The greatest business idea of our era is making money from waste. Just to give you a little example: we can produce nicotine from tobacco garbage. But instead of jettisoning stems, leaves and dust, the entrepreneurs will turn it into a product they claim is in high demand around the world.

Nicotine is a common ingredient in many other industries, including quit-smoking products like gums and patches, vaping liquids and bio-pesticides. And in an extraction business, you don’t just make money but you also clean up waste from the environment.

Let’s read our latest blog to know more about it.

Why Nicotine made from Waste is the Next Big Thing – Market Opportunity

Market for nicotine is expanding rapidly in various sectors. This makes a good entrepreneurial opportunity for new entrants.

Pharma industry: Requires High Purity Nicotine for NRT (Nicotine Replacement Therapy) products such as gums, lozenges and patches.

Vaping market: Purified nicotine and nicotine salts used to make e-liquids for exports (India prohibited local sales but there’s high demand for exports).

Agricultural: Several countries continue to use nicotine sulfate and dusts as natural insecticides on a limited scale (organically) in commercial crops.

The global nicotine market will worth around USD 600 million (in the year of 2025) and grow over three times by coming of the year 2034. India is the second largest grower of tobacco and that guarantees a constant, cheap supply of raw material.

Read Our Book: Click Here

Raw Materials for Tobacco Waste

A nicotine industry starts with raw material, and there is no dearth of tobacco waste in India.

Tobacco waste sources include:

- Cigarette & beedi making: Cause dust from cutting and rejected leaves.

- Chewing and hookah tobacco: Create remnants and dust.

- Farmers and auctions: Sell unsold or low-grade tobacco leaves.

The majority of this waste is 1–7% nicotine. Startups can drive yield and profit by focusing on high-nicotine waste, such as Nicotiana rustica. For saving on transportation costs, plants should come up in or around those important tobacco-growing states such as Andhra Pradesh, Gujarat and Karnataka.

How Nicotine Is Extracted From Tobacco

After raw material is prepared the next process would be nicotine extraction. There are five simple steps in order to explain the procedure:

- Dry and pulverize the waste to a powder.

- Soak in solvent or alkaline water to leach nicotine.

- Filter or centrifuge to eliminate remaining solids.

- Distill or evaporate to reclaim solvent and concentrate nicotine.

- Further purify to pharma-grade or convert into nicotine salts.

For startups, solvent extraction coupled with distillation is the most economical. Fancier options, such as using supercritical CO₂ to extract the oil, are cleaner and also more expensive.

Read More: The Profitable Extraction of Nicotine from Tobacco Waste

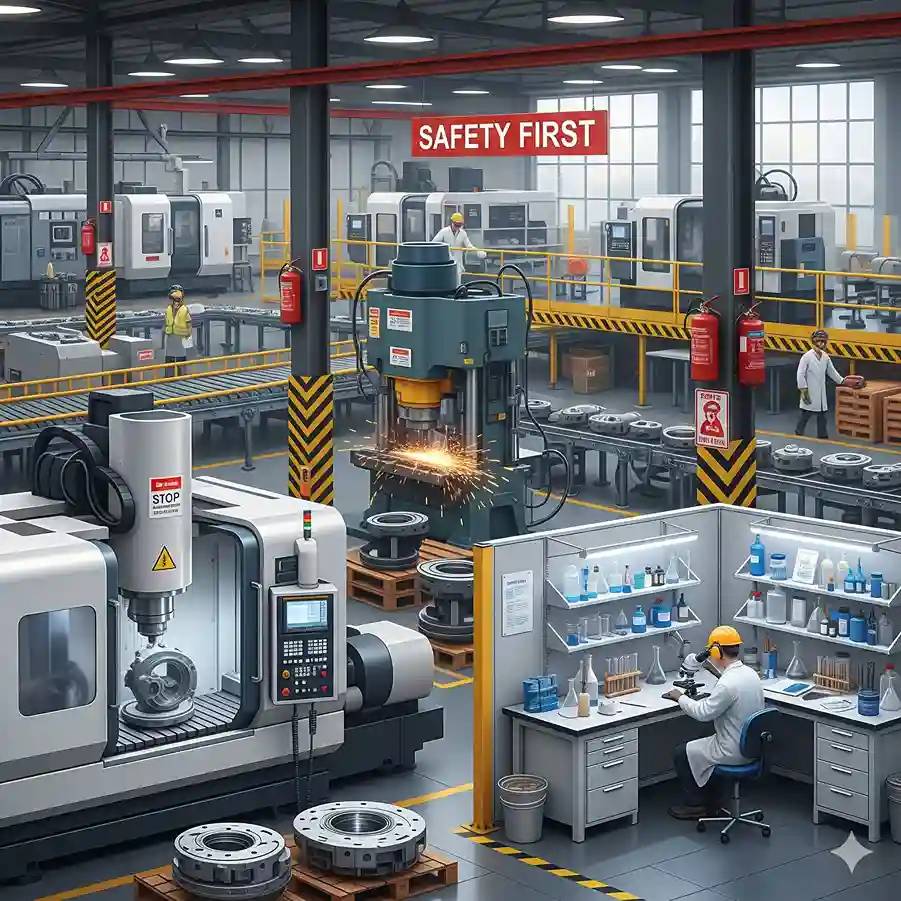

Equipment and Safety

Operating a nicotine unit takes straightforward, dependable machinery and robust safety. Use stainless-steel extraction tanks with agitators to extract the nicotine from the waste. Then filter or centrifuge to remove solids. A solvent recovery distillation system recycles the alcohols and saves money.

Support apparatus such as boilers, condensers, pumps and secure storage tanks help things along. Maintain a small in-house lab to test how much nicotine is in each batch and for trace dirt or solvents that remain in the product.

Nicotine is a poison and many solvents are flammable so ensure the workplace is safe with good ventilation, fire systems, spillage control measures, etc., and provide protective clothing for staff. Simple written work instructions and consistent training keep everyone safe and help prevent mistakes.

- Essential equipment: Extraction tanks + Agitators, Filters/Centrifuges, Distillation with solvent recovery, Boilers/Condensers/Pumps/Safe Tanks

- Lab staples: simple point-of-testing tools for testing nicotine and impurities

- Your safety must-dos: Good ventilation, fire protection, spill trays, PPE, clear SOPs and guidance.

Quality and Compliance

Buyers demand pure, uniform nicotine, and so quality checks are central. Train or perform basic lab tests such as HPLC or GC to confirm purity, look for leftover solvents and related alkaloids.

If you plan to sell to pharma, follow Good Manufacturing Practices (GMP), such as keeping clean rooms, calibrating equipment and clearly documenting every batch. Obtain state pollution control approvals for legal matters.

For pharma-grade products, you might require drug permissions. If you sell nicotine sulfate as an insecticide for export, ensure the product is registered and complies with the regulations of the destination country.

You are required to have an Import-Export Code (IEC) and follow packing and marking requirement for hazardous goods for all export.

- Quality tools: HPLC/GC testing for purity and testing of solvents and alkaloids.

- Pharma rules: GMP, batch records, clean rooms, calibrated tools

- Legal basics: Pollution consents, drug/insecticide permits, IEC, Hazardous-goods packing & labels

Read More: Red Chili Oleoresin Manufacturing Plant

Products and Revenue Streams

Waste nicotine can be recycled to other valuable products, as follows:

- Pharma-grade nicotine- from NRT, yields high margins.

- Nicotine salts- exported for e-liquids, big hit in foreign markets.

- Nicotine sulfate (40% solution)- exported to organic agriculture.

- Vitamin B3 (niacin/niacinamide)- derived from nicotine, sought after for supplements.

- By-products/solanesol– The residue is used to make CoQ10, a health supplement.

A smart start-up starts with one product and slowly diversifies.

Read Our Project Report: Click Here

Trade and Export Potential

India is a leading global nicotine exporter, sending the supplies to the US, Europe, Russia and Africa. Even as exports rise, some pharma companies in India continue to import ultra-pure nicotine. This creates an opportunity for startups domestically in import-substitution.

Then, there are government incentives such as duty drawback and export support schemes which turn exports even more lucrative. With correct packaging and hazardous-goods compliance, the export market is simple to tap.

Read More: Biodegradable Products Business: Profitable Eco-Friendly Opportunities in 2025

Learning from the Leaders

Indian manufacturers have ramped up through investment in quality, modernization of equipment and coming in line with rigorous buyer specifications.

Some firms began with sulfate solutions because they could derive steady cash flow quickly before moving into higher-purity lines once profits permitted. Others went straight for pharma grade and locked in long-term contracts.

The common denominator is simple: Master one product well, document quality, remain compliant and then expand into related grades and markets.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

Nicotine production from waste of tobacco is a lucrative and green business. With Indian’s raw material advantage, demand from across the world and government backing, Startups can grow fast.

Entrepreneurs therefore have an opportunity to create a sustainable and globally competitive business by concentrating on waste sourcing, safe extraction, guaranteed quality from the source, and compliance.

Begin with a single product and grow one product at a time. Your business will grow consistently in this high growth industry.

Nicotine Manufacturing Process: FAQS

Q1. Is it legal to produce nicotine in India?

Yes if you have legal permission from Pollution Control Board, Drug Authority/Insecticide Board (depending on two products).

Q2. How much investment is needed?

A small plant, so this is wicked strong, requires ₹5-7 crore; pharma-grade lines are more immorally expensive.

Q3. Can a startup export nicotine?

Yes, India is a top exporter. You have to have an IEC and you must adhere to hazardous-goods shipment regulations.

Q4. Which product is most profitable?

Pharma-grade nicotine and its cousins, nicotine salts, have the biggest margins.

Q5. Where do I start the plant from?

Close to tobacco centers at Andhra Pradesh, Gujarat or Karnataka to facilitate easy access of raw material.