Disposable nitrile gloves have become essential in healthcare, manufacturing, food processing, and many service industries. They are preferred for their strong resistance to punctures and chemicals, especially in areas where cleanliness, safety, and durability are crucial. The recent global health crisis and heightened awareness of workplace safety have led to a sharp increase in demand for nitrile gloves, creating significant investment opportunities for new businesses.

For startups and industrial investors, this sector offers steady demand, expanding uses, and improvements in manufacturing technology. The growing focus on infection control and strict safety guidelines has positioned nitrile gloves as key protective gear, signaling long-term growth potential in this industry.

Market Overview and Growth Potential

The disposable nitrile glove market has expanded significantly over the past decade. During the COVID-19 pandemic, demand spiked to unprecedented levels, and while that surge has stabilized, the long-term demand continues to grow. This ongoing increase is backed by a global focus on hygiene across medical facilities, laboratories, and even in everyday consumer use.

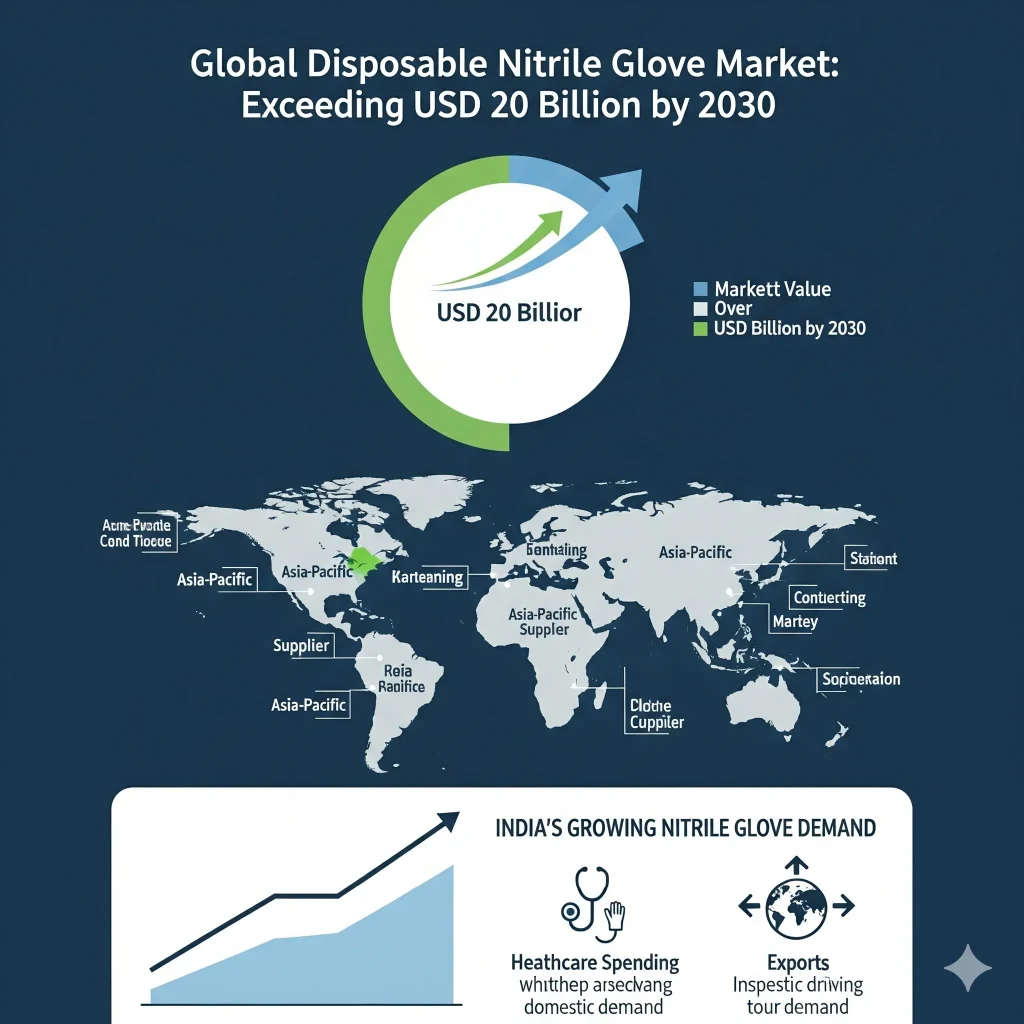

Industry reports estimate that the global disposable nitrile glove market will grow at an annual rate of about 5% to 7% between 2024 and 2030. The Asia-Pacific region, especially India, China, and Malaysia, leads in both production and consumption thanks to cost advantages and easy access to raw materials. North America and Europe also show strong demand due to strict workplace safety and hygiene regulations.

India is becoming an attractive location for nitrile glove manufacturing due to its skilled labor, lower production costs, and proximity to raw material sources. Government initiatives that support healthcare and local manufacturing are further strengthening India’s position in this field.

Detailed project report on Disposable Nitrile Gloves

Demand Drivers in the Disposable Nitrile Gloves Industry

Healthcare and Medical Applications

Hospitals, clinics, and diagnostic labs make up the largest share of demand. Nitrile gloves are favored over latex gloves because they are hypoallergenic and resist a broad range of chemicals and bloodborne pathogens.

Food Processing and Hospitality

In the food industry, nitrile gloves help ensure hygiene, protecting against contamination while handling meat, dairy, baked goods, and ready-to-eat products. Increasing consumer awareness of food safety standards is driving demand in this area.

Industrial and Manufacturing Sectors

From electronics to automotive production, nitrile gloves offer essential protection against solvents, oils, and hazardous materials. Their durability makes them ideal for extended use in industrial settings.

Rising Household and Retail Usage

Post-pandemic, both retail and household usage have surged. Consumers are now using disposable gloves for cleaning, caregiving, and other everyday protective needs.

Global and Indian Market Forecast

Globally, the disposable nitrile glove market is expected to exceed USD 20 billion by 2030, with Asia-Pacific making up the largest portion of supply. In India, domestic demand for nitrile gloves has steadily increased, fueled by rising healthcare spending and exports.

India’s potential as an alternative manufacturing hub to Malaysia, which has historically dominated the glove industry, is attracting new businesses. With favorable government support through initiatives like “Make in India” and increasing export opportunities, Indian entrepreneurs have a promising chance in this sector.

Outline of the Manufacturing Process

The production of disposable nitrile gloves involves multiple stages, combining chemical engineering, material processing, and automated production. Compounding begins with creating nitrile rubber by mixing acrylonitrile and butadiene. Additives such as accelerators, stabilizers, and colorants are included to improve the glove’s properties.

Workers clean and heat ceramic or aluminum hand-shaped molds before dipping them into the nitrile compound. They dip the molds multiple times to achieve the desired glove thickness. Next, they form a bead at the glove’s cuff to strengthen it and make it easier to wear.

Vulcanization then heats the coated molds, linking the nitrile rubber molecules to provide elasticity and durability to the gloves. Leaching and washing are carried out to remove extra chemicals, allergens, and impurities, ensuring the gloves are safe and less likely to cause skin irritation. Curing and drying take place in controlled heating chambers to eliminate moisture and stabilize the final product.

Workers strip and inspect the gloves once they are dried, ensuring strength, elasticity, puncture resistance, and barrier integrity. Manufacturers may add powdering or chlorination to make the gloves easier to put on, though medical regulations have increased demand for powder-free gloves. Finally, companies package and sterilize the gloves for distribution, with medical-grade gloves undergoing additional sterilization.

To explore more, check our books

Challenges and Opportunities for Entrepreneurs

Key Challenges

Raw material availability is uncertain due to fluctuating crude oil prices affecting the supply of nitrile butadiene rubber. High-cost automation is required for advanced dipping lines and inspection systems to ensure product quality. Global competition remains strong as Malaysia, Thailand, and China continue to dominate exports.

Related articles:- Production of Powder-Free Disposable Nitrile Gloves. Startup Business Opportunities in Nitrile Gloves Manufacturing

Opportunities

The growing Indian market benefits from higher healthcare standards and government support for local production. Export potential is rising in Africa, the Middle East, and Latin America, where demand is expanding. Product innovation in eco-friendly, biodegradable, or antimicrobial gloves offers businesses a competitive edge.

Role of Niir Project Consultancy Services (NPCS)

For entrepreneurs thinking about joining the nitrile glove industry, expert guidance is crucial. Niir Project Consultancy Services (NPCS) offers Market Survey cum Detailed Techno Economic Feasibility Reports that provide detailed insights into the industry.

Their reports cover vital areas such as manufacturing processes, raw materials, plant layout, and financial details. By working with NPCS, businesses can confidently evaluate whether to start new operations or expand into new markets.

Future Outlook

The global market for disposable nitrile gloves is set for strong growth in the coming decade, driven by healthcare needs, industrial safety regulations, and changing consumer lifestyles. With the Indian market gaining momentum as a viable hub for both local use and export, there is a strong case for investing in this industry.

Investors can expect ongoing demand, a broad range of applications, and opportunities for innovation in sustainable glove production. While there are challenges related to competition and raw materials, the industry’s potential makes it a resilient and promising venture for the future.

Conclusion

Disposable nitrile gloves are not just protective gear—they are part of a vital industry that connects healthcare, food safety, and industrial safety. The steady demand, positive global growth outlook, and India’s expanding role in this market create ample opportunities for entrepreneurs looking for reliable and profitable business chances. With careful planning, a commitment to quality, and smart market positioning, new businesses can thrive in this industry and achieve long-term success.

By leveraging resources like NPCS and staying in tune with global trends, entrepreneurs can confidently enter the nitrile glove manufacturing sector and help create a safer, more hygienic world.

Discover the best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What makes disposable nitrile gloves a good investment?

Disposable nitrile gloves are a great investment due to their versatility and high demand across various industries. They are essential for protecting against chemicals, punctures, and viruses, making them vital in healthcare, food service, and manufacturing. The increasing emphasis on hygiene and safety, particularly after events like the COVID-19 pandemic, has further driven their demand.

What are the potential risks of investing in disposable nitrile gloves?

Potential risks include intense market competition, especially from manufacturers in Southeast Asia, and price volatility influenced by raw material costs, primarily acrylonitrile butadiene rubber. Additionally, changes in regulatory standards or a decrease in demand for personal protective equipment (PPE) could impact profitability.

How can one start an investment in this sector?

You can invest by manufacturing the gloves yourself, importing and distributing them, or investing in a company that already operates in this space. Manufacturing requires significant capital for machinery and raw materials, while importing and distribution can be less capital-intensive but rely heavily on establishing reliable supply chains.

What are the key factors to consider before investing?

Before investing, you should evaluate the target market (e.g., healthcare, industrial), regulatory compliance (e.g., FDA or European standards), supply chain logistics, and market trends to ensure a sustainable business model. Understanding these factors will help you make a more informed decision and mitigate risks.

Is the demand for nitrile gloves sustainable in the long term?

Yes, the demand for nitrile gloves is expected to be sustainable. While pandemic-related demand may have peaked, the long-term trend towards greater health and safety consciousness in all sectors, along with growth in industries like healthcare and food processing, suggests that the market will remain robust. The market will remain robust.