Why LED Lighting Manufacturing Is a Promising Opportunity

In the ever changing industry landscape in India as well as around the world the LED lighting manufacturing industry is one of the most exciting and promising industries. As more countries are committing to reducing their energy consumption and promoting sustainability, LED lighting manufacturing has replaced traditional lighting in industries, homes, infrastructure, and public utilities.

For entrepreneurs, especially those who have backgrounds in pharma or manufacturing of chemicals, a move into LED manufacturing is an opportunity to diversify their business. This industry is not just in line with the policies of the government that promote energy-efficient technology, but also has a strong demand across a variety of different market segments.

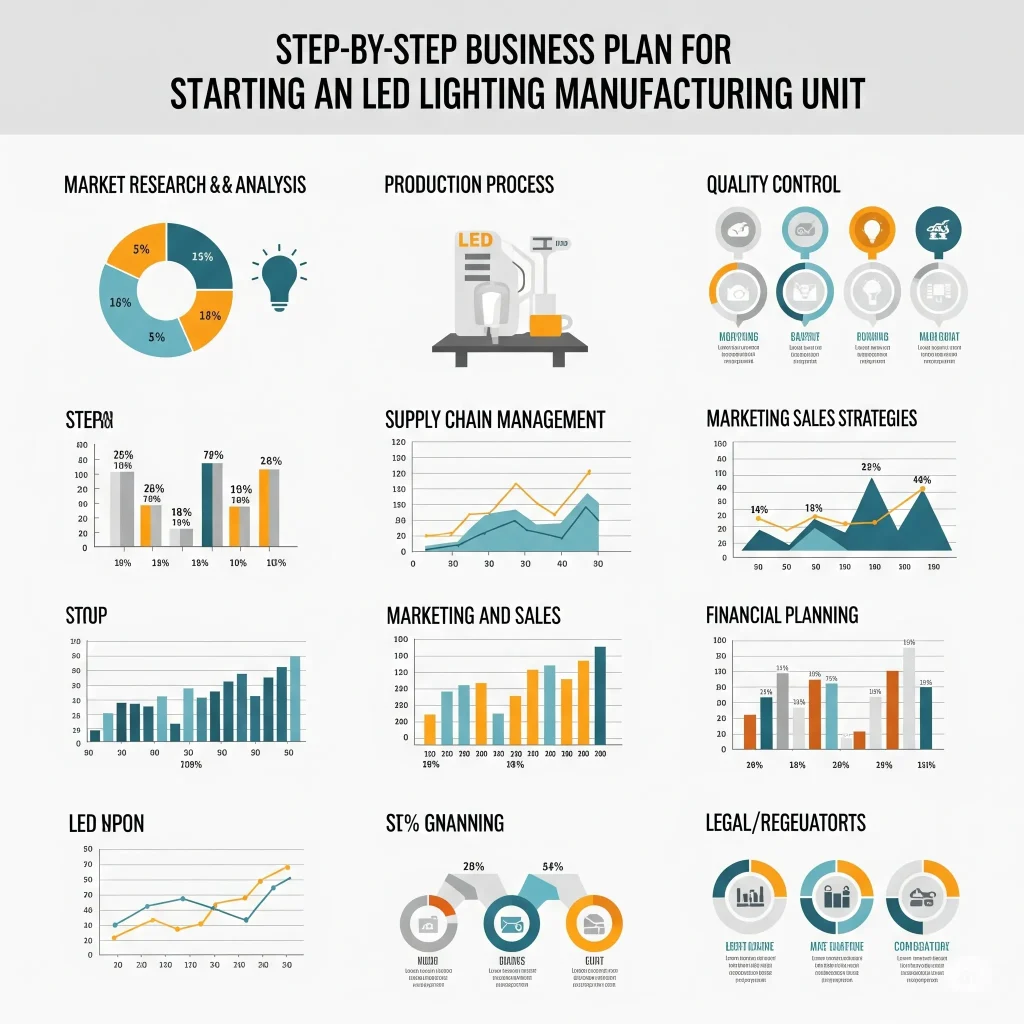

This article offers a comprehensive business plan that is step-by-step designed for industrial entrepreneurs and startups seeking to enter the LED lighting manufacturing industry. The article outlines the market outlook and trends in demand, the manufacturing process, and crucial steps to launch and grow the business effectively.

Understanding the Market Potential of LED Lighting

Growing Demand and Market Forecast

The market for LED lighting in India has seen remarkable growth over the last few years. In 2023, analysts valued the market at over Rs 30,000 crore, and they predict it will grow at a 13 percent compound annual rate over the next five years, potentially exceeding Rs 60,000 crore by 2029. This is due to several factors, including increased use of the technology in commercial, residential, and government sectors as well as increased export demand.

The government’s flagship programs such as UJALA as well as the Street Lighting National Programme (SLNP) have played an important role in replacing the inefficient lighting with LED technology, resulting in steady demand. In addition, the rise of urbanization, consumer awareness and the move towards smart cities are further accelerating this trend.

Opportunities for exports are growing as well, with Indian LED products becoming more popular in countries such as Africa and in the Middle East, and Southeast Asia due to their low prices and improved quality.

Pharmaceutical manufacturers experienced in producing intermediates and APIs can leverage their production expertise and supply‐chain management skills by entering LED manufacturing as a profitable alternative.

Related: Top 10 Small Scale Manufacturing Business Ideas in India

Step 1: Conduct In-Depth Market Research and Feasibility Analysis

Conducting a thorough market research is essential. This is about assessing the market demand across different segments of products like bulbs, tube lights, panel lights streetlights, and LEDs that are specialized (smart or powered by solar). Knowing the market landscape, trends in pricing customers’ preferences, as well as regulations will help you formulate your business’s strategy.

Apart from conducting desk research, entrepreneurs should also contact potential buyers—retailers, government procurement agencies, and commercial companies—to confirm their quality needs and expectations.

To help with this, experts from firms like Niir Project Consultancy Services (NPCS) create an extensive Market Survey and technological economic Feasibility Reports. These reports provide crucial information regarding manufacturing processes and raw materials, as well as plant layouts, as well as market dynamics, helping entrepreneurs to make informed choices regarding their LED manufacturing business.

Step 2: Define Product Range and Business Model

The LED lighting market has a wide range of options, each of which has its own production complexities and potential markets. If you are a newbie you can begin by the assembly of basic LED bulbs and tube lights, which require easy manufacturing processes and have an extensive market demand.

You can also focus on specific products such as street lights, downlight fixtures, or smart LEDs featuring app‑based sensors and controls. These types of products typically are more difficult to enter but they also have premium prices and an ongoing demand for institutional lighting.

Your business’s model should also be determined early on. Choose whether you’ll:

- Manufacturing under your own brand (B2C)

- Offer your components or finished goods directly to established B2B brands by acting as an Original Equipment Manufacturer (OEM).

- Government and institutional tenders targeted using bulk contract supply

Each method has distinct business and marketing implications and your strategy for product development must align with your marketing strategy.

Step 3: Select Location and Establish Manufacturing Facility

Selecting the best location to build your LED lighting manufacturing unit is crucial to operating effectiveness and efficiency. Choose industrial areas with an efficient power source, connection to suppliers of raw materials and customers, and proximity to clusters of electronics manufacturing.

Indian state governments provide subsidized industrial land, infrastructure, and other incentives to electronics and LED producers within special economic zones (SEZs) and electronic manufacturing clusters (EMCs).

The layout of the facility should allow separate zones to store raw materials PCB assembly, driver circuit manufacturing Quality testing, as well as packaging.

Related: How to Start an LED Manufacturing Business

Step 4: Source Quality Raw Materials and Equipment

The production of LEDs is heavily dependent on the availability and the quality of components like LED chips, printed circuit boards (PCBs) heat sinks, driver circuits aluminum or plastic housings and diffusers.

Building trusting relationships with suppliers is essential. A lot of components, particularly LED drivers and chips could start out as imported items, however the growing capacity of manufacturing in the country is reducing the need for imports.

They also include reflow ovens, soldering stations and testing equipment. Based the budget you have and size, it is possible to choose fully automated or semi-automated production lines.

Step 5: Recruit Skilled Workforce and Invest in Training

A skilled technical workforce is essential to ensure product quality and productivity. You’ll need engineers and technicians with expertise in electronic assembly and quality control experts, along with production directors.

Continuously developing skills is equally crucial. The training on best practices, testing protocols and safety standards will improve the efficiency of operations and minimize errors.

For those in the pharma or chemical industry, using the existing quality assurance and technical experience can ease the transition to LED manufacturing.

Step 6: Obtain Necessary Certifications and Regulatory Approvals

Conformity to standards is not a matter of negotiation. For instance, the Bureau of Indian Standards (BIS) certification is required for all LED lighting products that are sold in India. It involves testing the product to ensure electrical safety and energy efficiency as well as longevity.

If you intend to export, certifications such as CE labelling (Europe) or RoHS compliance with hazardous substance limitations are crucial to ensure access to markets.

Make sure you have the right documentation in place and work with accredited testing labs to speed up the certification process of certification. By ensuring compliance early, you protect your brand and also facilitate the sales process for both institutions and government agencies.

Step 7: Implement Quality Control and Testing Procedures

Maintaining consistent quality differentiates successful manufacturers. Our team implements quality assurance at every step: inspecting raw materials, installing components, integrating the driver, and finally testing the finished product.

Tests on lumen output as well as energy consumption and color temperatures thermal management and durability in various environmental conditions, assure high-quality.

Automated testing equipment can reduce human error and speed the quality inspection process. Feedback loops to analyze defects will allow you to continuously improve your processes.

Step 8: Develop Branding and Marketing Strategy

In a highly competitive marketplace your company’s reputation for reliability and efficiency in energy use is essential. Create packaging that is professional and highlights the key features of your product and complies with markings.

Create marketing materials that emphasize cost savings, environmental benefits as well as product warranties. Digital marketing, taking part in trade shows, and establishing dealer networks will expand your reach.

When you tender for government or institutional contracts, ensure you properly document your credentials, certificates, and past performance records and make them easily accessible.

Step 9: Set Up Distribution and After-Sales Service Network

The reliability of distribution will ensure that the products reach the end-users promptly. Partner with logistics firms that are skilled in handling electronic products.

The development of a solid after-sales service system improves customer satisfaction as well as brand loyalty. Assisting customers with warranty service, quick repairs, and easily accessible helplines are essential.

Working with electricians, retailers and contractors can increase your market reach and encourage repeat sales.

Step 10: Monitor Business Performance and Plan Expansion

Utilize the most important performance indicators, such as production yield, customer feedback, sales growth and return rates to measure the success of your operation.

Utilize data-driven strategies to improve procurement, reduce waste, and improve the design of products.

It is recommended to diversify the product lines, like including smart lighting solutions and expanding to LED component manufacturing, to capitalize on the new market opportunities and sustain the growth.

For more information, check out this video

Overview of the LED Manufacturing Process

The core of your company will be your LED production process. Though it differs based on type of product, the fundamental phases of LED bulb production include:

- Processing of Raw Materials: LED Chips, PCB,s housings, drivers, and other components are purchased and tested.

- PCB Assembly: Utilizing Surface Mount Technology (SMT), components are positioned on PCBs and then soldered.

- Driver Circuit Integration: The constant current driver circuits that control the flow of electricity are in place.

- Assembly of Housing and Diffuser PCB assembly protected by aluminum or plastic casing, with light diffusers.

- Testing: Products are thoroughly tested for lighting and color temperature, as well as power consumption, and for safety.

- Packaging: Lastly, the products are packaged, labeled, and then ready for shipment.

The mastery of this process together with effective quality control, is the foundation of your ability to provide quality products that are competitive and reliable.

Which business to start? How to choose a business idea?

How Niir Project Consultancy Services (NPCS) Supports Entrepreneurs

Niir Project Consultancy Services (NPCS) provides a comprehensive Market Survey cum Detailed Techno-Economic Feasibility Report that equips entrepreneurs with a thorough knowledge of the LED manufacturing environment. The reports contain a thorough analysis of manufacturing processes, raw materials specifications, layouts of the plant, as well as financial forecasts.

Through utilizing the expertise of NPCS, entrepreneurs can evaluate the feasibility of establishing an LED manufacturing plant, determine the most important successful factors and reduce risks, thereby increasing the chances of achieving business success.

Conclusion: Lighting the Path to Industrial Success

The idea of starting an LED lighting manufacturing facility is a forward-looking business idea that blends manufacturing experience in industrial settings with the potential for sustainable, increasing demand. For those who are looking to expand beyond the traditional chemical or pharma areas, this sector provides an opportunity to enter a thriving, driven, innovative, and policy-driven sector.

Follow the step-by-step program outlined here, backed by deep market research, efficiency, the highest quality of operations, quality focus and regulatory compliance, you can create a successful and expandable LED manufacturing business that can meet the demands of India and the international market.