There are lots of opportunities and entrepreneurship in industrial manufacturing. Specifically, the chemical and energy sectors are ripe for investment.

However, with appropriate details and the appropriate strategy, business potential customers can uncover success with the support of companies like NPCS. In this comprehensive article, you will learn about three different yet identical profitable industrial-businesses for you.

Read Our Book: Click Here

LPG Bottling Plant: Powering Contemporary Lifestyles

Liquefied Petroleum Gas (LPG) is an indispensable and versatile source of energy, commonly used in kitchens, hotels and industries.

Due to its cleanliness and high efficiency, it has been the preferred alternative fuel for many countries. In this chain, an LPG bottling plant plays a very important role to ensure that gas is under proper condition. So, there is a significant growth opportunity for this business.

Market Outlook & A BIG OPPORTUNITY

The global liquefied petroleum gas (LPG) market is booming. We appreciate the Global Liquefied Petroleum Gas (LPG) Market at $121.1 billion in 2022. We can expect it to reach $163.14 billion by 2031. It shows a Compound Annual Growth Rate (CAGR) of 3.8% from 2024-2031.

Actually, the LPG gas cylinder industry will growth from 2024 by USD 8,582.77 million to USD 16,242.5 million by 2032, at 8.2% CAGR between 2024 and 2032.

But the best number for a new founder is in a massive structural hole. India has experienced a booming growth of approximately 58% in LPG consumption since FY 2015.

It shows a great deal of under-capacity, which indicates an immediate and unseasoned demand for new bottling plants. Now, the space left here is highly oft where new players can enter the arena.

The IMARC Group even estimates that by 2033 the LPG bottling plant market alone will be worth USD 956.0 million, indicating a bright future for the industry.

Read More: How to Start a Contract Manufacturing Business in Agrochemicals

The LPG Bottling Process

An LPG bottling plant is not a plant where LPG is produced. It is a location where LPG is transferred into cylinders nicely in a suitable way for people to use.

The plant receives bulk LPG, which is a mixture of commercial propane and butane, and performs a high precision filling operation in compliance with safety standards. This process is known to have multiple steps key to the process:

Receiving and Storage: At the plant, bulk LPG arrives by tankers, and it is safely transferred into large, high-pressure storage vessels.

Empty cylinders are subject to a series of checks: Visual checking for damage, washing, and drying.

Purge and Fill: One of the reasons operators purge the cylinders of residual air before filling is to remove any contaminants that could compromise purity and safety.

The final, most important phase is loading cylinders onto computer controlled carousels where they are filled with LPG by weight—not volume—so as to be as accurate as possible.

Quality Control: Workers inspect the valves for leaks and attach safety caps after filling. Leak Detection Tests are one of the Quality Checks, and each filled cylinder undergoes these tests prior to dispatch.

Investment and Strategic Considerations

Starting an LPG bottling plant needs a huge capital investment. The most significant expenditures consist of land, huge storage vessels, automatic filling equipment, safety systems, and a logistics fleet. But the need for it is high and it is a necessity therefore the investment returns can also be high and steady.

Entrepreneurs need to fill the gap and target rural and semi-urban areas with basic LPG access still being built, to innovate and address these needs. In addition, targeting more niche commercial markets (e.g., hotels, industrial clients) can yield supplementary revenue.

The sector has serious regulatory challenges and is exposed to price cycles, but the right business plan emphasizing safety, low-cost operation and location can mitigate those issues and create a really high margin business.

The Power of Sodium Hydrosulphite as a Reducing Agent

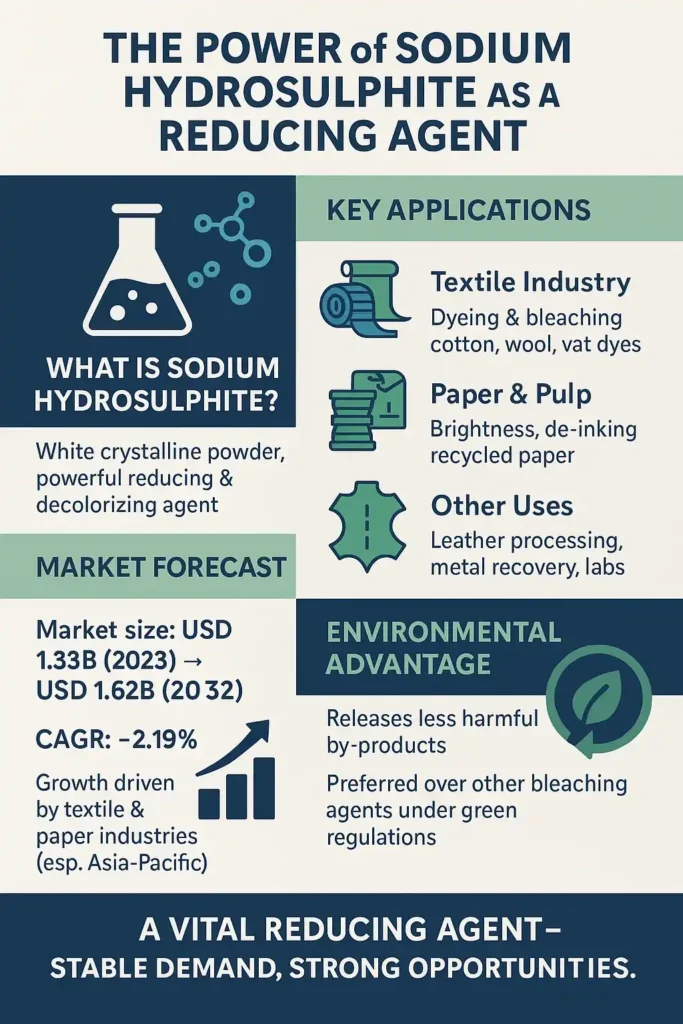

Sodium Dithionite ((Na₂S₂O₄)) is an essential and indispensable reducing agent widely used in several industrial processes. Due to its decolorizing and reducing property, it is an important industrial input for textile, paper and pulp, and photography industries.

Manufacturing Sodium Hydrosulphite can be a potential business opportunity for entrepreneurs to supply a wide range of industrial clientele with a useful and in-demand chemical.

Market Forecast and Demand Drivers

The Sodium Hydrosulphite market is showing stable and continuous growth across the globe.

In 2023, we estimated the size of the market at around USD 1.33 billion and as per our projections, the market will grow over USD 1.62 billion by 2032. We can expect it to grow with a CAGR of around 2.19% during the forecast period.

Though this growth seems slow, the absolute number of industrial applications means demand will always remain stable and strong.

This market is majorly driven by the continuous growth of the textile industry, particularly in the Asia-Pacific region, where it is used extensively for dyeing and bleaching processes. In the same way the paper and pulp industry use it to bleach pulp and de-ink recycled paper.

Furthermore, rising environmental regulations are forcing the industries to move toward more environment friendly bleaching agents, which is provides Sodium Hydrosulphite additional advantage as it releases less harmful by-products.

Properties, Applications, and Manufacturing

Sodium Hydrosulphite is a white crystalline powder; an effective reducing agent. Its primary applications include:

- Textile: Important dispersing agent for vat dyes as well as sulphur dyes, and for bleaching cotton and wool.

- Paper and Pulp Industry: For bleaching pulp and enhancing the brightness of paper products

- Other application: It is used as leather processing, metal recovery, and laboratory reagent.

Sodium Hydrosulphite is usually manufactured by its precursors through chemical responses such as Sulfur Dioxide (SO₂), Caustic Soda (NaOH), and Sodium Sulphide (Na₂S). It is a carefully regulated process in which variables such as temperature, pressure and pH must be kept in ranges that assure a high-purity product which is then dried and packed for use in Industry.

Read More: Chemical Products in High Global Demand with Local Production Potential

Bleaching Powder: A Mainstay of Sanitation and Industry

Bleaching powder (Calcium Hypochlorite) is a strong disinfectant and oxidizing agent (Ca(ClO)2), used in many applications. Because of its use in the purification of water, sanitation and as an industrial bleaching agent, this chemical is always going to be in demand.

Bleaching Powder Manufacturing Unit finds a niche in public health and industrial needs to become an evergreen and growing market for entrepreneurs.

Market Forecast and Growth Factors

Bleaching powder market is growing consistently all over the globe. The global bleaching agents market is a better match for this product, which had a market value of USD 887.7 million in 2022 and is forecasted to reach USD 1,350.1 million by 2030, registering a CAGR of 5.4%.

In fact, we estimate the bleach powder market size to be USD 1.5 billion in 2024, and is expected to grow USD 2.3 billion by 2033 at a rocking CAGR of 5.2%

Such demand is primarily driven by rising hygiene consciousness, growing urbanization resulting in improved water treatment plants, and government sanitation programs initiated.

The significant use of it in textile industry for its use in bleaching fabric, use of it in food industry as a disinfectant assures its position in the market making it a steadfast investment option.

Applications and Manufacturing Process

Bleaching powder is a white granular powder that works by releasing chlorine, which is a very effective microorganism killer and compound coloring agent. Its diverse applications include:

Water Purification: Used in disinfecting drinking water, swimming pools, and wastewater.

Sanitation: For primary disinfection, used in hospitals, in public facilities and in households.

Textile Industry: Bleaching of natural fibers such as cotton and linen.

Food Process: Sanitation of the material and area to ensure cleaning.

Production process is a reaction of chlorine gas with dry slaked lime (calcium hydroxide – Ca(OH)2). It is prepared by makers from limestone and from chlorine gas (mostly, produced by electrolysis of brine (sodium chloride solution)). It necessitates the use of chlorine and stringent control over reaction conditions to ensure the quality and stability of the latter.

Read Our Project Report: Click Here

How NPCS Can Assist You in Your Business?

Niir Project Consultancy Services (NPCS) is a reliable name in the industrial world for offering integrated technical consultancy services. From analyzing the market to identifying plant site, NPCS writes detailed business plans and project reports tailored to your business mode of operation.

They provide services such as feasibility studies, market surveys, technical know-how, financial analysis etc. These support entrepreneurs to take confident decisions.

Being more than 30 years in the same domain NPCS provides viable, off-the-shelf solutions to make rapidly expanding Indian markets comprehensible. If you are looking for an industrial plan of a new business or if you want to scale-up your current system, NPCS can help with its best consulting and technical resource support.

Find the Best Idea for Yourself With our Startup Selector Tool

High-Demand Businesses: Conclusion

The industrial scene offers much to opportunists, people who want to invest in the necessary areas. The three focus areas – LPG Bottling, manufacturing of Sodium Hydrosulphite and production of Bleaching Powder – hold a distinct appeal for an investor.

LPG bottling is a high energy infrastructure shortfall with huge growth opportunities. Sodium Hydrosulphite manufacture serves the basic needs of flourishing industries. Production of Bleaching Powder fulfils the requirements such as public health, sanitation and industrial hygiene.

Both of these ventures provide a route to creating a commercial and sustainable venture. The route to industrial success is straightforward, and with the correct data, strategy and expert help it’s absolutely achievable. For more assistance, contact us.

High-Demand Businesses: Frequently Asked Questions

Q1. What is currently the biggest opportunity in the LPG bottling market?

The primary opportunity is in the wide divergence between fast-growing LPG demand (58% higher than in 2015) and much slow growth in bottling plant capacity (just 12%). This lack of capacity means that there is a great need for more bottling plants.

Q2. What are the industries having the most consumption of Sodium Hydrosulphite?

The textile and pulp and paper industries uses the most (for example for dyeing and bleaching for textiles, as well as the use of chlorine dioxide in pulp bleaching and to de-ink recycled paper), thus ensuring a steady demand.

Q3. What are the key factors driving Bleaching Powder Market?

Growth depends on rising hygiene awareness, fast urbanization demanding improved water treatment and government programs concentrating on sanitation as well as clean water.

Q4. Why are these three businesses good ideas for new entrepreneurs?

All three make a foray into basic needs that are not cyclical — energy (LPG), industrial manufacturing (Sodium Hydrosulphite) and public health/hygiene (Bleaching Powder). This is how you construct stable, nameable markets with clear demand.

Q5. How can NPCS feasibility report assist an entrepreneur start their own entrepreneurship?

A full such business blue print is available in NPCS report. It provides information such as manufacturing requirements, plant configuration, raw material required, including a detailed financial analysis.