In today’s competitive business environment, entrepreneurs have to be innovative and creative to succeed. Establishing your production unit of adhesive (Fevicol Type) can be beneficial if you are new to the market or currently employed in this industry and wish to start your own business venture on the side.

Like starting any other business, you need to consider several key aspects before making final decisions about opening your own production business.

Set Up Production Unit of ADHESIVE (Fevicol Type)

An adhesive is any substance that you apply to one surface (the substrate) to create an attraction between it and another surface. Generally, since most adhesives are polymeric, mechanical methods such as molecular bonding (e.g., covalent bonding) hold them together.

Moreover, by enhancing interfacial shear strength, additives (for example, plasticizers) can significantly improve binding. In addition, these additives help to optimize the adhesive’s performance under various conditions. Therefore, understanding both the chemical and mechanical aspects is crucial for developing effective adhesives.

Related: Most Profitable Small-scale Manufacturing Business Ideas for Indian Startups

Uses:

- Carpenters use a variety of adhesives to complete their work. Vinyl acetate is used to manufacture Yellow Wood Glue, which is commonly water-based.

- People use adhesives such as white craft glue for lightweight materials like cardboard, paper, cloth, and children’s crafts. Because water often carries them, they are easier to clean and less harmful. These glues must cure before you can determine their strength.

Business Plan: Set Up Production Unit of ADHESIVE (Fevicol Type)

Market Size in India:

Expansion of several end-user sectors, India’s adhesives industry has developed to become one of the world’s largest users of adhesives. Experts expect India’s adhesives business to reach a value of USD 5.7 billion by the end of 2020. Furthermore, the United Nations predicts that India’s urban population will increase by 57 percent from 377 million in 2011 to 594 million in 2036.

Related Feasibility Study Reports: Adhesives and Sealants, Industrial Adhesives, Glues, Gums & Binders, Synthetic Resin, Resins (Guar Gum, Adhesive [Fevicol Type], Sodium Silicate Adhesive, Hot Melt Adhesives, Rubber Based Adhesive, Acrylic Adhesives, Guar Gum Powder, Gum Arabic)

Global Market :

Growth in the packaging, building & woodworking, and transportation end-use industries, as well as technological advancements, have assisted the evolution of the industrial adhesives market. The industrial adhesives market grew at a CAGR of 4.8 percent between 2015 and 2021.

Watch other Informative Videos: Adhesives and Sealants, Industrial Adhesives, Glues, Gums and Binders, Synthetic Resin, Resins (Guar Gum, Adhesive [Fevicol Type], Hot Melt Adhesives)

Dental Care Products, GI Cement & Composite Lite Cure Business Plan

“Glass Ionomer Cement.” Manufacturers make it from acrylic resin, water, and a glass filler (glass ionomer) that hardens via an acid–base reaction. Dentists place the tooth-colored filling on top of exposed root surfaces as well as cavities after removing decayed or damaged tooth structure.

Dentists apply restorative materials such as porcelain veneers, crowns, and tooth fillings on top of the cement. Furthermore, employing a glass ionomer cement makes installing composite fillings easier than using traditional amalgam fillings.

Advantages:

A systematic evaluation showed that when dentists used GICs as a fissure sealing material, they found no difference in caries formation compared to traditional resin-based sealants. Additionally, the fissures remained more resistant to demineralization even after visible loss of sealant material. Furthermore, it has poorer dental structure retention than resin-based sealants.

For new business ideas, visit

Market Outlook:

Experts predict that the global Glass-ionomer Cement market will grow at a CAGR of 4.5 percent from 2021 to 2027, increasing from USD 118.4 million in 2016 to USD 154.1 million in 2027.

The main drivers of this growth are rising disposable income levels, increased awareness of dental care, and increased demand for dentistry services in developing countries such as China and India, owing to economic development, favourable government initiatives, and improvements in healthcare infrastructure, as well as rising disposable income levels.

India Dental Devices Market

Experts estimate that the India Dental Devices market will increase at a CAGR of 6.5 percent over the forecast period (2022-2027). The number of dental implants and oral surgeries performed has increased as a result of the rise in oral issues, notably among youngsters and the elderly.

Related Article: Top 10 Profitable Poultry Business Ideas For Rural Startups

Benzoic Acid/Sodium Benzoate Manufacturing Business

The organic compound benzoic acid, also known as sodium benzoate or benzene carboxylic acid, has the formula C7H6O2. Benzoic acids and a number of other chemical compounds, like benzoin resin, include it. Because of its fungicidal, antibacterial, and antifungal properties, benzoic acid was once used in toothpaste and deodorant.

Applications:

Benzoic Acid

- The manufacture of phenol requires the use of benzoic acid. Benzoic acid ointments are used to prevent or cure fungal skin infections.

Sodium Benzoate

Manufacturers have used sodium benzoate in a variety of items because of its antimicrobial and flavoring characteristics. It serves as the most widely used food preservative worldwide and appears in both food and soft drink products. You can find it in margarine, salsas, maple syrups, pickles, preserves, jams, and jellies.

Market Outlook:

Experts anticipate that the Benzoic Acid Market will reach \$2.4 billion by 2025, rising at a CAGR of 9.5 percent from 2020 to 2025.

Rising demand for food preservatives in China and India drives growth in the benzoic acid market segment of the end-use food & beverage industry. Experts expect the Sodium Benzoate Market to grow at a CAGR of 4.3 percent from 2021 to 2028.

Start Production Business of Tartaric Acid

You can find tartaric acid in a range of fruits and vegetables, including bananas, grapes, citrus, and tamarinds. Racemic acid or 2, 3-dihydroxyl succinic acid are other names for it. It is used in the carbon dioxide manufacturing process. It’s a diprotic crystalline white diprotic aldaric acid. In the pharmaceutical industry.

Uses:

- To improve the flavour of oral medications.

- Metal ions such as calcium and magnesium are chelated.

- Used in recipes as a leavening agent in conjunction with baking soda.

- It has anti-oxidant properties.

- Acidity is a major component in wine.

Tartaric Acid Market in India:

Experts predict the Indian tartaric acid market will grow rapidly over the forecast period. The market’s growth stems from the increasing use of tartaric acid as a preservative in packaged goods and its expanding applications across various end-user sectors such as food & beverages and pharmaceuticals.

The proliferation of cosmetics, personal care, and male grooming products, along with improved awareness of skincare, body care, and hair care, is also driving the growth of the Indian tartaric acid market.

Market Outlook:

Experts expect the global tartaric acid market to be worth \$2.55 billion in 2020. They estimate the market will grow at a CAGR of around 6.4 percent between 2021 and 2030.

The food industry is one of the world’s fastest-growing businesses, providing opportunities for newcomers. Only a few manufacturers and established organizations are focusing on boosting production capacity in the tartaric acid market, which is a consolidated market.

Citric Acid Production Business Plan

Citric acid, a naturally occurring organic molecule, gives citrus fruits their sour flavour. Industries use it in a variety of industrial applications, making it an important component across sectors such as food and beverage production, personal care products, and chemical manufacturing.

Uses:

It can be extracted from citrus fruits like lemons, limes, and oranges. It’s used to keep food fresh and add flavour to a variety of dishes. Cosmetics and cleaning goods also include it. It’s utilized as an acidity regulator or firming agent in soft drinks, jams, jellies, sweets, and a range of other foods.

India Citric Acid Market :

By 2020, India’s citric acid market will reach 80,800 metric tonnes, and it will grow at a CAGR of 5.7 percent between 2021 and 2026

India’s market is mostly driven by the country’s burgeoning pharmaceutical industry. Furthermore, a number of major companies across the country are exploring mergers and acquisitions (M&A) to take advantage of the market’s abundant expansion opportunities.

Global Market Outlook:

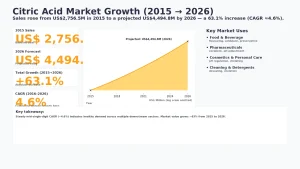

Sales of citric acid totaled US$2,756.5 million in 2015 and are predicted to reach US$4,494.8 million by 2026. Sales revenue is predicted to expand at a CAGR of 4.6 percent over the forecast period (2016–2026).

Experts estimate that the market will increase in volume at a CAGR of 3.7 percent over the forecast period. Citric acid demand is rising all across the world as a result of this.

Sorbic Acid/Potassium Sorbate Production Business

Sorbic acid, potassium sorbate, and derivatives serve various uses in the cosmetic and pharmaceutical industries. By limiting the growth of bacteria, mould, and yeast, these chemicals work as preservatives in a number of products, including shampoo, cosmetics, and lotions. Manufacturers use them to produce anti-corrosive solutions and to create household or industrial items like metal polishes and wood floor cleaners.

Uses:

Manufacturers mostly utilize sorbic acid as a food preservative. The FDA has approved it as a food additive to prevent the growth of bacteria, mold, and yeast.

There are several advantages of using sorbic acid in your product. Firstly, it improves flavour and additionally acts as an antioxidant. Moreover, it increases shelf life and, importantly, does not affect colour or aroma. Furthermore, it does not react with other ingredients, is also heat stable, and consequently, does not create gas at high temperatures. Finally, it is biodegradable, making it an environmentally friendly choice.

Market perspective:-

Sorbic Acid Market

The global Sorbic acid market will increase at a CAGR of 4.7 percent between 2020 and 2030, from $347,661.0 thousand in 2019. Largely to blame is the presence of well-established food and beverage and pharmaceutical firms in Western economies, as well as increased per capita food and beverage consumption in emerging economies like India, China, and Brazil.

Potassium Sorbate Market:

The market value of potassium sorbate was $154.7 million in 2019, and analysts predict it will grow at a CAGR of 4.89 percent from 2020 to 2025. Sorbate of potassium its broad use as a preservative in food goods, as well as the fact that it is widely available and inexpensive, has fueled market expansion.

Related Article: Top 6 Dairy Business Ideas For the Market Today

Frequently Asked Questions

- What is a “Fevicol type” adhesive?

It generally refers to water-based polymer adhesives (commonly PVAc—polyvinyl acetate—emulsions) used for woodworking, general bonding, and household uses. These are non-solvent, easy to handle, and widely used in carpentry and crafts. - Who are the main end-users?

Carpenters and furniture makers, packaging manufacturers, construction/woodworking shops, stationery and craft markets, retailers, and some small industrial OEMs. - What are the typical raw materials?

Polymer emulsion (PVAc or similar), water, plasticizers, thickeners, stabilizers/preservatives, fillers (e.g., talc), crosslinkers or co-polymers (if required), and performance additives (wetting agents, defoamers). - How do additives affect adhesive performance?

Additives such as plasticizers and crosslinkers improve flexibility, interfacial shear strength, cure behavior, and resistance to environmental stresses, which enhances overall bonding performance. - What basic equipment is needed for a small production unit?

Emulsion blending tanks with stirrers, dosing pumps, homogenizers or high-shear mixers (depending on formulation), storage tanks, filler dosing systems, filtration, filling and packaging lines, and basic QC lab instruments.