Storage for cold rooms keep food, medicines and flowers from the wrong. He must also fight every day.

Without them, your ice cream melts, your vaccines get worse, and all the Valentine’s flowers are spoiled. The “cold chain” is built on warehouses. This means that things keep the things cold from the farm to the store.

In this article, NPC will guide you about how the warehouse building works.

One District One Product (ODOP): New Startup Ideas Backed by Government Support

How does the storage compares work

Stocks about refrigeration will “get rid of” heat. These buildings are really large refrigerators that blow warm air outside and keep cold air inside.

Many rooms in large buildings need one powerful system. Very simple models work for small buildings. But no matter what kind of installation it is, everything from just above the frost to zero is maintained.

A good air stream is very important inside. When the goods arrive, they are sorted and deployed on high shelves or deep freezers. These numbers are checked using temperature sensors every second.

When it is time to remove products, workers use forklifts that are protected from the cold, and thick curtains maintain warm air.

Read More: Export Opportunities in Oleoresins and Food Additives for Startups

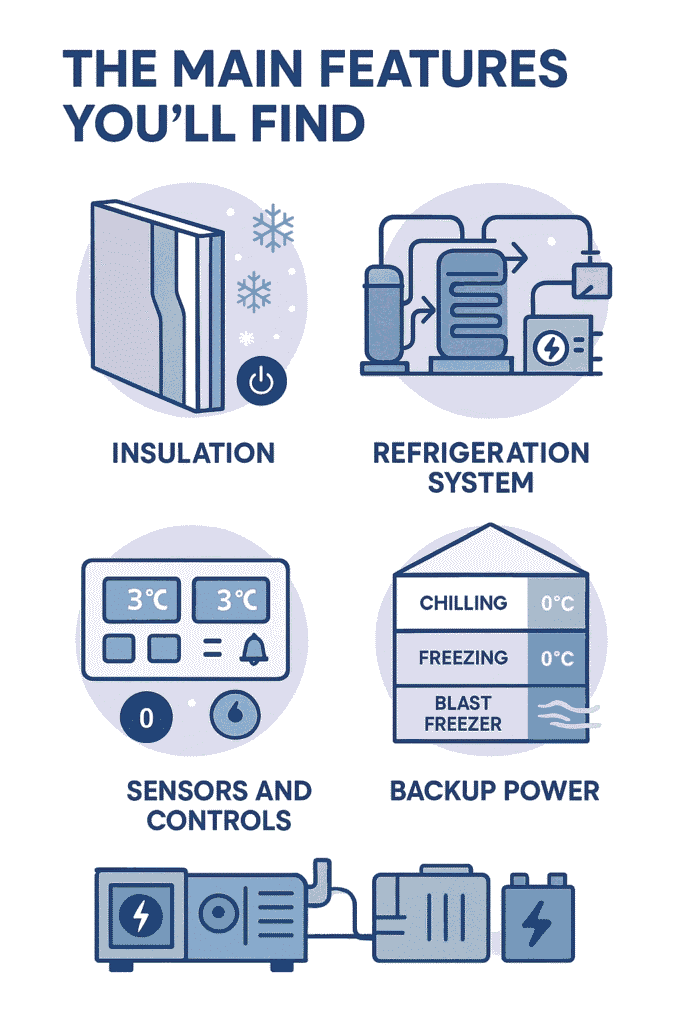

The main features you will find

Isolation

Using thick walls and airtight seals, cool to stay inside. And barrier films stop any water that has been degraded from changing to frost. Because all this is so well done, there is actually a small force.

Cooling system

Tubes and coils of compressors, these machines do the hardest work. And if one of them sometimes fails, large warehouses always have a backup machine at hand.

Temperature zones

One building, many temperatures. Warehouses are kept in cooling (a little above zero) or freezing (far below zero). In some places there are explosive freezers to cool the products very quickly.

Sensors and controls

Digitally systems run all the time and control temperatures. If something goes wrong, the alarms immediately sound.

Backup

If the power fails, it means nothing in these warehouses. Power is returned using strong battery systems and generator

Read More: How are Chicken Processed to Meat, A Complete Guide

Why matters of constant tracking

One slight increase in temperature can be fatal. So much spoiled food, broken drugs and unnecessary money. In a well -managed warehouse there are alarms and sensors every hour at an hour.

Many of them even have a cloud service that shows data about every point live. It is here that employees can quickly capture the problem and deal with it. They can show each step either to inspectors or customers.

If you don’t watch every second, there is one key question: do you really don’t care about your goods?

Design and Settings: Smart movements for energy saving

If you would like to save some quid, uncertainly design. You have to plan exactly how the building faces, you have the accurate angle your docks, and even how wide your streets are.

You must have a scroll door. This is an absolute necessity, if the door is open for one second, all cold air comes out. Now you want higher buildings, because robots do better jobs in finding and storing items and picking up things stronger.

However, these systems also require more powerful cooling and stronger roofs. Also make sure enough electricity is available – storage of cold devices requires a lot of energy.

Read Our Project Report: Click Here

Proven procedures on the spot

Keep the door closed: do not lose your brass chat through the open door. Use quickly closing doors or air curtains to retain warm air flow. Anything that is kept cool.

Multilayer monitoring: Simply monitoring the thermometer will not. Install separate data logs for temperature monitoring. When the inspectors come, you can prove that everything was really cold inside.

Continue regular maintenance: Check regularly and clean everything. This includes coils cleaning, refrigerant gas control, heating cycles – you are going through a list of items each time. Regular checks prevent major problems.

Train your team: Equip your crew with the right gloves and let them knock them properly. You should give them training in how to control forklifts on slippery floors and what to do when something starts to thaw. Good training can protect all participants and everything else.

Having spare parts: Do not rely only on one large cooler. Use several compressors and have a backup system in place. In this way, if something drops, it does not mean that everything will melt.

New technology and trends

Intelligent sensors: People add wireless sensors to measure temperature anywhere – along the corridors, sides of trucks or tanks. These cut out with the need to check all temperatures one by one and immediately visible any problems.

Robots and automation: Automated elevator cars and storage systems save fuel. Robots open the door less times and move faster, so less air gets away.

Save more energy: turn off the power when you finish. If you need to thaw, do it only in places where it affects you most. These things will reduce your electricity account.

Use data to improve: older records can tell you about what kind of things they like to break. See the information you get from your records and find out, for example, when it is a suitable time to defrost the refrigerator or where there are missing lines that formed all these brands.

Read Our Book: Click Here

What is kept in cold?

- Food and drinks: frozen dinners, fresh vegetables, cheese, cows – these are the big things you can find in the storage that are cold.

- Pharma and Biotechnology: Vaccines and medicines must be kept cool and twitching at all times.

- Flowers and special markets: roses and several chemicals and images need the right combination of cold air mixed with water vapor.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

The main idea invented storage of cooling means more than just cold. Cool food, maintains stability of drugs and flowers.

The best warehouses have high insulation, cold rooms with large capacity, 24/7 video monitoring and quick repairs. Employment of new technology is a great help, but always remember the basics: Keep them cool, very carefully attacking your systems and always be ready for trouble.

This way you save a lot. You can follow the rules of success and keep the cold in operation well.

FAQS – QUICK Answers

How cold is it inside the freezer?

Warehouses have different zones: at approximately 0–8 ° C for cooling, –18 ° C frozen and much cooler for certain medicines. It depends on what is stored.

How do you know everything was still cold?

There are monitoring signs on products that tell us if something too warm is so we can pull it out of the shelves; Currently, they are located outside the internal containers trapped in the case of cargo.

Data to rework the freezer?

Make basic checks per month. Every few months he performs larger, deeper checks. Clean and try everything in time.

Do I have to have a backup?

Yes, have backup generators and other compressors. You don’t want to lose everything from a power failure.