Industrial packing is a key component of India’s rapidly evolving industrial economy. HDPE Barrels are used for storing and transporting hazardous chemicals, lubricants, and oils, as well as agrochemicals. Triple-layer HDPE blow-moulded barrels are a popular packaging solution because of their structural integrity, improved performance, and ability to comply with regulatory packaging standards.

For manufacturers and industrialists of the new age, investing in triple-layer HDPE barrel blow moulding plants is an opportunity not only to tap into a rapidly growing domestic market but also to service global markets, which are actively replacing heavy metal drums with lightweight and durable polymer alternatives. This guide offers a technical and market-driven perspective on feasibility to help you create a future-proofed business in this niche but powerful domain.

Understanding the rising demand for triple-layer HDPE barrels

Multi-layer packaging is becoming more popular due to the growing need for durable packaging that can withstand external contamination and long-term durability. Triple-layer barrels have become increasingly popular because they provide several advantages that single-layer containers can’t match.

The inner layer is made from virgin HDPE. This ensures that the barrel can safely store sensitive substances and is chemically inert. The middle layer is usually made of reprocessed HDPE to reduce cost and impact on the environment. The outermost layer has been designed to provide strength, UV protection and branding. This structure strengthens the barrel, but also improves its shelf appeal. It protects the content from light and atmospheric degradation.

The packaging is standard across multiple industries, from specialty chemicals to lubricants, pharmaceuticals and agro-inputs. Storage conditions and safety compliance cannot be compromised. Triple-layer barrel production has become a popular venture among startups and small businesses due to its reliability, scalability and sustainability.

Related: Smart Manufacturing of HDPE Barrels: Why Triple-Layer Blow Moulding Is the Future

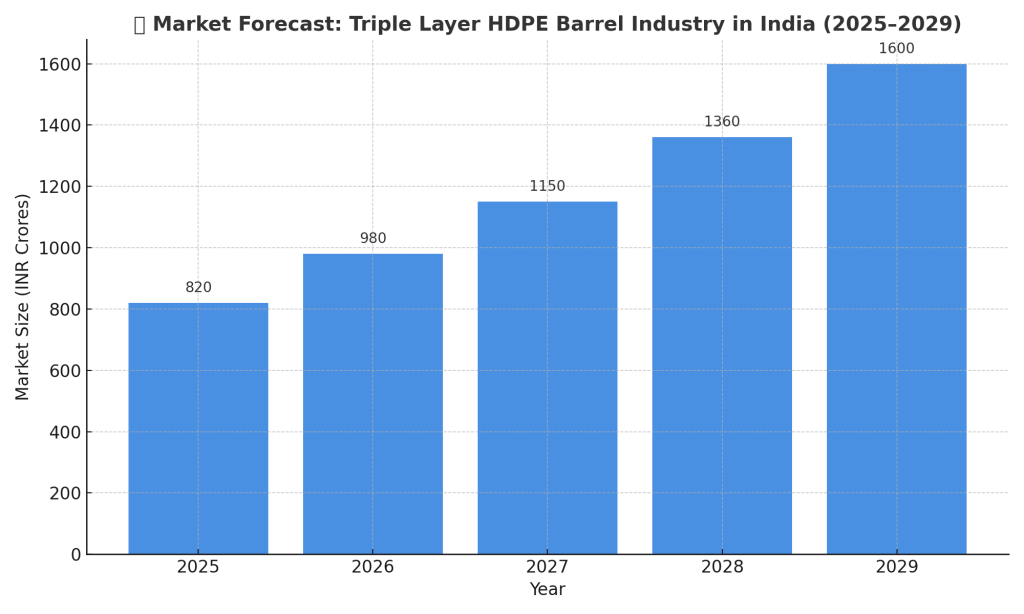

Market Potential and Industry Forecast

The industrial packaging industry in India has experienced a remarkable rise over the last decade. This growth was fueled by an expanding export market, increased chemical production and rising agrochemical use. The market for HDPE in India will be worth Rs 3,500 crore by 2025. It is expected to grow at an annual compound growth rate of 15% over the next 5 years.

Demand is influenced by several macroeconomic trends. India’s chemical industry is expected to grow by $300 billion in 2030. This growth will be driven by domestic consumption and exports. The “Make in India’ initiative of the Indian government has led to an increase in local production for goods that require durable bulk packaging. Third, the increasing restrictions on metal drums due to weight and rusting have led to a shift towards polymer alternatives.

The market for triple-layer HDPE cannisters is expected to reach Rs 7,000 crore between 2025 and 2030. Due to the global trend towards sustainability and lightweight logistics Indian manufacturers now export these barrels to African, Southeast Asia and Middle Eastern markets, all of which have rapid industrial growth.

Applications across Key Industries

Triple-layer HDPE Barrels are used in a variety of industries, including those that require long-term storage and transportation safety, as well as regulatory compliance. They are used in the sector to package liquid pesticides and herbicides. UV resistance and chemical compatibility are important. Pharmaceutical manufacturers use these barrels to store base chemicals and active substances, taking advantage of their airtight seal and contamination resistance. Food-processing companies use these barrels to store edible oils, food flavors, and syrups because of the hygienic interior layer made from virgin HDPE.

Lubricants and the Automotive Oil Industry use 210-litre containers as the standard industry size for the supply of products to factories and service stations. Triple-layer barrels are now being used by waste management companies due to their long shelf life and leak-proof design. They allow for the safe transport of liquid industrial waste.

This barrel format is an essential component of modern B2B packaging and logistics systems due to its versatility, safety and durability.

The Step-by-Step Production Process of Triple Layer HDPE Barrels

To set up a triple-layer barrel plant, you will need to master a sophisticated version of the blow moulding technique. This is a method that creates hollow plastic parts by inflating molten plastic into a mould cavity. Triple-layer barrels are made using coextrusion. Three distinct layers of material is simultaneously processed and layered into a composite parison.

The first step is to feed the raw materials separately into three different extruders. The co-extrusion system is fed with virgin HDPE and reprocessed HDPE. UV-resistant HDPE (or masterbatch) or UV-resistant HDPE are also directed there. The materials are then melted and homogenized before being fed into the diehead, which combines them into a three-layer parison. This step requires precision control, since any variations in the wall thickness could compromise barrel performance and safety.

After the parison has been formed, the material is placed in a two-part mold and compressed air is used to blow it into the shape of the mould — which is usually a 210-litre cylinder. The barrel is then hardened by cooling systems, which reduce the temperature in the mould. Trimming machines remove excess plastic at the top and bottom of the barrel, giving it a neat and finished look.

As part of the quality control process, each barrel is tested for leaks, dropped, and weighed. The barrels are then labeled or printed according to the client’s branding requirements and stacked before dispatch.

Related: HDPE Jumbo Bags Manufacturing Industry

Core Machinery and Plant Overview

For a triple-layer HDPE barrel production plant, a combination of high-performance machines is required. This starts with a blow moulding machine which supports multi-layer dieheads. The machine’s size and configuration will depend on how much output you want. Small plants can aim to produce 500 barrels per day, while large operations can reach 2,000.

Each set-up includes raw material feeders and dosing/mixing units, barrel specific moulds and hydraulic systems. It also includes cooling towers and air compressors. Automation can be implemented at different levels, especially for leak testing, trimming and packing, to improve efficiency and reduce the need for manual labor.

The modern plants include units for recycling, which process defective and trimming products and reuse them in the middle layer. This increases sustainability and efficiency.

Quality Control and Regulatory Compliance

The production of triple-layer barrels is critical to quality assurance, as they are used for storing sensitive or hazardous materials. Indian Standard is 6312 must be adhered to as a minimum requirement. Manufacturers who want to provide services to international clients are often required to comply with UN/DOT transportation certifications when packaging dangerous goods.

Manufacturers must also conduct regular chemical resistance and permeability testing. Most buyers, especially in the pharmaceutical and agrochemical industries, conduct third-party audits. They also require ISO certifications, including ISO 9001 and ISO 14001.

The plant personnel should be educated on the importance of quality documentation and traceability, particularly when barrels will be used for exports or substances that are regulated.

Export Potential and Strategic Location

The export potential of triple-layer HDPE is growing rapidly, especially in Africa, Gulf countries, Southeast Asia, and Latin America. Emerging markets such as Kenya and South Africa, UAE, Bangladesh, and Sri Lanka are growing their demand for durable, cost-effective packaging.

The logistical advantage of locating the factory in or near industrial clusters such as Gujarat or Maharashtra or Tamil Nadu, or Telangana is significant. These regions are not only close to chemical and agricultural hubs, but they also offer established infrastructure, port connectivity and access to skilled technical labor.

Sustainability and Environmental Responsibility

Triple-layer technology has been designed to be sustainable. Recycled HDPE is used in the middle layer to reduce environmental impact without compromising quality. Several plants are now incorporating post-consumer waste into their reprocessed HDPE under safe standards. The outer and interior layers are made of virgin polymers to ensure product integrity. However, the overall design reduces the material-to-volume ratio and makes it a lightweight, resource-efficient option.

The barrels can be reused, and they are recyclable at the end of their life cycle, which adds layer of compliance with environmental regulations. Triple-layer barrels are becoming more popular in industrial supply chains as India tightens up its Extended Producer Responsibilities (EPR) regulations.

For more information, check related videos here

How NPCS can support your industrial setup journey

A manufacturing venture is more than just machinery. It requires a detailed feasibility study, technical plan, and market validation. Niir Project Consultancy Services (NPCS) is a key partner in this process.

NPCS produces Market Reports cum Detailed Techno-Economic Feasibility Reports which cover all aspects — from manufacturing processes, raw materials and plant layouts to financials and marketing channels. Entrepreneurs depend on NPCS for assessing the commercial and technical viability when setting up new industrial projects.

Whether you are looking for clarity on plant capacities, raw material procurement or market positioning, NPCS provides actionable insights backed by research that will reduce risk and improve execution.

Which business to start? How to choose a business idea?

Final Thoughts

India’s position as a global manufacturing center will only increase the opportunities for industrial packaging. Start a triple-layer HDPE barrel blow-moulding plant to become a key player in the chemical and pharmaceutical industries, as well as the agro-food, logistics, and agro-processing ecosystems.

Entrepreneurs can create scalable ventures, which serve domestic and international markets, by focusing on quality products, regulatory compliance and sustainable manufacturing. This sector can generate robust returns by addressing industrial needs with the help of NPCS and a solid understanding of market dynamics.

Triple-layer HDPE barrels could be the next big leap in your industrial career if you are looking for a manufacturing venture that is high-demand and low-waste with an export focus.