Glass fiber reinforced concrete (GFRC) also known as glass fiber reinforced concrete or GRC is a type of fiber-reinforced concrete. GFRC is made up of a combination of cement, polymer, fine sand, and water. GFRC comes up with good strength, weight, and design, because of this GFRC is used for a variety of applications. GFRC is quite versatile. Most of the time GFRC is used for construction purposes. Exterior building façade panels and architectural precast concrete are the places where Glass fiber reinforced concrete is used. GFRC has been used by concrete artisans for fireplace surrounds and other decorative panels. It’s used for aesthetic purposes as well as some parts of interior furniture like GFRC coffee tables. GFRC comes with the ability to construct lightweight panels using it.

GFRC comes up with these two properties mainly:

- High Tensile Strength: High dose of glass fibers gives GFRC high tensile strength.

- Flexible: High polymer content makes GFRC flexible.

Start a Business in Construction Industry, Click Here

Opportunities for Glass Fiber Reinforced Concrete (GFRC) Manufacturing Industry:

GFRC product is expected to grow at a CAGR of 5.76% in the next seven years. Rapid urbanization, along with the growing population and changing lifestyle among the people has led to an increase in construction projects especially in developing countries like India and China. Other developing regions like Latin America and the Middle East also serve as a polestar for the construction industry. Rapid industrialization has led to rapid construction in these regions.

With an increase in the GDP of these regions. There has been a surge in the opportunities concerning construction. Glass Fiber Reinforced Concrete (GFRC) is in demand and the opportunities in the manufacturing of GFRC have been increasing day by day.

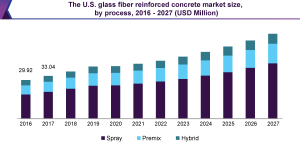

Demand for glass fiber in civil constructions, and commercial and residential purposes is increasing. The rise in the construction of single homes is going to serve as a major factor for fueling the GFRC product. Due to the rise in renovation projects, the product in the U.S is projected to show higher growth. The increase in technological advancements along with the benefits of low cost and easy installation of precast concrete have propelled the GFRC product.

Global GFRC manufacturers are also involved in research and development related to the production of fiber in different sizes with different properties. The growing tourism industry has boosted the demand for resorts and restaurants thus opening more opportunities for GFRC manufacturers. The properties of GFRC including its being eco-friendly and lightweight make GFRC ideal for landscaping. GFRC can be modeled in complicated forms.

Related Business Plan: Glass Reinforced Concrete (grc)

Project Report on Materials:

The project demonstrates the whole set of historical facts, earnings, and essential advancements, as well as the critical policies proclaimed by key institutions catering to the project. This provides dynamic and in-depth perspectives in aim to exhibit the current state of the worldwide product.

The purpose of the material report is to assist and advise a business owner in gathering reliable information on the project’s material requirements. It contains crucial information such as raw material requirements, machinery descriptions, and manufacturing methods within the factory. The report covers plant capacity, project setup costs, operational capital requirements, estimated sales, and profit.

Related Feasibility Study Reports: Concrete, Cement and Cement based Products and Projects

Our Strategy:

- Our research papers cover Indian products in general, including current analysis, outlook, and forecasts.

- Secondary research is used to produce product projections, which are then cross-validated through interactions with industry participants.

- We rely on trusted data sources and databases. We process information from these sources and include it in the report.

Pre-Feasibility Study Report includes the following items:

NPCS did study on GFRC product dynamics, including industry growth drivers, difficult conditions, opportunities, risk, limitations, and dangers. The pre-feasibility research also includes a production value analysis, which includes raw material analysis, product fee trend, Mergers & Acquisitions, growth, key product suppliers, GFRC product place awareness charge, and manufacturing process analysis. In order to assist startups and entrepreneurs, the study also provides a product result characteristics analysis that focuses on technical advancement, consumer demand patterns, and external environmental exchange.

Read Similar Articles: Construction & Building Materials Projects

For each of the product segments, the research offers a critical product analysis. A cost chain analysis provides detailed information on value generation at each level. The pre-feasibility research looks at the drivers and limits of the GFRC product, as well as their impact on demand during the projection period.

The research also goes over all of the important variables that a company should think about before entering the GFRC industry. It is completely based on current financial data and includes extensive information on the primary method flow, raw material needs, reactions, application costs, working fees, capital investments, predictions, and margins, among other things. Entrepreneurs, researchers, professionals, commercial business strategists, and everyone else interested in the GFRC industry should study this text. The study also looks at the main GFRC manufacturers’ sales, value, product share, and future development plans. The sales, duration, quality, and estimates of the product are all mentioned.

Read our Book Here: The Complete Book on Cement & Concrete Products Manufacturing

Latest Product Trends of Glass Fiber Reinforced Concrete (GFRC) Industry:

There has been thus exceptional growth in the GFRC sector owing to the key investment in airport construction in the last few years in the Asia Pacific and Middle-East regions. Owing to a growing population and the increase in middle-class incomes, the growing construction industry has driven the demand for hotels, stadiums, and other buildings. This has accelerated the demand for GFRC.

The efforts of the government towards residential construction are likely to fuel the global GFRC product. Asia Pacific region is expected to grow at its highest rate at a CAGR of 6.6% in the next 6 years. Construction Companies are increasing in the Asia Pacific region and the collaborations with fiber-reinforced concrete manufacturing companies have further led to an increase in the product growth of GFRC.

Watch Video: Glass Reinforced Concrete (GRC) | Production of GRC or GFRC.

Report on the Advantages of Using Our GFRC Project:

Product research provides information to explore product potentials for products and services for expansion of any enterprise/business. Product research and analysis helps extensively to formulate their policies and Promotional Program, Regional Development and Project Financing, Product Strategy, Impact of Globalization and Product Specification. We have prepared approx. Product Surveys on various subjects which are prepared by our expert panels, researchers, analyzers and consultant engineers based on professional research and analysis on global and regional product for small and medium enterprises all the reports are based on product study from secondary sources.

Through our network of professional consultants, we undertake the Product research that elucidates the present product potential as well as future scope of the product. Investor needs to rely on product research /Reports to analyze present Product Position, Expected Future Demand to formulate their policies and programs. We also provide statistics of Imports & Exports, Exports Prospects, Names and Addresses of Existing Units and many more details. The product research is highly focused and extensive in nature.

The worldwide GFRC product is fiercely competitive, and the sector faces considerable entry barriers due to high start-up costs and government restrictions. The project report assesses the present state of the worldwide product, current trends and drivers, as well as the overall product environment. The researcher’s in-depth vendor study aims to assist clients in improving their product function, and this project report follows suit by giving a comprehensive analysis of a number of important GFRC product places.

Read our Books Here: Cement, Asbestos, Ceramics, Bricks, Limestone and Construction Materials Manufacturing Technology

What Is the Manufacturing Process of Glass Fiber Reinforced Concrete (GFRC)?

There are mainly three methods involved in the manufacturing of Glass Fiber Reinforced Concrete (GFRC):

- Traditional hand spray-up

In this method, GFRC is hand-sprayed into a mold. A concentric chopper gun is used along with hand spray which is fed by a spool of GFRC roving pulled into the gun which is then mixed in the nozzle.

Experienced workers along with expensive equipment are required in this case.

Using a drywall hopper gun, the face coat is sprayed into the mold.

Then the GFRC baker coat is placed either by pouring the layer or by troweling it on using hand.

The GFRC layer is then compacted with the help of rollers. Shear has to be provided using mixers for GFRC. GFRC sets quickly with the help of polymer addition. After this, the panels can be stripped and later polished.

- Vibration casting

This is a simpler method and requires water-tight molds. Premixed GFRC is flooded into a mold which is then vibrated.

- Sprayed premix

This method doesn’t require less expertise in comparison to the hand spray-up method. In this method Sprayed premixed GFRC along with chopped fibers are used. A pump and a spray head are also used.

Glass Fiber Reinforced Concrete (GFRC) Manufacturing Industry FAQs:

- What is a major driver in the Glass Fiber Reinforced Concrete (GFRC) product?

The increase in the adoption of green buildings is a major driver in the Glass Fiber Reinforced Concrete (GFRC) product.

- Which are the top companies in the Glass Fiber Reinforced Concrete (GFRC) product?

The key players in the Glass Fiber Reinforced Concrete Product include:

- Fibrex Construction Group

- Clark Pacific

- Ultratech Cement Ltd.

- Low & Bonar

- Formglas Products Ltd.

- BB Fiberation

- What is the growth rate of the global Glass Fiber Reinforced Concrete (GFRC) product?

The Glass Fiber Reinforced Concrete (GFRC) product is projected to grow at a CAGR of 9% over the next five years.

- Which region has the highest growth rate in the global Glass Fiber Reinforced Concrete (GFRC) product?

The Asia Pacific is growing at the highest rate.

Watch other Informative Videos: Construction & Building Materials Projects

Conclusion:

Our Detailed Project Report seeks to provide all of the necessary information for any entrepreneur considering a project. Entrepreneurs are sometimes faced with the challenge of deciding on a suitable product/line while expanding an existing firm or starting a new one. NPCS also publishes a variety of process technology, technical, reference, self-employment, and startup books, a directory, business and industry database, bankable detailed project report, product research report on various industries, small scale industry, and profit-making business, as well as a directory, business and industry database, bankable detailed project report, product research report on various industries, small scale industry, and profit-making business.

See More Links:

Start a Business in Potential Countries for Doing Business

Best Industry for Doing Business

Business Ideas with Low, Medium & High Investment

Looking for Most Demandable Business Ideas for Startups

Start a Business in Middle East

DD_Art2022