If your are going to starting a new company, the manufacturing industry is worth considering. It may be a lucrative move for startups and entrepreneurs, especially when you focus on industries with strong market demand and growth potential.

In modern times, there are several niche areas of manufacturing. This article reviews five new concepts for a manufacturing enterprise that dare to look out the future.

Read More: Start a New Business. Production of Zinc Oxide from Zinc Dross

Manufacturing of Zinc Oxide & Zinc Carbonate (From Zinc Ingots)

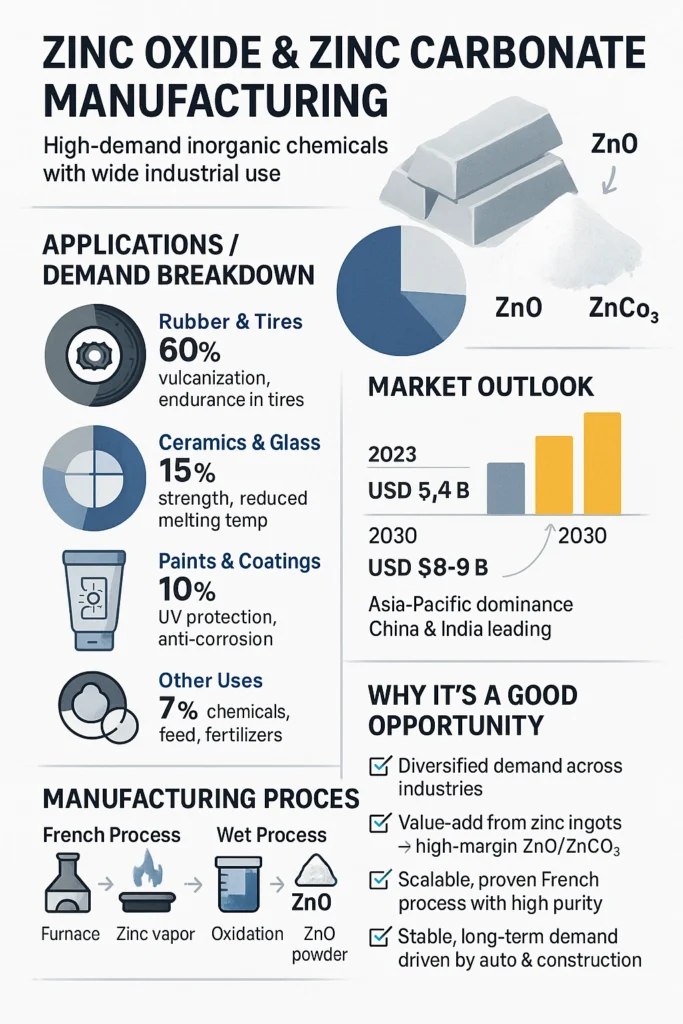

Zinc Oxide (ZnO) and Zinc Carbonate (ZnCO3) are important inorganic chemicals and have wide demand in various industries, then the manufacturing of them from zinc ingots is a profitable and stable business. White powder zinc oxide is important additive in rubber, paint and ceramics as well as cosmetics products. Manufacturers mainly use this in pharmaceuticals and cosmetics.

Market Outlook & Demand

Global ZnO market was about $5.4b in 2023 and it can increase to $8–9b by 2030 with reasonable CAGR of 5–6%. This dominance is due to the rubber and tire industry. It utilises nearly 60% of all ZnO for vulcanisation operations (vital in securing good endurance on tires). The wider the world’s wheels roll, the more tires, ergo zinc oxide there will be.

Other significant demand drivers include:

Ceramics & Glass (~15%): The mineral is necessary to ceramic masses to increase strength and reduce melting temperature for the global construction boom.

Paints & Coatings (~10%): Serves as pigment, and offers UV protection and anti-corrosive properties.

Pharmacy & Cosmetics (~8%): It is a valuable active ingredient in sunscreens, ointments and calamine lotion. Because it provides protection from UV radiation and is antimicrobial when used at high purity. This category is also gaining from the move towards mineral-based make-up.

The Asia-Pacific region, led by China and India, holds a sway over production and consumption on the back of soaring manufacturing and construction industries.

Why It’s a Good Opportunity

This industry is appealing for its diversified, steady demand. One plant can serve multiple industries, providing some diversification to the market risk. The processing of zinc ingot into higher value derived products e.g., ZnO, provides substantial added value.

The new French process (vaporizing and oxidizing zinc, vide infrà), has now been most successfully applied to the production of a high-degree of purity in a reasonably sized installation, consequently rendering its use economic for new comers to this industry.

Manufacturing Details: The primary process is the French process and involves a furnace and zinc fumes. An alternative wet chemical process is capable of producing both zinc carbonate and zinc oxide.

There is the need of quality control, as in different applications the purity and sizes of particles also differ. Compliance with shipping and storing regulations of zinc dust and fume for environment protection is a must.

Read More: Zinc Oxide Manufacturing: A Lucrative Venture for Industrial Entrepreneurs

Hygiene Equipment (Faucets, Sinks and Showers)

Producing sanitary fittings such as water taps, sinks and shower heads is a lucrative business that is directly related to the real estate and housing market. That means that you can find everything from inexpensive commodity-grade products to high-end designer fixtures in this space.

Market Outlook & Demand

Scope-of-the-Report The global sanitary fittings market is large and will continue to gain from strong growth prospects. The faucet market itself reached some 23–25 billion USD in value by 2024, while spending on sanitaryware hardware was estimated at 45–50 billion USD. This segment will grow relatively strong at a CAGR of 7-8%, doubling by the early 2030s.

Key growth drivers include:

Building Boom: The construction of new residential and commercial structures contributes a huge, underlying need for plumbing fixtures.

Home Renovation & Upgrades: homeowners often remodel their kitchens and bathrooms. It creates demand to replace existing fixtures like faucets and showers with new designs. That are contemporary, water efficient and good looking like matte black faucets or a rainfall shower.

Increasing Living Standards: As incomes increase worldwide, consumers are more willing to pay for and buy higher quality, better-designed home products.

Hospitality and Infrastructure: The extended hotel/hospital/ public facility projects demand for bulk sanitary ware in strong design.

The Asia-Pacific will be the largest and fastest-growing market, followed by North America and Europe, where demand is relatively consistent owing to renovations and luxury upgrades.

Why It’s a Good Opportunity

The need for sanitary fixtures is basic and non-stop. One of the ways a startup can enter this market is by targeting a specialized niche, such as low-cost faucets for affordable housing developments or high-end fixtures designed by well-known designers.

The market is becoming more centered on innovation, providing openings for water-saving technologies (low-flow faucets), smart fixtures (touchless taps) and aesthetic customization (a variety of finishes and materials).

Manufacturability: Manufacture requires metalworking such as brass casting (brass is a typical), CNC precision maching, polishing and electroplating (chrome plating is typical).

Massive startup cost for pieces of equipment. Quality control is absolutely crucial to maintain leak-free products and longevity. Differentiation through innovative designs and quality inputs becomes important to compete with established brands.

It is essential that the installation be in compliance with your local plumbing code and lead content standards.

Read More: A Complete Business Plan to Start a Profitable Business of Zinc Oxide from Zinc Dross

Capacitor for ACs, Fans & Washing Machines

Motor run and start capacitors are used in single-phase AC induction motors, which as their name suggests run on a single phase power supply. Production of these components is focused at the vast and expanding consumer appliance and HVAC markets.

Market Outlook & Demand

The world’s motor capacitor market in 2023 was between $3.5 and 4 billion, on track to hit $6-7 in around 2032 at a CAGR of 5-6%. And it’s not isolated growth; this growth directly correlates with sales of appliances.

Asia is the biggest market, but countries like India — where more than 40 million ceiling fans are sold every year — and an AC market that is rapidly growing throughout the continent have driven demand.

Demand is:

Gain Share in Home Appliances: Strengthening disposable incomes in EM also is supporting higher penetration rates of ACs, fridge, and washing machines.

Urbanisation, Electrification: When people have more access to consistent electricity, their use of basic electric appliances also sky-rockets.

The Aftermarket: Capacitors are some of the most frequently used components in repair services, as they have a limited life-span and are replaced more often than any other part type.

Why It’s a Good Opportunity

It was a big spend, it was repeat business.” Partnering with an appliance OEM or large parts distributor can result in consistent long-term revenue.

The capital barrier to enter is not significant compared to heavy industry; production can be expanded or contracted by adding more or fewer winding and assembly machines as demand fluctuates.

There is also plenty of opportunity for import replacement, with a domestic vendor providing faster delivery and often better service than international sources.

Manufacturing: production process includes wind up a Metallized Polypropylene Film. And then it is put into the Casing, terminals are attached, Kapton film sealing; lastly capacitors are Quality tested to ensure the following specifications: capacitance and voltage.

Quality & reliability makes all the difference, and a failed capacitor can damage an appliance’s motor. Success demands electronics development know how, compliance with international safety standards (like UL) and an streamlined production to keep pricing competitive.

Read Our Project Report: Click Here

Lemon Juice Production and Processing

Lemonade manufacture is a new prospect in food and beverage sector. This adaptable customer product is important year round for use in beverages, food applications and as an industrial endeavor. Businesses can stretch from fresh juice bottling to industrial concentrates and powders.

Market Outlook & Demand

Global Learn Juice Concentrate Market, estimated at $ 12 – 14 Bn in 2025, is projected to reach $ 18 – 21 billion by the end of 2035 growing at a CAGR of around4% -5%. The rise is fueled by consumer shifts to natural, healthy beverages from sugary sodas.

Key demand drivers include:

Health & Wellness Trends: Lemon juice is considered a healthy, Vitamin C enriched and low-calorie ingredient with its place in health drinks and detox diets.

Culinary & Food Service Use: A staple for chefs and home cooks. The food service sector needs a reliable source for beverages, dressings, and marinades.

Bottled lemon juice is a great option for busy people because of the convenience factor.

Why It’s a Good Opportunity

A significant advantage is to produce several value added products from a single raw material. Besides juice and concentrate, valuable byproducts you also get from lemons include lemon essential oil (cascading rinds fragrance), citrus pectin(jelly substance) and dehydrated lemon powder.

This diversification allows each feedstock material to be used to its greatest potential, and then combined for maximum revenue generation. It is a business that can be scaled, from selling locally (to cafes and bakeries etc) all the way into industrial supply or export.

Manufacturing process: Washing, juice extraction, filtration, pasteurization and packaging. An evaporator is utilized for concentrate. There are required food safety standards (like HACCP) and regulatory licenses.

The key to success is to ensure a consistent supply of fresh lemons, control for seasonality (through processing and preserving juice during the high production months) and deliver a good quality, fresh tasting product. Branding and promotion are vital when it comes to consumer-facing products.

Read Our Book: Click Here

Modular Kitchen & Wardrobe Manufacturing

Now-a-days modular furniture has become the trend in most modern homes because of its utility and aesthetic look, consuming a minimum space and also quick to install. The making of modular kitchen and wardrobe involves the creation of ready-made cabinets, which are then assembled on site.

Market Outlook & Demand

Global modular kitchen market size was $30–40 billion in 2024 and is anticipated to exceed $50 billion by 2030 (4–6% CAGR). But the story in emerging markets, India for example, is a growing urban middle class adopting modular solutions at a much higher growth far exceeding traditional carpentry demand (greater than 20%+ annually).

Demand is soaring due to:

Urbanization and Smaller Homes: Modular ideas are excellent at utilizing every inch of space in tiny urban apartments.

Ease of Setup: A modular kitchen can be installed in days, while custom carpentry takes weeks – a big plus for both homeowners and real estate builders.

Customization and Style: With multiple formats, finishes and hardware to choose from, you can achieve a modern look tailored just for you. The kitchen is becoming more and more of a social center, and style statement.

Organized Living: These types of systems provide the highest level of organization through custom drawers, pull-outs and accessories.

Why It’s a Good Opportunity

This is an aspirational lifestyle for today’s consumer. There is strong potential for premium pricing and healthy margins as consumers are willing to pay up for good design, quality hardware and professional installation.

The business is scalable; once you have the production streamlined, you can move into other types of modular furniture, like TV units, vanities and office systems. In fast-growing emerging markets, the opportunity is massive and a chance for new brands to dominate.

Manufacturing Notes: Making of this chair necessitates use of precision woodworking equipment; CNC routers, panel saws and edge bonding machines. The model can be a B2B (providing to builders and dealers) or B2C (end-to-end in designing, manufacturing, installing).

It is possible providing you have the design skills, good salesmen with a strong team of fitters. It is important to keep up with interior design trends to remain relevant and make your product offering desirable.

Find the Best Idea for Yourself With our Startup Selector Tool

The Value of a Detailed Project Report

Starting a manufacturing company needs careful planning. Professional counsel, like a Detailed Project Report (DPR), is invaluable.

It offers an iron-clad blueprint of this nature to cover everything including market analysis, technical process, machinery requirement and projected costs and revenues (even the break-even point).

Through the use of a DPR, entrepreneurs can demonstrate their idea’s feasibility, bank loans, and maneuver the intricacies involved in starting a factory. This greatly increases their chances of success.

FAQS

Q1. Do you need enterprise automation on day one?

No, staggered is the way to go. They also recommend starting with basic semi-automatic models to keep costs low. Moving up the line to full automation as your business grows and revenue increases.

Q2. What are the best and cheapest Sources of Funding in India?

Pay attention to the MSME bank loans, that are usually collateral free loans under government schemes such as CGTMSE. Then also look out for certain sops from the Ministry of MSME and state industrial corporations.

Q3. Where can I locate qualified workers?

Employ experienced supervisors, and groom fresh talent from local ITI’s/polytechnics. The best investment is in teaching the skills you need in-house instead of hoping for a well-positioned army of workers.

Q4. Should I begin with B2B or B2C sales?

Start with B2B (Business-to-Business). Selling to builders or other businesses gives you recurring, steady orders and a good reputation rather than expensive retail marketing.

Q5. Does it pay for a startup to be sustainable?

Yes, highly profitable. Focus on efficiency and making money from waste (such as selling lemon peels for oil). It reduces your operating costs, as well as appeals to green-minded customers.