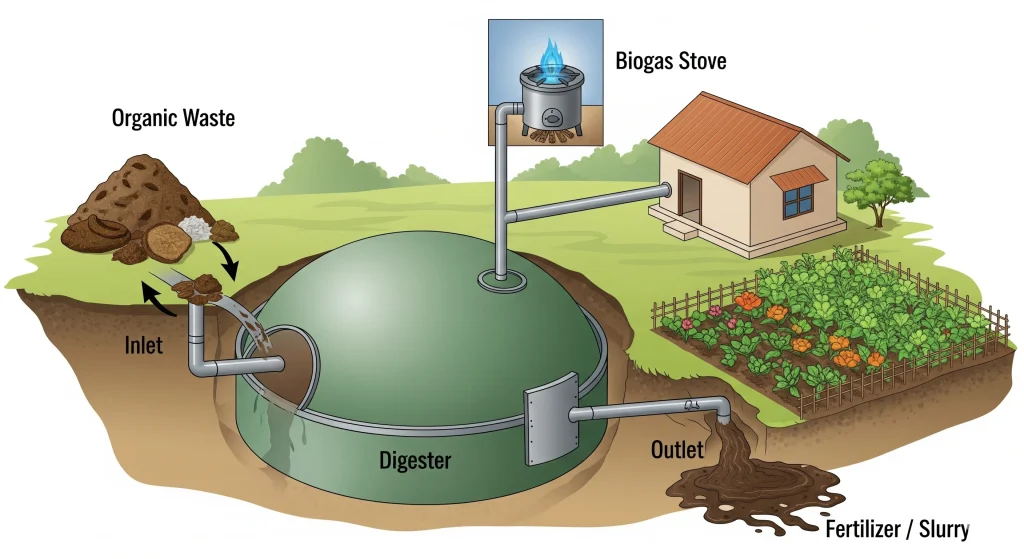

Every day, we create trash. From food scraps from the kitchen and leftover food to manure from the farm and lawn clippings, our garbage accumulates and often ends up in landfills, releasing harmful greenhouse gases. In the meantime, we are paying for electricity and cooking gas, and we consume resources that are limited. What if there were a way to tie the two problems into an elegant and simple solution? It’s known as a biogas plant.

A biogas plant is the perfect way to transform organic matter into safe, cost-free energy and a natural, rich fertilizer. It’s an excellent illustration of nature’s recycling system, which can be found within your backyard. This guide will take you through all the information you need to know about how to begin your biogas plant project. We will discuss the basics of biogas, the process behind it, how it operates, and the great advantages it can bring. In addition, we will give you an easy-to-follow guide on how you can construct one on your own, turning the waste you have accumulated into a fuel source.

What Exactly is Biogas?

At its core, biogas is an energy source that is renewable by organic matter such as human manure, food waste, or agricultural residues — break into pieces in an environment devoid of oxygen. The process that occurs naturally is referred to as anaerobic digestion..

Think of it as the size of a huge mechanical stomach. Like the cow’s stomach digests grass to produce energy, the biogas plant “digests” organic waste. The principal ingredient in biogas includes methane (CH4), the substance that makes up the majority of natural gas that is used to cook and heat our homes. Gas mixtures also have carbon dioxide (CO2) as well as small quantities of other gases. The methane-rich gas is inflammable, which means that you can ignite it to make an uncluttered, constant flame to cook or power a generator.

The basic idea is that a biogas facility is a facility that captures the energy from organic matter that is otherwise wasted, and converts it to an energy source that can be used.

How Does a Biogas Plant Work? A Peek Inside the Digester

Biogas plants may sound complicated, but the procedure that takes place inside is incredibly easy and completely natural. The entire process takes place in the large, airtight vessel known as a digester. digester. In this digester, the trillions of microorganisms (bacteria) start to work, breaking down the waste into four distinct steps.

- Hydrolysis. At the beginning phase, the organic complex molecules found in the waste, such as proteins and carbohydrates, are too large for organisms to “eat.” Thus, one set of bacteria releases enzymes that function like tiny scissors, cutting long chains of these into smaller molecules such as amino acids.

- Acidogenesis. Then, a separate category of bacteria, referred to as acid-forming bacteria, takes over. They consume simple molecules, and then convert them into organic acids, alcohols as well as carbon dioxide.

- Acetogenesis. At the 3rd phase, acetogenic bacteria consume these acids and then produce the acetic acid (the principal component in vinegar) as well as hydrogen and carbon dioxide.

- Methanogenesis is the last and most important phase. Methanogens, or methane-forming bacteria, consume acetic acid and hydrogen. The result of their feast is the ultimate prize: biogas, which is rich in methane.

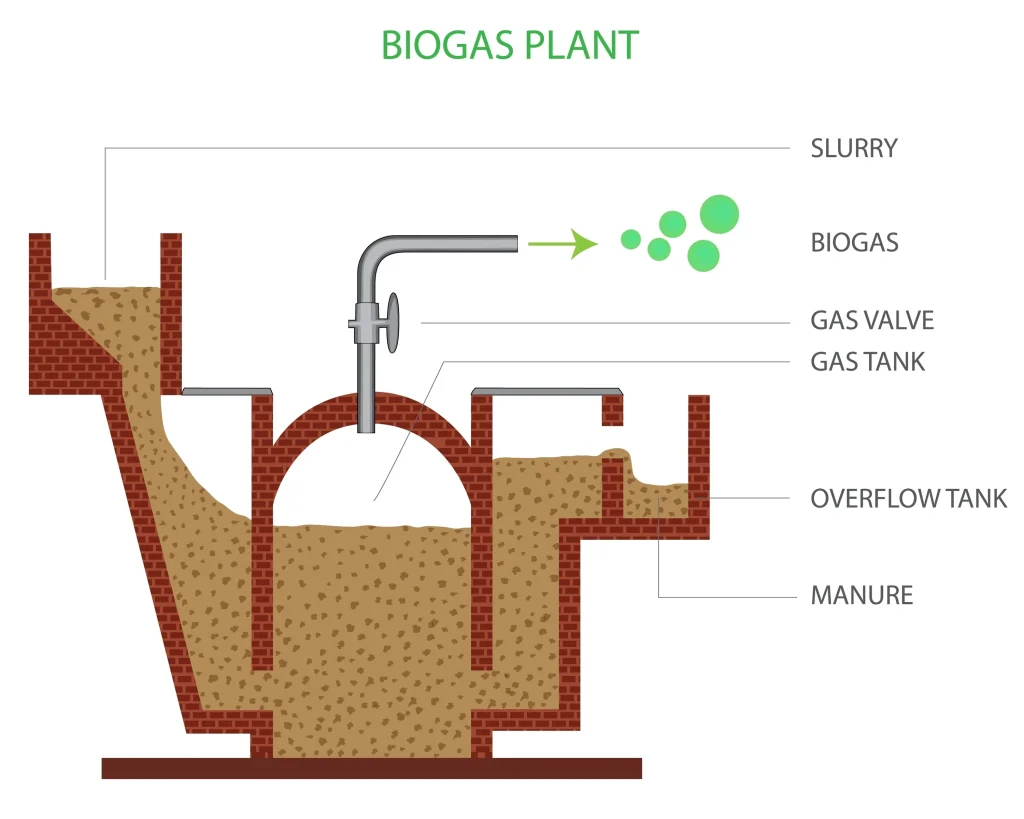

Biogas Plant Project: Key Elements

The most important elements of a biogas plant that can facilitate the process include:

- Mixing Tank, In which you blend organic waste (also known as feedstock) with water to make a Slurry.

- Inlet Pipe It feeds the mix that is mixed in the mixing tank to the digester.

- Digester Tank A main and airtight space where anaerobic digestion takes place. People usually build it underground. That keeps the temperature steady and warm for the bacteria. The gas holder sits at the top. Biogas rises up and collects there.

- Web-based Outlet Pipe: The pipe is a valve that permits you to draw biogas to use in your generator or kitchen.

- Outlet Tank When you put new slurry into the tank the old, digested material (now known as digestate) is released into the tank.

Read Our Book: Handbook on Biogas and Its Applications(from Waste & Renewable Resources with Engineering & Design Concepts)(2nd Revised Edition)

The Gold from Garbage: Outputs of a Biogas Plant

Biogas plant projects are an absolute win-win since they provide you with two useful products that you thought you would throw out.

1. Biogas (Clean Energy)

The main output is obviously biogas. Biogas is a perfect alternative to Liquefied Petroleum Gas (LPG) or natural gas. It is piped directly into a specially-designed biogas stove for your kitchen. A biogas plant that is properly sized for your family produces enough gas for 2 to 4 hours of cooking per day. This eliminates the necessity to buy cooking gas cylinders, thus saving you money while decreasing your carbon footprint. For larger installations, biogas could also be utilized to fuel engines running generators, generating clean electricity.

2. Digestate (Organic Fertilizer)

The other is the slurry, which flows from the digester, also known as digestate. It is an amazing organic fertilizer that is often referred to as “black gold” by farmers. In the process of digestion, bacteria release the nutrients contained in the organic waste and convert them into a form plants are able to easily absorb. The digestate is high in nitrogen, phosphorus, and potassium.

The end product doesn’t stink. The digester kills all the bad stuff and weed seeds. You can use this fertilizer on your garden or fields. Your plants get stronger, and you skip store-bought chemicals.

Read More: Compressed Bio Gas (CBG) Units: Profitable Green Energy Startup Opportunity

Your Biogas Plant Project: A Step-by-Step Overview

A biogas plant construction can be an exciting project. Although larger installations require professionals for engineering, smaller models for the home can be built with local materials and the masonry expertise. Here’s a quick description of the process involved.

Planning and Sizing

The first step is to decide how big your plant must be. This is contingent on two aspects: the amount of waste you’ve got and the amount of gas you require. A general rule of thumb is that dung from three to four cows will generate enough energy to prepare three meals for a household of 4-6. You could also make it up by using kitchen scraps or other organic garbage.

Choosing the Location

Choose a location that is dry, open, and has ample sunshine to maintain the temperature of your digester. It should be located close to the waste source (like the cattle shed) and near the place where you’ll use gas (the kitchen) to reduce the need for piping. It should be at least 10-15 meters from sources of drinking water.

Construction

The most commonly used scale models for small sizes are the Fixed-Dome Plant and the floating-Drum Plant. Construction typically includes:

- Excavation: Excavating a massive pit to accommodate the digestion tank.

- Construction of Masonry: Building the foundation and the walls with a cylindrical shape of the digester using cement and bricks, making sure the digester is totally waterproof.

- Insemination Pipes: Installing inlet pipes and outlets at appropriate levels.

- The Dome/Holder is built: For the fixed-dome type, you build a dome from bricks and cement. The floating drum style uses a steel drum that floats and collects gas.

Preparing the First Feed

It’s not possible to start using the plant straight away It is necessary to provide the bacteria with a boost. It involves making a first mixture with animal waste (cow dung is the best choice because it’s high in methanogens) along with a similar volume of water. The mixture is then put into the digester, which is then filled.

Biogas Manufacturing Plant – Detailed Project Report & Business Plan

Operation and Maintenance

Following the initial filling, it is necessary to wait 2 to 4 weeks to allow the bacteria to grow and begin producing gas. When gas production has stabilized and is stable, you can begin your day-to-day routine:

- Daily Feeding: Combine your day’s amount of waste and water and introduce it into the intake.

- Utilizing the Gas: Open the main valve to allow gas flow through your stove.

- Collecting Fertilizer Digestate is expected to be released from the outlet when you add new Slurry.

Maintenance is not too difficult. All you need to do is check for leaks of gas regularly and make sure that the pipes aren’t blocked.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion: A Powerful Step Towards Sustainability

A biogas plant is much more than a method of managing the waste. You get your own eco-setup at home. Toss in your food scraps and yard waste. This system gives you clean energy and top-notch fertilizer. You cut down pollution and help the planet. Your plants end up healthier, too. It’s an efficient, cost-effective, and efficient technology that transforms the issue of waste into a chance to create a more sustainable, greener future in your backyard.

Biogas Plant Project” Frequently Asked Questions (FAQ)

1. What does an investment in a biogas facility cost?

The price can vary greatly according to the dimensions, model and the local costs for materials. A small plant for families constructed with cement and bricks will cost anything between Rs20,000 and Rs50,000 in India. The government offers subsidies across the world that can drastically reduce the price.

2. Does a biogas facility smell bad?

Not at all. A functioning biogas plant is an airtight structure and virtually odorless. The slurry that is digested (digestate), which is produced is free of the unpleasant smell that is typically found in manure from raw sources.

3. What should I include in my biogas plant?

The most suitable source of feedstock is manure from animals, specifically from pigs and cows. It is also possible to include food waste (vegetable peels, leftover food items) and agricultural residues, as well as human waste. Avoid putting in woody material (like branches) as well as plastics and chemical detergents, as they may interfere with digestion.

4. Is the biogas created safe to use?

It is completely safe for cooking. Similar to LPG and LPG, biogas is highly flammable. Therefore, you should make sure you use the right fittings and pipes, and look for leaks frequently. Since it’s a mixture of contaminants, it is recommended to utilize a stove specially designed to work with biogas for maximum efficiency and security.

5. What is the length of time a biogas plant runs?

If it is constructed properly, a brick (brick as well as cement) biogas plant is able to last between 20 and 30 years or more with very little maintenance. The gas holder made of steel for a floating drum model could require re-painting every couple of years to avoid corrosion, but is very robust.