once a kit is used in a contaminated environment, it is disposed of to eliminate the risk of transferring pathogens to another person or area.