Compostable, disposable tableware is at the intersection of convenience and accountability. As consumers, restaurants, caterers, and event planners push for plastic-free, single-use products, manufacturers who provide compostable alternatives will find steady, long-term demand.

These products service foodservice chains, quick-service restaurants, grocery delis, institutional cafeterias, and retail consumers generating reoccurring sales and a scalable manufacturing path. And with policymakers tightening requirements around single-use plastics and buyer preference changes, compostable food service ware is a strong, evergreen opportunity for start–ups and entrepreneurs.

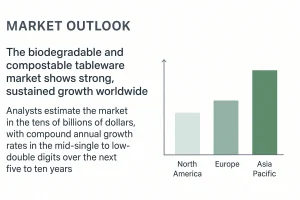

Market outlook: size forecast, and what to be ready for

The global biodegradable, compostable tableware market is strong and steady growth. Analysts report that the market is worth tens of billions of dollars, and expect the compound annual growth rate over the next five to ten years to be in the mid-single to low-double digits.

Detailed Project Report on Compostable & Disposable Tableware

Drivers of Demand and Market Segments

A number of durable trends continue to drive demand. Food delivery and takeaway services are increasing usage of single-use tableware. Corporate sustainability commitments and retailer sourcing policies push consumers toward certified compostable products.

Local and national bans on polystyrene and certain plastics are creating very clear substitution demand. Product innovation—greater grease resistance, better heat tolerance, and higher quality printing—are expanding uses into events and elevated catering. Collectively, these trends create a multi-channel market sweetheart for manufacturers that can produce at scale with higher and consistent quality.

Key Products and Materials

Key product categories include plates and trays, bowls, hot and cold beverage cups, cutlery, serving containers, clamshells, and lids. Common materials include sugarcane bagasse, bamboo, molded fiber, palm leaf, coated paperboard, and PLA bioplastics. Each material has trade-offs in heat and grease resistance, certification, compostability performance, and complexity of processing. A strong material-to-market fit is critical part of a durable manufacturing business.

Want to learn more? Visit our books

Selecting the Appropriate Product Mix: Strategic Factors

The decision for product lines will likely involve analysis of local levels of demand as well as raw material accessibility , the amount of technical difficulty in producing, and certification requirements. For example, bagasse plates or molded-fiber bowls will typically require less complex conversion machinery and remain appropriate product lines for food service operators with limited disposable budget, such as, a cafeteria, deli, or casual dining.

PLA cups and coated paperboard items will demand more stringent processing controls and will also likely require coordination along the supply chain, but also these products can harvest higher prices in some market areas. Wooden or bamboo utensils may also be developed for the premium events market, or even retail applications. The practical advice for a launch perceivable stragery would be to select one or two established and reliable product lines and expand into higher-profile and higher–margin products later.

General Process Flow of Manufacturing

The majority of compostable tableware producers face a replicated and organized process flow that ultimately can assist an entrepreneur in laddering up its operations.

Product specification and formulation

Consideration of product length, thickness, compostable standard and functionality of the product (i.e. heat resistance, grease resistance, etc.). In developing product specifications, having the specifications clear will enable repeatable manufacturing.

Raw Material Source and Preprocessing.

Shaping and Molding

For bagasse and molded fiber, wet pulp can be formed to shape in molds, and then further shaped and solidified by heat–pressing. For PLA and coated paperboard, the process is thermoforming, extruding, and precision cutting for cups and lids.

Drying, Curing , and Finishing

When processing, remove residual moisture, trim flash, and smooth the surfaces. Where liquid–tightness is a requirement, apply approved compostable coatings, or heat seal layers.

In–Process Quality Control

As you are running continuous production, test thickness, dimensions, leak–resistance, compostability indicators like testing for BPI compliance so any deviations can be addressed quickly.

Printing, Branding, and Packaging

Most buyers want their logo on prints, or custom home branded sleeves. Use water-based, biodegradable inks in both design and branding, and use packaging designs that will protect the products in transit.

Final QC and Certification Review

Ensure you are conducting batch testing during production, have a tracking system for your product‘s, and keep records of any certifications in compliance with compostability and food contact standards.

Warehousing and Distribution

Fall–on stage could be inverse to production...that is store in a warehouse where finished goods are kept in dry, temperature stable environments to be shipped to distributors, restaurant chains, or retailers on a replenishment schedule.

Quality, certification, and compliance — non-negotiables

Buyers and composting facilities expect credible certifications and clear labeling. Achieve recognized industrial compostable standards and meet food-contact safety rules. Maintain technical data sheets, batch traceability, and third-party test reports. Transparent certification prevents product rejection at composting facilities and protects your reputation in a market that increasingly demands verified sustainability claims.

Operations: raw-material resilience and supply-chain strategy

Secure multiple raw-material suppliers and aim for local feedstock clusters to cut transportation risk. For bagasse, proximity to sugar mills improves freshness; for bamboo and wood, ensure sustainable harvesting and traceability.

For PLA and specialty compostable polymers, establish reliable resin import or domestic compounding channels. Negotiate steady offtake agreements with caterers or retailers to stabilize production. Keep smart inventory buffers and work with logistics partners experienced in high-volume, lightweight goods to shorten lead times and reduce service failures.

Sales channels and go-to-market approach

Target the buyers who drive volume early: foodservice distributors, national quick-service chains, event organizers, and supermarket chains. Combine direct selling to caterers, co-packing for meal kits, and distributor partnerships to reach smaller retail outlets. Offer branded packaging and service-level agreements to lock in repeat orders. In B2B manufacturing, consistent quality and reliability often beat low price when procurement teams make long-term supplier choices.

Sustainability economics and circularity

Compostable tableware only achieves environmental value if appropriate composting infrastructure exists. Advocate with municipalities and waste haulers, include clear disposal instructions on packaging, and run pilot take-back programs with large customers.

Work with waste-management partners so buyers can see composting work locally. When procurement teams witness real circularity, they are more likely to budget for and buy compostable products. Embed lifecycle thinking in product design and buyer education to stand out in crowded markets.

Related articles:- Major Trends Shaping the Biodegradable Tableware Sector

Risk factors and mitigation

Watch raw-material price swings, certification gaps, greenwashing claims, and competition from cheaper non-compostable alternatives. Mitigate these risks by diversifying inputs, maintaining transparent certification and testing, investing in robust quality systems, and documenting end-of-life pathways clearly for buyers. If local composting infrastructure lags, target markets with better waste handling or focus on home-compostable products where appropriate.

Scaling and diversification

After you secure reliable production and anchor accounts, scale by adding SKUs, enhancing printing and branding, or introducing complementary items such as compostable lids. Geographic replication — opening a second plant closer to a new demand hub — cuts distribution costs and shortens lead times for national customers.

NPCS — a useful resource for entrepreneurs

Niir Project Consultancy Services (NPCS) prepares Market Survey cum Detailed Techno Economic Feasibility Reports to help entrepreneurs evaluate compostable tableware and related opportunities. Their reports include manufacturing process details, raw-materials lists, plant layout recommendations, and financial projections. NPCS helps entrepreneurs assess the feasibility of setting up new industries or businesses and supports informed decision-making.

Conclusion: build reliability, not just novelty

Compostable and disposable tableware becomes an evergreen manufacturing category when you pair the right material choices with rigorous quality, credible certification, and focused sales channels.

The market will keep expanding as foodservice volumes rise, regulators restrict single-use plastics, and consumers demand sustainable choices. For entrepreneurs, success rests on executing repeatable production, securing resilient raw materials, and proving that products actually compost in the real world.

Focus on consistent delivery, verified sustainability claims, and excellent customer service, and you can build a durable, scalable manufacturing business that meets both market demand and environmental expectations.

Find the best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What exactly is compostable tableware?

Compostable tableware is single-use foodservice items made from materials that break down into natural elements under industrial or home-composting conditions, leaving no toxic residues. Common examples include plates, bowls, cups, and cutlery made from bagasse, molded fiber, bamboo, palm leaf, and certain bioplastics.

How is compostable different from biodegradable or recyclable?

“Biodegradable” means a material can break down naturally over time, but does not guarantee safe or complete decomposition. “Compostable” means the item meets specific standards for breaking down into harmless organic matter in a defined composting environment. “Recyclable” means the material can re-enter the production stream — many compostable materials are not recyclable in standard recycling systems.

Which certifications should manufacturers aim for?

Manufacturers should target recognized standards such as ASTM D6400 or EN 13432 for industrial compostability and any relevant local compostable standards. Food-contact safety tests and third-party lab reports also help buyers trust your claims.

Can compostable tableware handle hot and greasy foods?

Yes. Many compostable materials (like properly processed bagasse, coated paperboard, and some PLA blends) can handle hot and greasy foods when manufactured and finished correctly. Always validate heat and grease resistance through in-process testing and customer trials.

Is industrial composting required, or will items break down at home?

Some products require industrial composting due to higher temperatures and controlled conditions; others are designed for home composting. Label products clearly so users and waste managers know the correct disposal route.