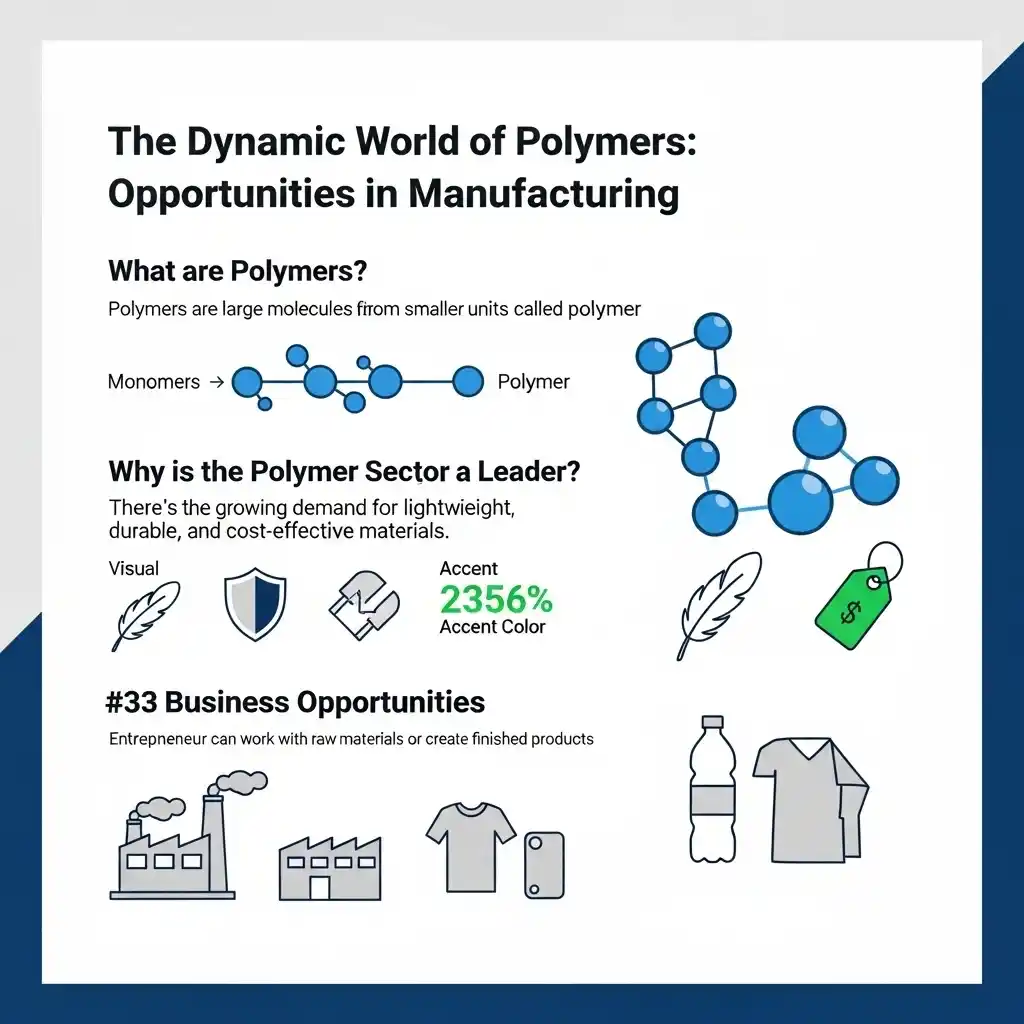

The polymer sector is one of manufacturing’s most dynamic and versatile industries, with countless opportunities for business. Polymers are large molecules that are created by joining monomers. They are used for packaging, constructions, textiles and electronics.

This sector is a global leader due to the growing demand for lightweight materials that are durable and cost-effective. Entrepreneurs who want to get into the polymer industry can explore different segments, ranging from raw materials to polymers processed into consumer and industrial products.

This highly lucrative field has a lot of growth potential because it is possible to customize polymers according to specific needs.

Polymer Business: Scope

This is a vast market that continues to grow due to the technological advances and increased applications in all industries. Globally, packaging is a major demand, particularly for consumer goods, food and beverages. Polymers are used heavily in the automotive and aerospace industries for lightweight, fuel efficient designs.

These are used in healthcare for medical implants, drug delivery systems and surgical instruments. Polymers are also used in the electronics industry for flexible circuits, insulation and casings. The polymer industry is highly scalable due to its diversity, and offers options for both small businesses and large corporations.

This sector is also moving towards eco-friendly, biodegradable materials. This creates new opportunities for innovation.

The Types and Applications of Polymers

To succeed in this industry, you must understand the different types of polymers. Thermoplastics, thermosetting materials, elastomers and specialty polymers are the four main categories of polymers.

Thermoplastics such as polyethylene (PE), polypropylene, and polyethylene (PP) can be reshaped many times. They are commonly used for packaging, bottles and containers. Thermosetting Plastics are used for adhesives, electrical components, and coatings because they are heat resistant and durable.

Elastomers such as rubber are essential in tires and seals. Specialty Polymers, like fluoropolymers, serve the aerospace and electronics industries. Each type is tailored to a specific market. This allows businesses to diversify or specialize based on their goals.

Read More: Start a Profitable Styrene Acrylic Emulsion Plant: Cost & Market Guide

Manufacturing Process Overview

To start a polymer company, you need to have a good understanding of the production process. Addition and condensation polymerization are two polymerization processes that can be used to manufacture polymers.

Monomers are linked together in addition polymerization without any by-products. Condensation polymerization creates a polymer as well as a small water molecule. Polymers are then processed by extrusions, blow moldings, spinning, and moldings to produce products.

Extrusion, for example, is perfect for pipes, while injection molds are commonly used in toys and auto parts. These techniques help businesses produce high-quality products with precise specifications that satisfy customers.

Market Trends and Opportunity

Technological innovations and environmental concerns are causing a rapid change in the polymer industry. Biodegradable plastics and polymers are becoming more popular as an alternative to petroleum products.

Read More: Start-Up an Eco-Friendly Business of Bio Plastics and Biodegradable Products Manufacturing

Businesses have been encouraged to invest in green manufacturing and recycling techniques due to the growing focus on sustainability. Smart polymers that have unique properties such as shape memory and self-healing are also gaining in popularity, which opens up new markets for healthcare and robotics.

Construction and packaging industries in countries with high growth rates offer great opportunities for polymer producers, particularly those who are willing to innovate and provide cost-effective eco-friendly solutions.

Start a polymer business: Key steps

Entrepreneurs who want to enter the polymer business must choose their business model first. They can either focus on producing raw polymers, finished products, or recycling services. To identify the target market and determine investment requirements, a detailed feasibility study is required.

In order to set up a production unit, you will need to select polymerization methods, source raw materials and ensure compliance with environmental regulations. In this industry, marketing is crucial as the industries look for suppliers that can deliver high-quality products at affordable prices.

Small businesses can begin by manufacturing niche products such as specialty coatings, or they can grow to large-scale production plants that serve global markets.

Read Our Project Report: Click Here

Investment and Infrastructure Needs

A polymer business will require a significant amount of investment, particularly if you are setting up large production facilities. Initial costs include land and machinery, including polymerization equipment and extrusion and mold machines.

They also include quality testing laboratories and packaging facilities. Entrepreneurs can begin with small-scale processing facilities, and then outsource the raw polymer production. The infrastructure must meet safety standards as this industry uses chemicals and equipment that operates at high temperatures.

The investment in training and skilled personnel ensures efficient operation. Certifications like ISO standards help gain the trust of buyers and facilitate entry to international markets.

Environmental Impact and Recycling

Polymer waste and pollution have been a source of criticism for the industry, but there are also opportunities to address this issue. Many companies invest in polymer recycling facilities that turn waste plastics back into raw materials. This reduces environmental impact and production cost.

Biodegradable and biocompostable polymers are another step towards sustainability. Entrepreneurs who enter this industry must consider integrating recycling into their business model to meet the growing demands of consumers and regulators.

Focusing on eco-friendly methods not only enhances the brand’s image, but also attracts investors and customers who are environmentally aware.

Read Our Book: Click Here

Polymer Industry Challenges

The polymer industry is profitable but also comes with some challenges. Entrepreneurs must be prepared for these. The fluctuating crude oil price affects raw material costs as most polymers are petroleum based. Businesses must constantly innovate to stay competitive in a highly-competitive market.

The environmental regulations are getting stricter and companies must adopt sustainable practices. In addition, the capital and technical expertise required to set up large-scale manufacturing facilities is high.

Businesses that are innovative, sustainable, and have efficient manufacturing processes can overcome these obstacles and establish a strong presence on domestic and international markets.

Read More: Profitable Chemical Products in High Global Demand with Local Manufacturing Opportunities

Future of the Polymer Business

New technologies are reshaping the manufacturing process and product design, which bodes well for the future of polymer. The demand for specialized materials is expected to rise with the advent of additive manufacturing (3D printing), while smart and bio-based polymers are likely to create new opportunities in high-tech industries.

Packaging will continue to be a key driver of growth. Developing countries’ construction and manufacturing industries will expand, creating huge markets. Entrepreneurs that invest in R&D, use eco-friendly products, and diversify offerings will thrive in this changing industry.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

The polymer industry is a profitable and dynamic sector, which offers many opportunities for global growth, innovation, and sustainability. Entrepreneurs can select their niche according to resources and expertise.

The industry is expected to grow due to the increasing demand for packaging, construction, technology, and healthcare.

Success requires careful planning and compliance with environmental regulations. It also demands a willingness and ability to embrace new trends, such as recycling and bio-based products.

Entrepreneurs who enter this market now have the opportunity to create thriving businesses which not only generate profits but also contribute towards a sustainable future.

Frequently Answered Questions (FAQs).

Q1. Why are eco-friendly products often priced higher?

They are more expensive, but they have a higher price because of their eco-friendly customers.

Q2. What are the skills needed to run a business in polymer manufacturing?

It is important to hire engineers and technicians with the right skills.

Q3. Is recycling polymers a great business idea?

Recycling polymers reduces waste, conserves resources and meets regulatory standards. This also provides an opportunity to create affordable raw materials.

Q4. What are the key challenges facing this industry?

These include the high level of competition, the fluctuating prices of raw materials, the environmental regulations and the need to invest significant capital.

Q5 . What industries are the biggest consumers of polymers?

These include packaging, automotive, electronics, textiles and healthcare.