In its liquid, fresh form, milk is an excellent source of nutrition. What happens when the creamy goodness is transformed into a fine white powder? What happens when this creamy goodness transforms into a fine, white powder?

Why Dry Liquid Milk?

Powdered milk is a great way to overcome these limitations. Powdered Milk is a solution to these problems. It reduces the amount of water in the milk, which inhibits the growth of bacteria.

The journey begins: from fresh milk to processing

Powdered milk is made from high-quality, fresh milk that comes from cows. It goes through several steps to ensure purity and prepare it for drying.

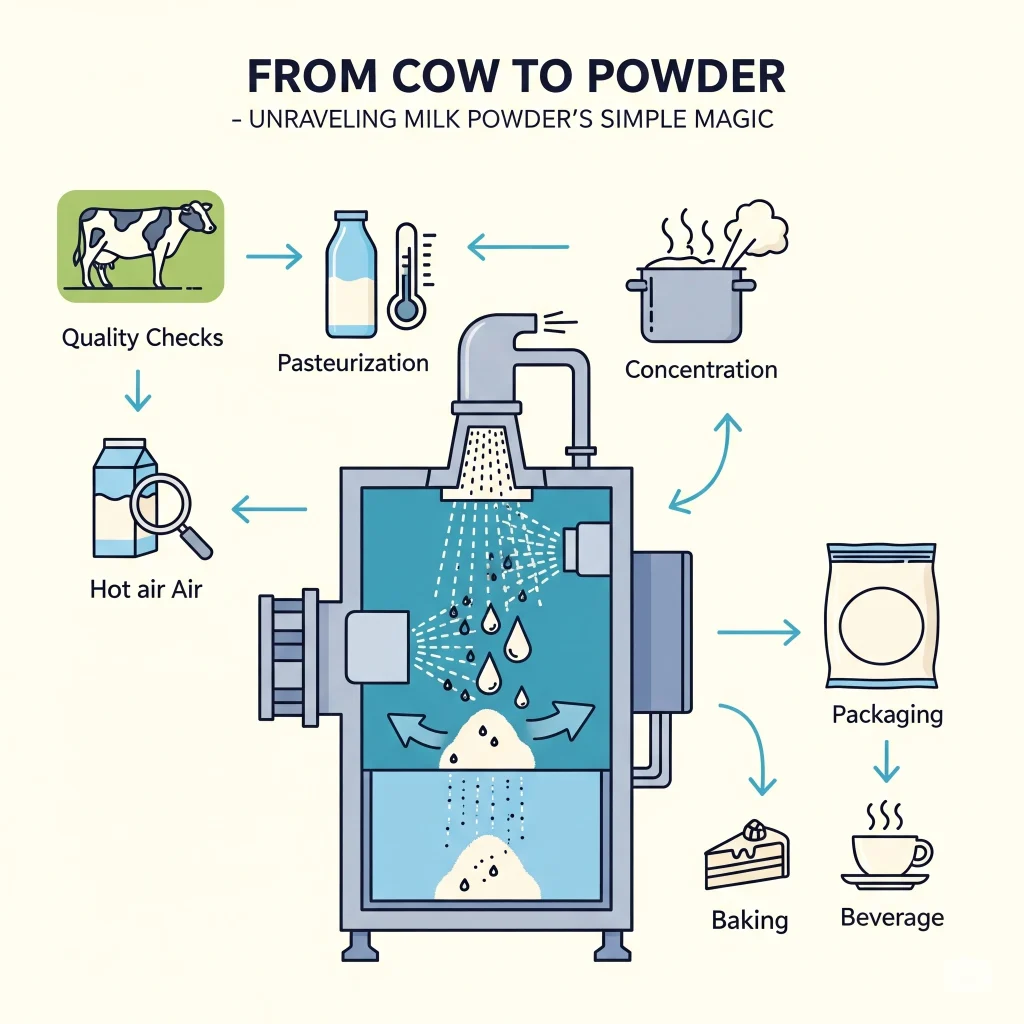

- Quality Checks and Collection: Powdered milk starts with high-quality, fresh milk sourced from cows. Workers collect the milk and transport it in refrigerated tanks to the processing facility, keeping it cold to prevent spoilage. Upon arrival, they perform a series of quality tests, checking for contaminants, fat content, and protein levels. Only milk that passes these tests goes on to become powdered milk.

- Standardization: Since milk’s fat content naturally varies, technicians adjust it to a specific level for most powdered milks. They separate the cream, then add back just the right amount to reach the desired percentage. For skim milk powder, they remove almost all of the fat.

- Pasteurization: Technicians heat the milk for a set period and then cool it rapidly, ensuring safety without sacrificing flavor or nutrition. They use either High-Temperature Short Time (HTST), heating the milk to 72°C for 15 seconds, or Ultra-High Temperature (UHT), heating it between 135–150°C for a few seconds.

- Concentration: Finally, they concentrate the pasteurized milk before drying to reduce water content. This step makes the drying process more energy efficient. Workers typically use vacuum evaporation at low temperatures to preserve the milk’s quality.

Read More: 5 High Profitable Business Ideas in Dairy production, Milk Processing and Dairy Products Industry

The heart of the process: drying the milk

Spray drying is the most common method due to the higher quality of the powder produced. The more common method is spray drying due to its higher quality powder.

Spray Drying: A Fine Mist Into Dry Powder

This continuous process quickly turns milk into fine powder.

- Atomization The milk is atomized using spinning disks or high-pressure nozzles to create a fine mist. The liquid is dried faster because the surface area increases.

- Drying With Hot Air: A stream of hot dry air is simultaneously blown into the chamber. This hot air comes in contact with a fine mist of droplets of milk. Its high temperature provides the energy required to evaporate the moisture from the droplets.

- Separation Powder: The milk solids evaporate and are left as fine powder particles. They are separated from the moist atmosphere using bag filters or cyclones located at the outlet to the drying chamber. The dried milk powder collects at the bottom.

- Packaging and Cooling: The milk powder collected is cooled in order to maintain quality and prevent clumping. It is then packaged in airtight cans or bags, and often under nitrogen atmosphere, to extend the shelf life of the product.

Spray drying is popular because it is quick and exposes milk to high temperature for a short time, preserving its color, flavor and nutritional value.

Read Our Book: Modern Technology Of Milk Processing & Dairy Products (4th Edition)

Roll Drying: A thin film to dry Flakes

Drum drying is a method of drying powdered milk that has been used for many years. The process involves:

- Application of Heated Rollers A thin film of concentrated milk is applied to the heated rollers.

- Surface Drying: The thin film of milk quickly dries due to the heat generated by the drum surface. This process takes only a few moments.

- Grinding and Scraping: After the milk film has dried, it can be scraped from the rotating drum using knives or scrapers. The milk solids will then be conveyed to the next stage of processing.

- Grinding & Packaging: To achieve a uniform consistency, the dried flakes can be ground into powder. This powder is then cooled down and packaged in airtight containers similar to spray-dried powdered milk.

Roller drying is less expensive than spray-drying, but it can lead to a change in the flavor of the milk and a reduction in its solubility. The flavor of roller-dried powdered milk may be slightly cooked.

Read More: Profitable Dairy Farming: A Lucrative Startup Opportunity

Post-Drying Treatment Enhances Quality and Function

The powdered milk can be further treated to enhance its properties after the primary drying process.

- Instantization Some powders of milk are instantized in order to make them dissolve more quickly and easily when placed in cold water. Typically, this process involves rewetting powder particles in order to produce larger and more porous agglomerates which disperse more easily. The agglomerates created are gently dried.

- Lecithination Some instant milk powders contain a small amount (emulsifier), which is added on the surface of powder particles. Lecithin improves the wettability of the powder and its dispersibility by allowing water to penetrate it more easily.

Read Our Detailed Project Report Focused On Various Forms Of Milk Powder

The final product: Versatility and versatility in powder form

Powdered milk retains the majority of the nutrients of fresh milk including calcium, vitamin D, protein and other minerals. However, the exact nutritional profile will vary depending on whether it is whole milk or skim milk and how the milk was processed.

Powdered Milk is an ingredient that has many uses.

- Household use: This liquid milk can be reconstituted easily with water for cooking and baking.

- Food Industry: It’s widely used in a variety of food products such as processed foods, yogurt, cheese, infant formulas and baked goods.

- Prepare for an Emergency: Due to its long shelf-life, it is essential in emergency food and aid packages.

- Travel Activities and Outdoor Activities: A lightweight, convenient alternative for those who travel, camp, or hike and may not be able to access fresh milk.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion: The simple ingenuity behind dried milk

Powdered milk is made by spray-drying fine droplets of liquid or roller-drying a thin, stable film. This process is an example of ingenious food preservation. Powdered milk is made by removing the water from a perishable liquid and transforming it into a versatile and nutritious powder.

How is Powdered Milk Made: FAQs (Frequently Asked Questions)

Q1 : Is powdered Milk as Nutritious as Fresh Milk?

A : Yes. Powdered milk has most of the nutrition of fresh milk including calcium, protein and vitamins.

Q2 What is the shelf-life of powdered or dry milk?

A. Powdered or dry milk can be stored for up to 10 years if it is kept in a dry, cool place. Whole milk powder typically has a shelf life of 6-18 months due to the fat content.

Q3 How do I reconstitute milk powder?

A You mix powdered water with it to reconstitute milk powder. For nonfat dry milk, it is recommended that you mix 1/4 cup powder with 1 cup water. The ratio for whole milk powder may vary depending on the desired amount of fat and the instructions provided by the manufacturer. For better dissolution, it’s best to use lukewarm or cool water.

Q4 Can powdered dairy be used for baking or cooking?

Yes. Powdered milk can be used to enhance the taste, texture and nutritional value of many dishes.

Q5 – Does powdered Milk taste the same as fresh Milk?

A : Reconstituted powdered Milk can have a variety of tastes depending on the milk quality and the method of processing. Spray-dried powdered milk has a taste that is closer to fresh milk compared to roller-dried powdered milk, which can have a slightly cooked flavor.

Q6. Are there different types powdered milks?

A The main types of nonfat dry milk are skim milk powder (skim) and whole milk, which is a powder that contains fat. Other specialized types include buttermilk powder and other dairy byproducts like whey.