Particleboard, also commonly called chipboard, is an extruded engineered wood product made from wood chips or and a synthetic resin. As compared to the wood which is conventionally used, Particle Board is cheaper and denser. Particle Boards can be made more attractive with the help of painting and by using wood veneers. Oriented strand board (also known as chipboard) is a different type of fiberboard that uses machined wood flakes and provides more strength than particleboard. Particleboard is the lightest type of fiberboard. Different grades of particleboard come up with different densities.

Start a Business in Wood Processing Industry, Click Here

Opportunities for Particle Board Manufacturing Industry:

The global particle board market is expected to increase at a CAGR of around 6.1 percent in the next five to six years. One of the important factors projected to drive the growth of the target market is an increase in building activities around the world. Rapid urbanization along with the increasing desire among people to provide the inside of a building a more beautiful appearance is some of the main reasons expected to boost the global ParticleBoard Market. Particleboards are a cost-effective alternative to plywood, which is another element expected to drive the global ParticleBoard market. Because of its exceptional sound-absorbing capabilities, it is frequently used in places like music halls and recording studios.

Particleboards can also be coated, painted, or wallpapered to enhance their overall aesthetic value. This, together with the growing working population and the growing popularity of modern offices, is driving up demand for particle boards and henceforth increasing the opportunities in this sector.

In addition, the rising popularity of outdoor activities is fueling industry expansion and opening up more and more opportunities. Aside from that, prominent producers are concentrating on increasing the intrinsic qualities of particleboards by utilizing raw materials derived from crop plants. Natural fibers such as wheat, cotton gin, rice, banana, etc. are also being used to launch a variety of products, resulting in a positive market outlook. The global ParticleBoard market is expected to benefit from the development of innovative particleboard manufacturing processes in the future.

Project Report on Materials:

The material report’s objective is to aid and advise an entrepreneur in collecting accurate information on the project’s material requirements. It includes vital details including raw material needs, a description of machinery, and the plant’s manufacturing procedures. Plant capacity, project setup costs, operational capital requirements, expected sales, and profit are all included in the report.

The project exemplifies the complete (both quantifiable and qualitative) investigation of antique data, profits, crucial progresses, along with the critical policies espoused by vital establishments catering to project. This offers dynamic and in-depth visions in directive to illustrate the global market situation.

The materials offer a descriptive breakdown of the porter’s five forces study united with SWOT investigation so as to deliver commercial interrelated statistics and info’s. Porter’s five forces model understands the inclusive inexpensive scenario that is prevailing in the arcade. Furthermore, the SWOT analysis recognizes mutually the constructive and destructive traits of the project expansion which impacts the company evolution and development in directive to endure and subsist in the elongated route.

Read Similar Articles: Wood based Products

Our Pre-Feasibility Study Report:

Particle board market characteristics, including industry growth drivers, demanding conditions, opportunities, risk, constraints, and hazards, were studied by Entrepreneur India. A production value study, which comprises raw material analysis, product fee trend, Mergers & Acquisitions, growth, key product suppliers, particle board’s marketplace awareness charge, and manufacturing process analysis, is also included in the pre-feasibility research. The research also includes a market result characteristics analysis that focuses on technical advancement, consumer demand patterns, and external environmental exchange to aid startups and entrepreneurs.

The report provides a comprehensive market analysis for each of the product segments. A cost chain analysis gives you extensive information on how value is created at each level. The pre-feasibility study examines the particle board market’s drivers and limits, as well as their influence on demand throughout the forecast period.

The study also examines all of the critical factors that a firm should consider before joining the particle board industry. It is entirely based on current financial data and contains detailed information on the primary method flow, raw material needs, reactions, application costs, working fees, capital investments, forecasts, and margins, among other things. This text should be read by entrepreneurs, researchers, experts, commercial business strategists, and anybody else interested in the particle board industry. The report also examines the sales, value, market share, and future development plans of the major particle board producers. The market’s sales, duration, quality, and estimates are all mentioned.

Watch Video: Particle Board (Wood Base) – Manufacturing Plant

Latest Market Trends of Particleboard Industry:

Because of the changing lifestyles of today’s people, furniture style preferences have shifted dramatically in recent years. The use of Particleboards in the furniture sector has been rising vastly because of their high-temperature and fire resistance. Furniture, such as chairs, tables, sofas, beds, and cupboards, has seen a considerable increase in demand due to rising house construction, population, and income levels around the world.

Interior design concepts for houses, flats, and workplaces are always evolving in the furniture sector. This is pushing research and innovation, particularly in terms of form, size, and color. This is predicted to increase the volume of furniture manufacture around the world.

The furniture industry’s major markets are Germany, China, the United States China is the world’s largest exporter of wood furniture to the European Union.

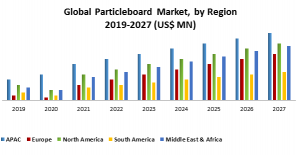

Because of the growing construction and furniture industries in countries like China, the particle board market in the Asia-Pacific region is expected to grow rapidly.

Due to its ever-increasing population, rising affluence, and rapid urbanization, China has the largest market base in the Asia-Pacific area. It is also a key manufacturing center for nearly every industry. Owing to the latest market trends, the global ParticleBoard is forecasted to grow in near future.

Related Feasibility Study Reports: Wood and Wood Products, Plywood, Board, Particle Board, Wooden Furniture, Bamboo, Engineered wood, Forest product, Lumber, Tree, Wood drying, Wood plastic composite, Door, Window, Modular Furniture, Timber, Woodworking, Decorative Laminated Sheets

Reasons for buying the report:

- This report helps you to identify a profitable project for investing or diversifying into by throwing light to crucial areas like industry size, demand of the product and reasons for investing in the product.

- This report provides vital information on the product like its definition, characteristics and segmentation.

- This report helps you market and place the product correctly by identifying the target customer group of the product.

- This report helps you understand the viability of the project by disclosing details like raw materials required, manufacturing process, project costs and snapshot of other project financials.

- The report provides forecasts of key parameters which helps to anticipate the industry performance and make sound business decision.

What Is the Manufacturing Process of ParticleBoard?

Particleboard is made by combining wood or jute-stick particles with a resin and molding the combination into a sheet.

The steps in the manufacturing process of ParticleBoard are: –

- The raw material is fed into a disc chipper. The particles are then dried, and any particles that are too large or too small are screened away.

- The particles are then sprayed with resin in a thin mist.

- Other chemicals are used in panel production, such as wax, dyes, wetting agents, and releasing agents, to help with processing. The particles are piled into a continuous carpet after passing through a mist of resin sufficient to coat all surfaces.

- After that, the ‘carpet’ is split into discrete, rectangular ‘blankets,’ which are then compressed in a cold press.

- The flakes are then weighed and are distributed by an air jet in graded-density particleboard, which throws finer particles further than the coarse ones.

- The particles may build up from fine to coarse and back to fine using two of these jets, which are reversed.

- To minimize thickness, the produced sheets are cold-compressed. After that, the boards are cooled and sanded. They can then be offered as raw board or with a wood veneer or laminate surface added to improve the appearance.

Read our Books Here: Wood, Bamboo, Coal, Lignin and Its Derivatives

ParticleBoard API Manufacturing Industry FAQs:

- What Is the Growth Rate of ParticleBoard Globally?

The global particle board market is expected to increase at a CAGR of around 6.1 percent

(2019-2025).

- What Are the Driving Factors of The ParticleBoard Market?

In the manufacturing industry, there is a growing demand for lower-cost fiberboards. Increasing R&D investments in fiberboard product innovation and development

- Which Are the Leading Players of The Particleboard Market?

The prominent players in the global particleboard market are:

- Roseburg

- Timber Products Company

- D&R Henderson Pty Ltd

- Uniboard

- Dakota Premium Hardwoods

- Green Land Particle Board

- Century Plyboards India Ltd

- Associate Decor Limited

- Boise Cascade

- Krifor Industries

- Shell Laminates Pvt. Ltd

- What are the primary global Particle Board market trends?

The expanding number of construction and building projects, as well as end consumers’ increased awareness of particle boards’ eco-friendly character, are two important market trends.

Watch other Informative Videos: Wood and Wood Products, Plywood, Particle Board, Wooden Furniture, Bamboo, Forest Product, Wood Plastic Composite, Timber and Woodworking

Conclusion:

We at NPCS want to help you grow by providing solutions that scale to fit your new operations, reducing risk and maximizing the return on your application investments. Our expertise for excellence has been valued by a vast number of our Indian and NRI clients, which says volumes about our devotion and dedication to each client’s success. NPCS is a well-known technical consulting that focuses on specific services, and we’ve been following a tight system and method to ensure only the highest quality in accordance with our clients’ needs in this rapidly increasing and changing market. We have a full complement of highly experienced Technical Consultants, Engineers, Economists, and Technologists with expertise in a variety of fields, and we take great satisfaction in working together as a team to achieve our common goal of exceeding perfection. Many of our clients’ investments have been successful thanks to the efforts of our team.

See More Links:

Start a Business in Potential Countries for Doing Business

Best Industry for Doing Business

Business Ideas with Low, Medium & High Investment

Looking for Most Demandable Business Ideas for Startups

Start a Business in Middle East

DD_Art2022