Alum is a grouping of chemical compounds that have strong astringent properties and coagulating abilities. It plays a significant role in a variety of industries, from paper and cosmetics to water purification. The product’s versatility, relative simplicity of production, and steady market demand make it an attractive option for entrepreneurs looking to break into the chemical manufacturing industry. Alum manufacturing is a lucrative business for startups in the small and medium industrial sector.

This detailed guide will examine the market outlook for the industry, the demand drivers, the manufacturing process, and the important considerations to start a successful alum production venture.

Understanding Alum’s Industrial Importance

Alum is a group of double salts that contain aluminium sulfate, and the sulfate from another metal such as ammonium or potassium. The most common form of potassium alum, KAl(SO4)2*12H2O, is used to treat water to remove impurities. It’s also widely used to improve paper sizing and to add astringency to cosmetic products.

Alum is used in water treatment as a coagulant. It binds small particles together to form larger aggregates. This makes it easier to purify and filter water. It is used as a mordant in the textile industry to fix dyes on fabrics. It is used in the food industry for pickling, baking powder, and traditional medicine. The wide range of applications ensures a stable market across many industries.

For more information, check our Handbooks

Market Outlook for Alum Manufacturing

In the coming years, it is expected that the alum industry will grow steadily, thanks to urbanization, water treatment requirements, and growth in the paper and cosmetics industries. This demand is further fueled by the industrial growth of emerging economies and stricter environmental regulations regarding water quality.

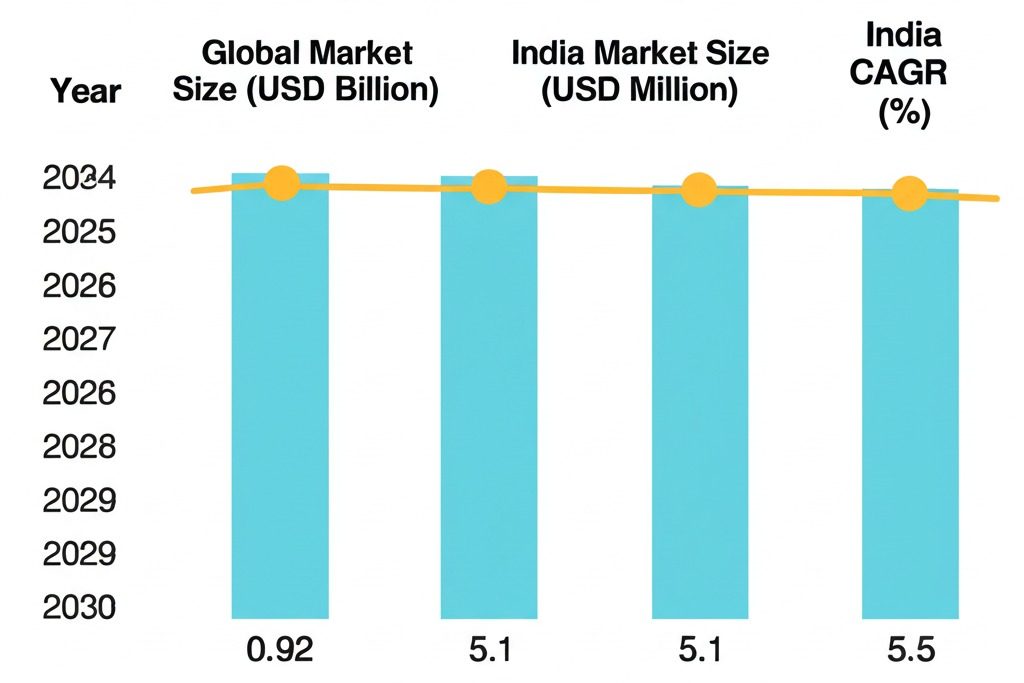

Global and India Alum Market Forecast (2024-2030).

| Year | Global Market Size in USD Billion | Global CAGR (%) | India Market Size in USD Millions | India CAGR (%) |

| 2024 | 0.92 | — | 145 | — |

| 2025 | 0.97 | 5.1 | 153 | 5.5 |

| 2026 | 1.02 | 5.1 | 162 | 5.5 |

| 2027 | 1.08 | 5.1 | 171 | 5.5 |

| 2028 | 1.13 | 5.1 | 181 | 5.5 |

| 2029 | 1.19 | 5.1 | 191 | 5.5 |

| 2030 | 1.25 | 5.1 | 202 | 5.5 |

Market Data: Insights

The alum industry will grow at a CAGR just above 5% globally, but India’s growth is slightly higher than the average, due to the rapid development of infrastructure, municipal water treatment projects and the growth in the paper and cosmetic industries. Alum manufacturing is a long-term, reliable industrial venture because of its stable growth pattern.

Related: How to Start an Aluminium Phosphide Manufacturing Business?

Key Demand Drivers

Multiple industrial and environmental factors support the demand for alum. Water treatment facilities are being built by governments and private companies due to the growing concern over waterborne illnesses and the need for safe drinking water. Alum is a popular coagulant because of its effectiveness, affordability, and ease of availability.

Despite global digitization trends, the paper industry continues to grow in emerging markets, despite its use of alum for paper quality and printability. The cosmetics industry has seen a surge in the use of alum-based skin care and deodorants due to the growing demand for chemical-free and natural personal care products.

Textiles still use alum as a mordant. This is especially true in countries like India, Bangladesh and Vietnam, which have large hubs of fabric production. Food processing, though smaller than the water and paper industries, is a niche consumer.

Manufacturing Process of Alum

Alum can be produced using readily available materials like bauxite or cryolite. You will also need sulfuric acid. The basic steps are the same, regardless of the market and the equipment used.

1. Raw Material Preparation

The first step is to select and prepare raw materials containing aluminium. In most cases, bauxite ore can be used. However, in some cases, aluminium scrap is also an option to make the process more sustainable. The material is crushed to the desired particle size and then ground for efficient reaction with sulfuric acids.

2. Reaction with Sulfuric Acid

In reaction tanks, the powdered material is mixed with sulfuric acid. This chemical reaction creates aluminium sulfate which is used as the base compound in alum production. This reaction is usually exothermic, and temperature control is required to maintain consistency.

3. Purification and Filtration

Filtering is done to remove impurities like silica and iron compounds. This step is crucial for industries such as water treatment and cosmetics, where high purity levels are required.

4. Crystallization

The addition of potassium sulfate or ammonium sulfate to the purified aluminium solution (for potassium alkali) will result in the formation of alum crystals. Under controlled conditions, the mixture is allowed to crystallize into alum crystals.

5. Drying and packaging

Crystals are separated from liquids, cleaned to remove adhering impurities and dried on rotary or tray-style dryers. The alum can be packaged into bags or containers depending on the customer’s requirements and intended application.

Related: How to Set Up a Profitable Potassium Hydroxide Manufacturing Unit

Quality Standards and Compliance

Manufacturers must adhere to strict quality standards to ensure that alum meets the industrial and public health needs. The Bureau of Indian Standards specifies parameters in India, such as particle size and allowed limits for heavy metals. Compliance with ISO standards or country-specific regulations is crucial for export markets.

In addition, it is important to adhere to environmental standards for waste disposal, as well as the proper labeling and safety data sheets.

Alum Manufacturing: Challenges and Opportunities

Alum production is a stable industry, but it has its challenges. The fluctuations in raw material prices, particularly for bauxite or sulfuric acid, can affect profitability. The environmental regulations governing chemical handling and waste disposal have become stricter. This requires investments in effluent systems.

Market dynamics may be affected by competition from other water treatment chemicals such as polyaluminium (PAC). The cost-effectiveness of alum and its multi-industry application continue to make it relevant.

Sustainability is a key concern

Modern alum production is becoming more eco-friendly. Aluminium scrap is now used as raw material in many plants, which reduces the environmental impact. Water systems with closed loops and energy-efficient crystallization methods are also being used. Waste byproducts can also be used in other industries to reduce disposal costs and impact on the environment.

For more information, check out this related video

Future Trends and Opportunities

Alum is expected to gain from the increasing investment in municipal water infrastructure, particularly in developing economies. Alum of high purity will also find new markets as the popularity of natural products for personal care grows. There are niche applications such as the pharmaceutical-grade alum used for dental and medical purposes.

The use of advanced technologies in packaging, quality control and process automation can improve the operational efficiency for smaller manufacturers, allowing them to compete with large players.

Find Best Idea for Yourself With our Startup Selector Tool

The conclusion of the article is:

Entrepreneurs who are willing to invest in high-quality production, market knowledge, and compliance with safety and environmental standards can start an alum business that is profitable and stable. Small and medium enterprises are attracted to the industry because of its steady growth, broad application range, and relatively simple manufacturing process.

Niir Project Consultancy Services prepares detailed techno-economic feasibility reports, including the manufacturing process, raw material, plant layout and financials. NPCS assists entrepreneurs in assessing the feasibility of starting new businesses or industries, ensuring that they make informed decisions at each step.

New entrants to this sector can build a strong position by focusing on quality, diversification of markets, and sustainable practices.