Think back to when you received an item from Flipkart or Amazon online stores. Definitely your attention might have been drawn solely to what was in there. But there is a container also deserves recognition as part of an industry which plays an essential role.

They ensures everything from fresh mangoes and medicines to brand new mobile phones and televisions reach you safely from factory. Yes, we are talking about Corrugated Industry.

Corrugated packaging industry goes well beyond making cardboard boxes. It is an engineering marvel that creates strong yet lightweight and sustainable solutions to modern packaging problems.

India is experiencing rapid economic development; corrugated industry plays an integral part of manufacturing, logistics and e-commerce industries alike. In this guide we take you inside this fascinating sector; explaining its role and opportunities available within India itself today.

Corrugated Box Anatomy: More Than Paper

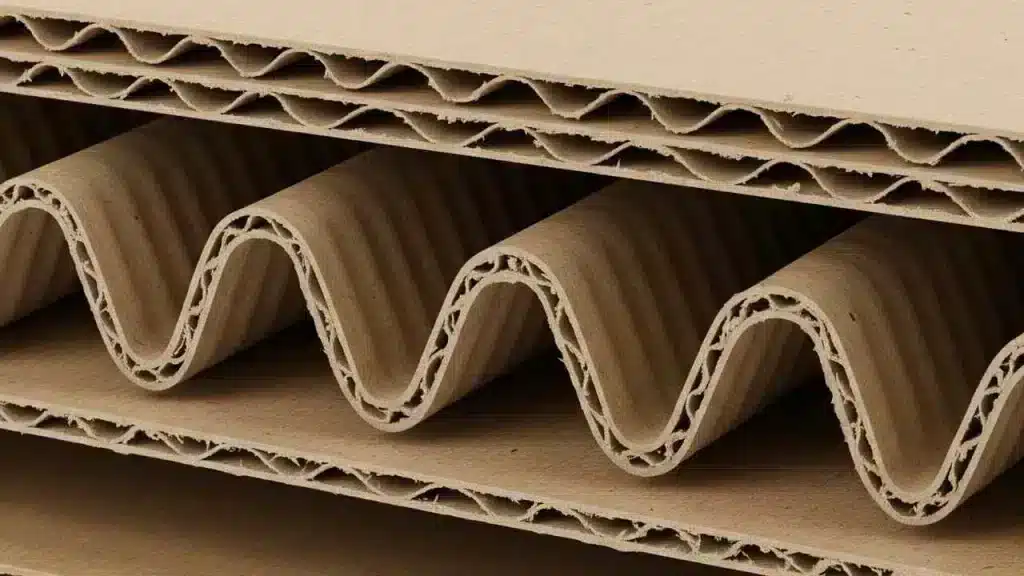

At first glance, corrugated boxes may look similar to conventional cardboard packaging. But their strength comes from being constructed of three separate layers that act together for greater strength.

Liners: Each box features two flat outer paper layers referred to as liners. An inside liner and an outside liner. It provides printing ease as well as shape to its basic framework.

The Medium: Sitting between these two liners lies one of its most vital parts – an uneven layer of paper known as fluted medium.

Corrugated boards’ charm lies in their flutes. Like bridge arches, these flutes create interconnected arches which serve to cushion bumps and impacts while providing rigidity and stacking strength to warehouses so boxes can be stacked higher without crushing their contents at the bottom.

Corrugated board manufacturers recycle many layers from recycled paper making the industry highly sustainable.

Related Article: How to Start a Corrugated Box Business in India: Step-by-Step Guide

From Paper Roll to Packed Box: The Manufacturing Journey

Manufacturers use sophisticated machinery to transform giant rolls of paper into the packed boxes we use every day. Each step must be executed precisely, which requires constant precision from their team of manufacturers.

Step 1: Corrugation [Corrugating]

Our journey starts in a large machine called a corrugator. It feeds a massive roll of paper (the medium) between two large heated metal rollers with gear-like surfaces which use heat and pressure to bend it into its signature S-shaped flute pattern.

Step 2: Adhesive Layers

As the newly formed fluted paper emerges from the rollers, a machine applies a starch-based adhesive to its tips. Next, it presses inside and outside liner boards against these adhesive-coated flutes – joining all three layers into one solid, continuous sheet of corrugated board.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Step 3: Curing and Drying the Board

To complete step 3, the machine then moves the newly-glued board over a series of hot plates in order to dry it and set its glue. This step sets and removes moisture, creating a permanent, strong bond between liners and fluted medium, essential for its final strength.

Step 4: Cutting and Scoring the Sheets

At the end of a corrugator, high-speed knives cut individual sheets from the long continuous board into individual box blanks. At the same time, another set of wheels create shallow creases called scores on the board which mark where each blank will fold to create its final box form.

Step 5: Printing, Cutting and Finishing

Once the blank flat box designs have been printed onto them, they move into the converting section of a factory for conversion.

A machine called a flexo folder-gluer usually handles this step, printing company logos, text, handling instructions, graphics onto each box before using its die cutter to cut custom shaped slots or handles onto it.

Step 6: Folding and Joining of the Box

Finally, using the same machine that scored the box blank, folding along predetermined scores, adhering a strong adhesive strip along a side seam tab, pressing sides together tightly enough to form three-dimensional box structure and folding flat for shipping and storage purposes.

These folded boxes will then be packaged up, sent directly to clients who will open them up, fill them up and send them off their way again.

Read Our Book To Grow More In Your Business

Brown Box: Why It Is Thriving in India

India’s corrugated box industry is experiencing exponential growth due to a number of key economic trends, fuelling an incredible surge in demand.

E-commerce Explosion

Every product sold online by companies like Amazon, Flipkart and Myntra requires shipping boxes. With more Indians shopping online every year, demand for this type of packaging has skyrocketed.

Strength of Manufacturing Sector

India has made considerable strides to promote local production of goods through initiatives like “Make in India.” From fast-moving consumer goods (FMCG), such as soaps and biscuits, to electronics appliances and auto parts; packaging is key for storage and distribution.

Read Our Project Report On Paper Industry

Organized Retail

Supermarkets and retail chains like Reliance Retail and DMart utilize corrugated boxes to efficiently move mass amounts of products from distribution centers to their store shelves.

Corrugated boxes are an eco-friendly packaging option, made of recyclable and biodegradable material and fully recyclable or biodegradable. As more consumers and businesses become eco-conscious, paper-based packaging becomes the go-to option over plastic alternatives.

Related Article: How to Start a Corrugated Box Business in India: Step-by-Step Guide

Agriculture and Food Processing Sector

Farmers and food companies alike utilize corrugated boxes to pack and ship fresh fruit, vegetables, and processed food across the United States as well as internationally, protecting its contents to reach consumers intact.

Conclusion

The brown box we see every day at our doors is much more than simply a container; it represents decades of engineering, powerful machinery and an efficient industrial process.

Corrugated industry has become an indispensable yet often-invisible part of modern economy – as manufacturing expands and e-commerce continues its rapid expansion, demand for these versatile, sustainable boxes will only increase exponentially.

Entrepreneurs and businesses find great potential within this strong foundational sector which often comes in simple brown packages.

Corrugated Industry: Frequently Asked questions (FAQs)

Q1: Are a cardboard box and a corrugated box the same?

A: Nope. Cardboard boxes are made from one thick layer, like cereal boxes. Corrugated boxes have three layers, with a wavy bit in the middle for strength.

Q2: How much money do you need to start a corrugated box factory in India?

A: It depends. Big factories need a lot of money for land and machines. Smaller units cost less. You can buy sheets and just print, cut, and glue them.

Q3: Is the corrugated box business profitable in India?

A: Yes, there is good demand. But there’s lots of competition. You need to manage costs and get steady orders to make good money.

Q4: What are the main challenges?

A: The price of paper changes a lot. This affects your costs. There’s also tough competition, you need a big space, and machines can be expensive.

Q5: Is automation important in this industry?

A: Yes, very. Automated machines make boxes faster, save paper, and lower labor costs. Automation helps you stay ahead.