Are you wondering how they happen from tall and gold oat and cream flakes? If you once had warm oatmeal to start the day, you can think! Oats do not only appear in your grocery box. Interestingly, they undergo a process between traditional agriculture and modern technology.

We let you experience oats from the fields to their final product on your pantry shelves.

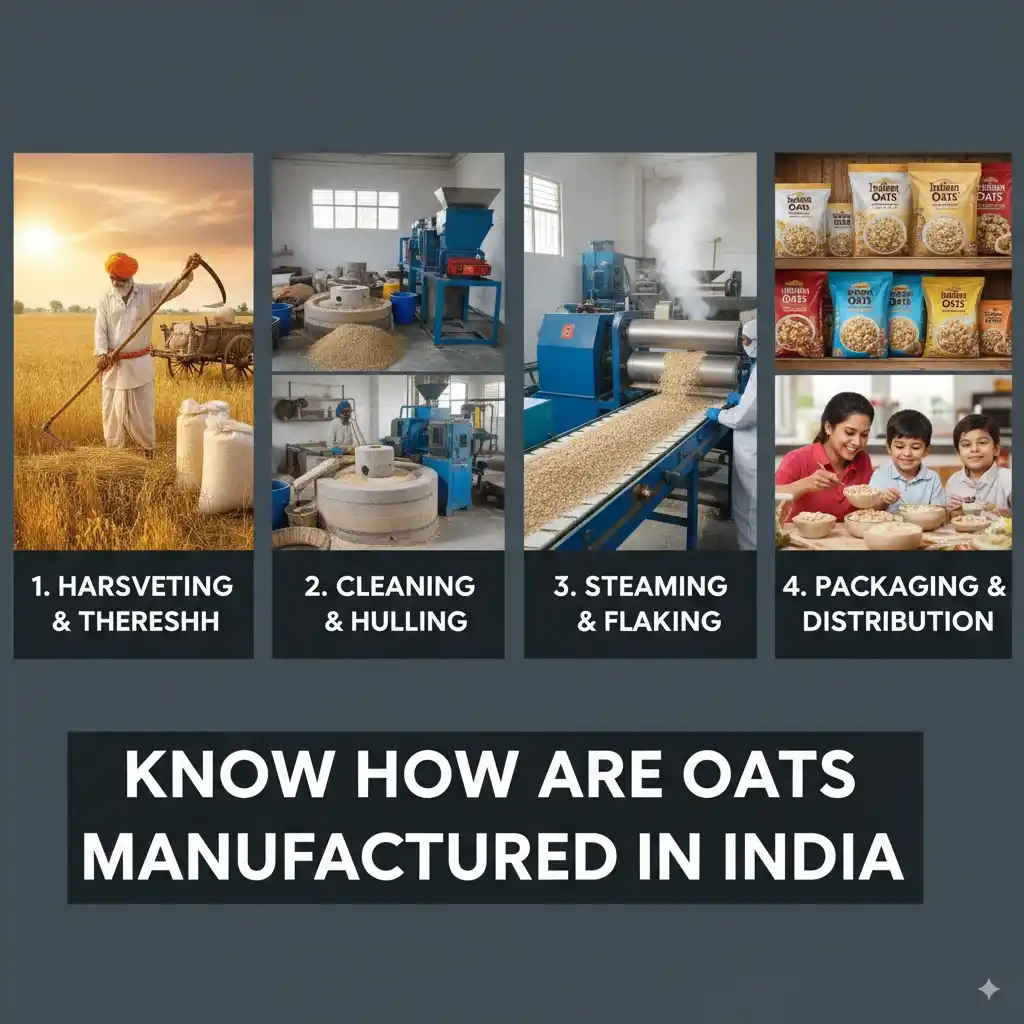

Step 1: Harvesting and Growth Oats

Farmers provide the necessary conditions for the growth of healthy crops and oats to make it productive in colder climatic conditions and farmers usually plant oats in the beginning of spring.

Then farmers will evaluate oat varieties by climate, soil and intended concepts such as oatmeal, oatmeal or feed for livestock.

As the season goes through, oats still mature until they are gold. Farmers then harvest their crops using combined, specialized machines that cut and collect grains when the cores reach the correct level of dryness and maturity.

The next step is the transport of harvested oats to the processing plants. It is in these places that these oats are transformed and made for edible products.

Step 2: Grain cleaning

Once out of the field, the first thing for raw oats should be cleaned. It is during the harvest that oats can pick up dirt, straw, stones or even stray seed from other plants. These impurities may disrupt milling, which then affects the quality of the finished product.

To prevent this, the mills are equipped with various cleaning machines. They use large screens to remove larger residues using powerful air blowers to remove lighter particles such as dust and chaff.

There are magnetic devices mounted to capture all metal fragments raised in the field. Oats are therefore ensured that after this process it will be without undesirable materials.

Step 3: Hulling and separating edible cruel

Hulling is one of the main aspects of oat processing. The hull is a hard, inedible shell surrounding every oat grains. It is therefore at most important to remove the outer torso and expose ourselves as we call ourselves as a groat.

Machines very gently break the torso and at the same time protect the inner grain from any damage. The waste of the fuselage and the semolina is then separated and the hooves are blown.

Interestingly, processors do not lose these hooves; They are commonly converted into animal feed, folded feed or biomass fuel. It is a great way of minimizing waste and stimulating sustainable production.

After exaggerated news, whole oat grains are left, which is rich in protein, fiber and basic vitamins.

Step 4: Heat treatment (steaming, killing).

Untreated natural oils in freshly suppressed grains can spoil very quickly. The heat treatment allows extension of durability and bile prevention.

There are two possible ways to happen:

Kilning: Groats toast at controlled temperatures in great furnaces. It keeps not only oats, but also gives them their walnut smell.

Steaming: Some oats can be briefly steamed instead of being roasted. As a result, they facilitate flakes into flakes.

The heat treatment is one of the most important steps; It seals freshness and kills microorganisms. Oats will enjoy several months of safe storage without deterioration of quality.

Read More: White Oats Processing. Profitable Business Opportunities in Oat Based Products.

Step 5: Rolling or grinding creating different types of oats

They process oats from farmers to your grocery store. The same Groat would create different textures, cooking times and culinary applications using different processing techniques.

Oat oat steel: Stay with whole grains and are cut into chewing small pieces by minimal processing using a sharp steel blade. They’re perfect breakfast.

Old -fashioned oats: Processors start processing by shouting for short steam treatment to soften them. The beans are rolling into flakes with large cylinders. This process shortened the cooking time and created a fine and smooth texture.

Immediate oats: To create immediate oats, the grains are finely cut and steam is treated longer. These oats will cook in a few minutes or even with the most popular hot water-to-day favorite morning.

Oatmeal and oatmeal: Moem Moem Oats is a fine flour that works beautifully in cooking or smoothies. It also separates the outer layer of Groat-folding and sells it as a highly nutritious product.

Adaptation is the focus of this phase. The milling process ensures that there is oats for every taste, whether you prefer your oat chew, cream or smooth.

Step 6: Control of cooling and moisture

After steaming or rolling oats absorbs excess moisture. If they were packed at once, they could clump together or actually spoil.

To avoid this, cooling and drying of oats is required under controlled conditions. Letin currents reduce the moisture content to approximately 10%-12%. This is a safe and long -term storage level.

Read Our Book: Click Here

Step 7: Packaging and Quality checks

Teams for quality control before packaging carefully examine oats. To ensure that each dose is safe, the samples are checked in terms of moisture, taste and consistency.

After approval, the oats are sent by an automated wrapping line. The machines measure the exact amount in bags, canisters or boxes, seal them closely to keep them fresh, and then mark them for transport. Trucks then transport them to supermarkets around the world where you can enjoy.

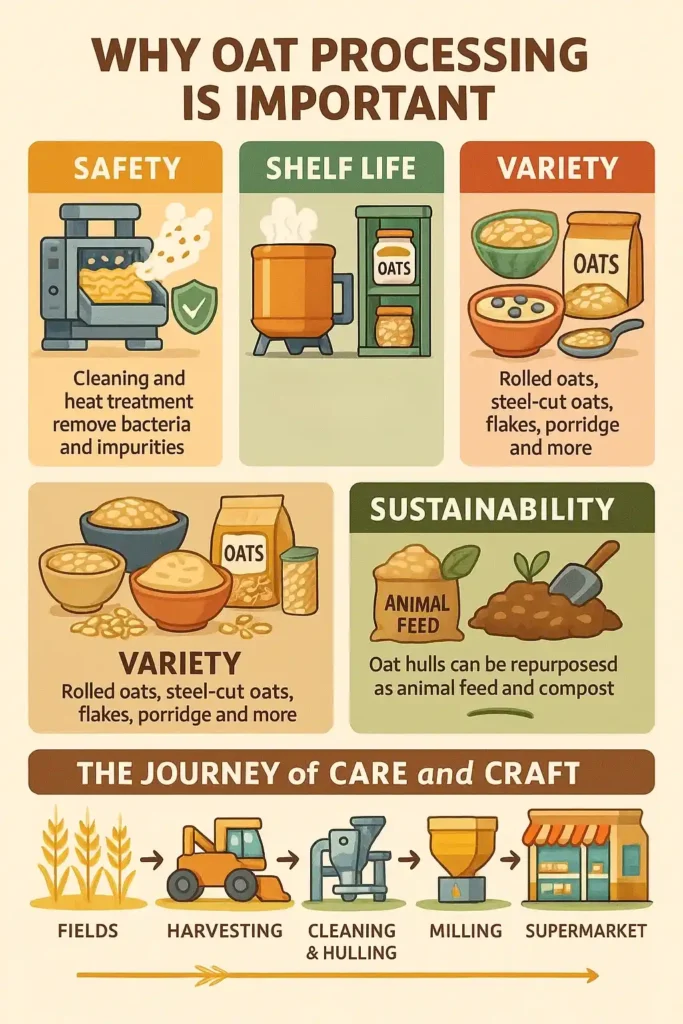

Why is the processing of oats important

Each step in the oat production process has a purpose.

Safety: Heat treatment and cleaning remove bacteria and dirt, which makes oats safe for consumption.

Lifetime: Life: Killing and drying oats can be left in your pantry for several months.

Variety: Different processing methods provide us with different texture and cooking options.

Sustainability: Even waste products such as oatgreals can be reused.

Find the Best Idea for Yourself With our Startup Selector Tool

The way of care and crafts

Oats will take a careful journey from the lush green fields to the local supermarket. Farmers grow them, machines are clean and pipes and mills use demanding techniques to roast, roll them or cut them in a shape we like.

What seems to be a simple breakfast is in fact the result of centuries -old agricultural tradition and modern technology.

Remember that the interesting path of oat oats was mixed into a pot or sprinkled into a smoothie. Oats represents innovation, sustainability and care.

FAQ: All you wanted to know about oats

Q1: Are all integer oat grains?

Yes! No matter what type you choose from steel, laminate or moment, they make the whole oats from the entire oat cries. They maintain their natural fiber, proteins and nutrients.

Q2: Does the immediate oats have less nutrients?

No. Manufacturers roll the best immediate oats and place them for comfort, but maintain almost the same nutritional value as oats or laminated oats. The main differences are texture and taste.

Q3: Can you eat raw oats?

Yes, you can! Like antlers or oatmeal oatmeal during processing, they make them safe to eat. Many people like raw oats in muesli or oats at night.

Q4: What happens to all oat hooks?

Mills redirects oat storage instead of throwing them away. They turn them into animal feeding, garden coverage or biomass energy, reduce waste and support sustainability.

Q5: How long does Oats take after the package?

When you store oats in a cool and dry place, they are fresh for 12 to 24 months. Hermetic packaging protects them from pests and moisture and keeps them to eat.