Engineers convert long chains of glucose molecules into useful materials. Cellulose fiber is made from the chains that plants create. In this article I describe what cellulose fiber is like on a molecular scale, where it comes from, how it’s made into fibers by plants and factories (from flax and cotton to viscose and nanocellulose) and how it can be used in products. This article is written in an active voice with step-by-step detail, tables, and clear paragraphs to help you apply the knowledge.

Structure and Chemistry: What cellulose actually is

Cellulose is a polymer consisting of repeating bD-glucopyranose unit linked by b(1-4). glycosidic bond. The result is:

- The hydrogen-bonded crystal regions are formed when the chains align to form long, extended crystalline regions. This gives fibers their strength and stiffness.

- Amorphous zones between crystalline regions allow access to water and chemicals.

- Manufacturers measure chain by degree polymerization (DP).. Cotton DP can range from 1,000 up to 10,000, depending on the species and processing. Wood pulps, however, usually show 300-1,500, after kraft pulping.

In turn, the chain length, crystallinity and hydrogen bonds together determine mechanical strength and thermal behavior.

Primary sources and how industry extracts cellulose

The industry sources cellulose from a variety of feedstocks. Each source requires a different method of extraction.

| Source | Details of typical feedstock | Extraction approach (key steps) |

|---|---|---|

| Cotton lint | Nearly pure cellulose; long fibers | Ginning, scouring and mercerization are optional. |

| Wood (softwoods/hardwoods) | Lignocellulosic matrix: cellulose + hemicellulose + lignin | Bleaching – Refining |

| Bast fibers (flax and hemp) | Plant stems are bound with fibers by pectin, lignin and pectin | Retting (microbial and chemical) – decortication, scutching and hackling |

| Bagasse, straw and grass | Low cellulose and higher ash | Chemical pulping, bleaching and ash removal |

| Bacterial cellulose | Microbial fermentation (Gluconacetobacter) | Purification by static or agitated culture (alkali wash). |

The manufacturers can also choose the pulping and whitening conditions for dissolving fiber, (high purity and high DP of regenerated fibres), or pulp for paper, (optimized strength and yields).

Read More: Production of Carbon Black. Profitable Opportunities in Carbon Black Business.

Types of cellulose fibers and how factories make them

I describe the production processes and key parameters for each of four classes of fibers.

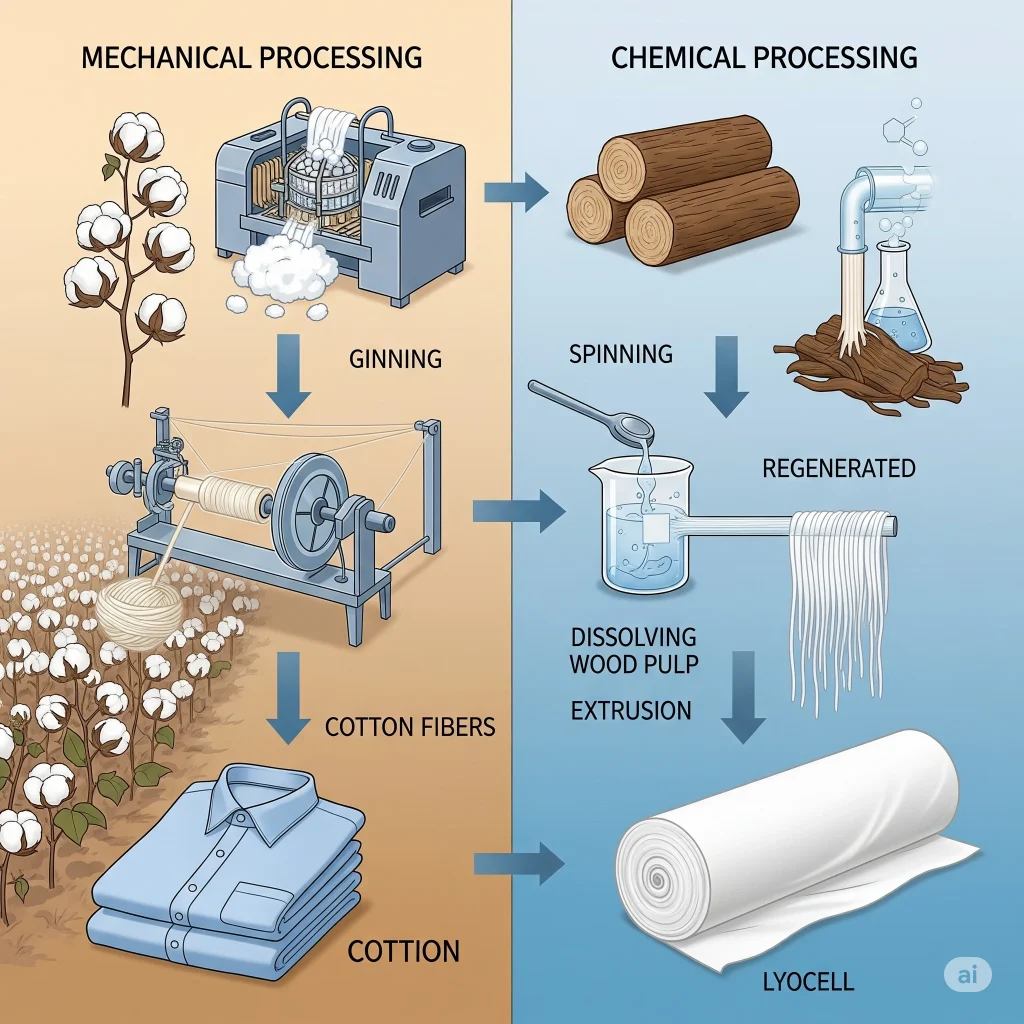

1. Natural plant fibers (cotton, flax, hemp, jute)

- Processing After harvesting mills perform mechanical separation, combing and ginning.

- Control Points: Retting temperature and time control fiber bundles. Over-retting causes fibers to weaken, while under-retting results in impurities.

2. Regenerated cellulose fibers (viscose/rayons, modals, lyocells)

- Rayon: The industry dissolves the pulp in caustic soap, reacts with carbon dioxide to produce cellulose xanthate and then extrudes it into an acid bath. Manufacturers can control aging time and xanthation level, as well as bath composition, to determine DP, tenacity and cross-sectional shape.

- Lyocell solvent (NMMO): The producers dissolve the pulp directly in NmethylmorpholineN-oxide and extrude it through spinnerets. They then wash the solvent to reuse. Lyocell is stronger and has a lower environmental impact than viscose.

- Controls: Pulp DP, solvent recovery rates (>99% for lyocell plants) and spinneret design to achieve desired filament cross section.

3. Nanocellulose (CNC, CNF)

- Cellulose Nanocrystals: Prepared by controlled acid hydrolysis, usually sulfuric acid. This removes amorphous regions and leaves rigid rod-like crystallites. The typical CNC length is between tens and hundreds of nanometers. The width ranges from 3-20 nm.

- Cellulose Nanofibrils: Produced by mechanical fibrillation after chemical or enzyme pretreatments (TEMPO oxidation and carboxymethylation), to reduce energy consumption.

- Process challenges Control surface charge (sulfate group from sulfuric acid), Rheology of concentrated Dispersions and Drying without irreversible Agglomeration.

4. Bacterial cellulose

- Production: Fermentation of selected microbes on sugar media. Bacteria secrete nanofibrillar, cellulose pellicles that are nearly pure.

- Advantages High crystallinity and purity; unique 3D network. Fermentation scales are more expensive than plant pulp routes.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Physical and mechanical properties (with typical ranges)

Here I will list the key properties that designers use when working with cellulose fibers.

| Property | The typical range of notes |

|---|---|

| Density | 1.50-1.60 g/cm3 (cellulosic fibers) |

| Tensile strength of single fiber | 200-1,500 MPa depending on fiber (cotton lower, flax/hemp higher) |

| Young’s modulus | 5-80 GPa (cotton 5-12 GPa; bast fibers 30-70 GPa; CNC modulus 100-150 GPa) |

| Breaking at a break? | 1-15% |

| Moisture regain | 6-12% (depending on humidity; affects dimensional stability). |

| Thermal degradation begins | 240-332degC in an inert atmosphere |

The engineers match the fiber treatment and choice to the mechanical performance and operating temperature.

Surface chemistry, treatments, and compatibilization

The hydroxyl groups in cellulose allow chemists to modify surfaces. Surface treatments can include:

- Mercerization (alkali treatment): Improve dye absorption and interfacial bonds by increasing fiber roughness.

- Silane coupling agent: Use silanes to create covalent bonds between polymer and cellulose matrices. This improves composite strength.

- Acetylation/Esterification: Reduce the hydrophilicity of matrices by substituting OH groups with other ester groups. This improves compatibility and dimensional stability.

- Grafting: Promote interphases covalent when mixing thermoplastics with maleic anhydride and acrylic monomers.

- Corona or plasma treatments: Add polar groups to surfaces or roughen them without chemicals

The manufacturers select the treatment according to the matrix type (thermoplastic or thermoset), durability required, and cost.

Read Our Book: Click Here

Converting cellulose fibers into products: spinning, forming, and composite processing

- Textiles Mills can control spinneret size, composition of coagulation baths and post-stretching for regenerated fibres to adjust tenacity, elongation and strength. In spun yarns, ring or open-end spinning determines yarn uniformity.

- Composites: Manufacturers use continuous yarns/plies or cut fibers into target lengths for short fiber composites. Then, they impregnate the fibers with thermoplastic or thermoset resins (epoxy or polypropylene), and use compression or injection molds to consolidate the parts.

- Films & membranes: Nanocellulose films are formed by casting and drying dense nanocellulose suspensions; the producers then add chemical crosslinking and plasticizers to adjust barrier properties and mechanical properties.

- 3D Forms: The freeze-drying of CNF gels produces aerogels that have a very low density, but a high surface area. These aerogels are ideal for insulation and filtration.

To meet mechanical targets, most industrial lines balance the fiber orientation, volume fraction, and interfacial adhesiveness.

Read More: Start a Profitable Retail Franchise Business in India

Testing and quality control (common analytical methods)

The companies test the cellulose fibers in multiple places:

- Degrees of Polymerization (DP). — Viscometry or size-exclusion methods. DP impacts strength and processingability.

- Index of crystallinity — The X-ray diffractogram (XRD), which gives the crystalline fraction, often increases modulus.

- NMR / FTIR — identify functional groups and confirm chemical modifications.

- TGA/DSC — Determine thermal stability and transitions. Set processing limits.

- SEM/TEM — Examine surface morphology at the micro- and nanoscale.

- Mechanical Tests — Single fiber tensile test, yarn tests and composite flexural/tensile test follow standard testing methods.

- Moisture Sorption Isotherms – Determine dimensional and properties changes with RH.

Labs can ensure product quality and process control by using a series of physical and chemistry tests.

Applications and case uses (concrete examples)

- Textiles and apparel: The Lyocell (Tencel), which is a soft, supple fabric, has a high strength and moisture management when wet. Mills also use post-treatments for wrinkle resistance.

- Interiors for automobiles: Natural fibre mats (flax and hemp) are used to replace glass fibers in trunk liners and door panels. They reduce weight and increase recyclability, when combined with thermoplastic matrixes.

- High performance composites: The CNCs are used to reinforce polymer matrixes with low loads, increasing modulus and barrier characteristics in packaging films.

- Biomedical Products: Bacterial Cellulose is used for tissue scaffolds and wound dressings because of its purity and nanofibrous networks.

- Membranes and filtering: Nanocellulose filters viruses and nanoparticles based on size exclusion, surface charge and membranes.

These examples show how surface chemistry and processing routes determine final performance.

Read Our Project Report: Click Here

Environmental, recycling, and regulatory considerations

- Biodegradability Cellulose degrades with enzymatic or microbial action. However, surface modifications and additives (e.g. heavy crosslinking), can slow down degradation.

- Life cycle impacts: Manufacturers are increasingly quantifying embodied energy in pulping and solvent recovery.

- Recycling Paper, textile, and other recycling streams can recover cellulose. However, with each cycle of reprocessing, DP is reduced and its properties are altered, so manufacturers often mix recycled fibers with virgin pulp.

Designers must therefore balance performance, durability and end-of life when choosing cellulose fibers.

Conclusion

Cellulose fibers are available in a wide range of forms, from the cellulose strands found in plants to nanoscale crystals. Therefore, manufacturers and engineers must control feedstock selection, pulping/fermentation, chemical modification, and fiber treatment to achieve target properties and environmental goals. Understanding the molecular structures, production techniques and surface chemistry in depth will help you choose or design materials that meet mechanical, thermal and sustainability requirements.

Cellulose Fiber: Frequently Asked Questions (brief)

Q – Which cellulose fiber has the highest tensile strength?

A — CNC is the fiber with the highest intrinsic modulus at the nanoscale (100-150 GPa); bast fibers are the plant fibers that tend to have the highest practical modulus for composites.

Q – How does moisturizing impact strength?

A — Water plasticizes amorphous areas and reduces stiffness. Designers must account for property changes of 20-40% in humid conditions.

Q – Are regenerated fibers sustainable?

A — Lyocell has a high sustainability profile if mills use certified pulp and recover >99% of the solvent. Viscose, on the other hand, requires careful solvent management and recovery.