Here is a Detailed Project Report on Plastic Pyrolysis (Waste Plastic to Oil Conversion), its process, market position, demands, investment opportunity and project financials. It comprises a comprehensive analysis of the industry. The report also includes plant capacity, requirement of land and building, raw material detail with supplier list, plant & machinery, flow sheet diagram, total Capital investment along with detailed calculation on rate of return, break-even analysis and profitability analysis.

With the increase of human population, rapid urbanisation, and change is daily lifestyle. The production of plastic has increased at an alarming rate. Plastic is a non-degradable product, and it cannot be destroyed. It is estimated that about 300 million tonnes of plastic waste is created globally, every year. And this number is increasing with each new day.

Visit this Page for More Information: Start a Business in Plastics and Polymers Industry

So we have to reduce plastic waste and recycle it into something more sustainable, and that’s where Plastic Pyrolysis comes in the picture.

Today, globally, we’re facing two major issues that are directly causing Climate Change. One being, Plastic waste and second is sustainable energy. But through Plastic Pyrolysis we can solve both problems, here’s how,

What is Plastic Pyrolysis?

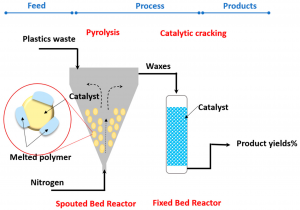

Plastic Pyrolysis is a chemical reaction that involves molecular breakdown of larger molecules into smaller molecules, through the process of heating them.

Pyrolysis, itself means, Fire or heat Breakdown. “Pyro” is Greek for Fire and “Lysis” means to break down.

Pyrolysis is also called Thermal Cracking, Thermolysis, Depolymerization, etc.

It is a process used to turn Plastic into liquid oil, by heating it in absence of oxygen.

The process helps us in two ways, firstly, it creates fuel and secondly, it gets rid of plastic, which helps us reduce non-recyclable waste.

How Does Plastic Pyrolysis work?

As I said before, Plastic Pyrolysis is a process of turning waste plastic into fuel/oil. So how is it done?

Here’s the entire process:-

Now there are three types of Pyrolysis:-

- Slow

- Fast

- Flash.

The difference between the three is the temperature used to conduct and the time taken by the Pyrolysis and the rate of heat.

- Slow Pyrolysis: Slow Pyrolysis takes about 5 to 30 minutes in 400℃ to 500℃ in a lower heat rate of 10℃

- Fast Pyrolysis: Fast Pyrolysis happens at a slightly higher temperature, about 400℃ to 650℃ for 0.5 to 2 seconds at 100℃ heat rate.

- Flash Pyrolysis: Flash Pyrolysis is the fastest of the three. It takes about 0.5 or less residence time from 700℃ to 1000℃ in the heat rate that exceeds 500℃.

The Slow Pyrolysis minimises the oil produced by modifying the solid material, i.e Plastic.

While fast and Flash Pyrolysis creates a lot of oil and gas.

Is Plastic Pyrolysis Sustainable?

While Plastic Pyrolysis helps us get rid of waste plastic, it also has some fall backs. For example, Plastic Pyrolysis releases toxic gases such as PVC that are not harmful to the environment.

It has a high Carbon emission. It emits gases such as CO2 and Water vapour.

Now reading this might make you think, it isn’t sustainable, but when you compare it to the landfills of Plastic wastes, Pyrolysis emits 1/30 of that of landfills. It also significantly reduces the need to extract crude oil and gas from the earth for fuel and virgin plastic resins. Pyrolysis also doesn’t emit Dioxins that are released when plastic waste is incinerated in the landfills.

So Pyrolysis is a sustainable way to harness fuel energy and recycle plastic. Aside from being less polluting, Pyrolysis is also economical. Because the raw material needed, i.e Plastic is available in heaps and as I mentioned before the number is increasing each year.

Read Similar Articles: Plastic Projects

Is Plastic Pyrolysis profitable business?

Plastic Pyrolysis is an extremely profitable business. The two products created in a Pyrolysis plant are Fuel Oil and Carbon Black. Not only are these products versatile, they have a huge market demand.

The main product of Pyrolysis, The fuel oil, is used in Iron Factory, Power Plants, cement factory, restaurant, etc. In India, Pyrolysis oil costs about $500 (₹38800) per tonne.

Their Second Product, Carbon Black is used in rubber tires, inks and coating application.

So yep, Pyrolysis can be a profitable business on a large scale.

Plastic Pyrolysis from Investment Standpoint:

Over the last ten years, the Pyrolysis industry has been growing and maturing. Multinational Companies such as Michelin, Bridgeton, BASF, and Continental have invested and entered the pyrolysis industry.

As the world is trying to create sustainable energy, due to global warming and climate change. It seems like investing in such projects could be profitable and might make you great gains.

Pyrolysis had a bad rep in the beginning period, but over the decade, with more and more advancement in technology and methods, the Pyrolysis industry has turned the wheel around.

The rise in demand of Pyrolysis oil in the petroleum industry might boost its market growth. At the same time, partnerships between companies and Pyrolysis plants might help the boost.

In September of 2019, Setra partnered with Preem, and they’ll try to produce Pyrolysis oil from sawdust. BTG-BLT teamed up with TechnipFMC to extract bio-oil.

Key Competitors in Global Market.

- BTG Biomass Technology Group

- Divya International

- Bluebear

- Biogreen

- Chevron Phillips Chemical Company

- TechnipFMC

- Setra

- Preem

- Enekem

- Ensyn Corporation.

See More Links:

- Start a Business in Asia

- Start a Business in Potential Countries for Doing Business

- Best Industry for Doing Business

- Business Ideas with Low, Medium & High Investment

- Looking for Most Demandable Business Ideas for Startups

- Startup Consulting Services

- Start a Business in Africa

- Start a Business in India

- Start a Business in Middle East

- Related Videos

- Related Books

- Related Projects

- Related Market Research Reports

KBR_20Art22