Plastic is one the most innovative materials ever invented. It’s lightweight, durable and versatile. Plastic has revolutionized industries from automotive and packaging to construction and healthcare. Its very durability has caused a global problem: plastic waste which takes hundreds of years to degrade and pollutes the oceans. Biodegradable materials are being used to reduce the environmental impact of plastics.

This shift for entrepreneurs is about more than just solving an urgent environmental problem. It’s about tapping into the rapidly expanding global market. Biodegradable materials are a frontier in which sustainability, innovation and profitability meet. This article examines the landscape of the biodegradable industry, including market opportunities, demand drivers and manufacturing processes. It also discusses challenges for startups looking to enter the space.

Market Outlook: A Rising Wave

Global biodegradables plastics market is expected to grow at a CAGR of 9-10% by 2030. Europe is currently the leader in consumption, due to its strict regulations regarding single-use plastics. However, Asia-Pacific, led by India and China, is quickly catching up.

The ban in India on single-use polymers by 2022 is causing a huge push to find alternatives. Packaging, food service and agriculture are among the industries that are exploring biodegradable alternatives. India is a hotspot of biodegradable plastics startups due to the regulatory change and growing consumer awareness.

Global Biodegradable Plastics Market Forecast

| Year | Market Size (USD Billions) | CAGR (%) | Key growth drivers |

| 2023 | 7.8 | – | Consumer awareness about single-use plastics bans |

| 2025 | 10.3 | 9.5 | Food packaging, ecommerce, agriculture |

| 2030 | 16.0 | 9.8 | Bio-based Polymers: Sustainable Innovation |

Read More: Bioplastics & Biodegradable Products Manufacturing

Demand Drivers

Biodegradable plastics are being adopted for a variety of reasons. Government regulation is the most important factor. Around the world, countries are restricting or banning traditional plastics. This includes single-use products like bags, cutlery and packaging films. These policies have created an already-existing market for biodegradable products.

Another strong force is consumer demand. Consumers are more willing to pay for eco-friendly tableware, compostable bags and sustainable packaging as environmental awareness increases. Adopting biodegradable materials isn’t just about complying with regulations, but also about corporate responsibility and branding.

Demand is also increasing for industry-specific packaging. Food and beverage packaging must be compostable for takeaway and delivery. Biodegradable mulch film is being used in agriculture to enrich soil instead of polluting. Even the automotive industry has begun experimenting with biodegradable interior components that combine sustainability and performance.

Read Our Book: Click Here

Biodegradable Plastics: Key Types

Biodegradable Plastics are broadly classified into bio-based plastics and petrochemical based plastics.

- Bio-based materials are made from renewable resources, such as corn or sugarcane. Examples include polylactic acid (PLA), widely used in packaging and 3D printing, and polyhydroxyalkanoates (PHAs), produced through microbial fermentation.

- Biodegradable plastics derived from fossil fuels, such as polybutylene-adipate-terephthalate or PBAT, are made by synthesizing fossil fuels and engineered to degrade more quickly.

Startups can choose based on the feedstock available, costs, and target market segments. Bio-based plastics are more sustainable but often costlier, while petrochemical-derived biodegradable options may be more scalable in the short term.

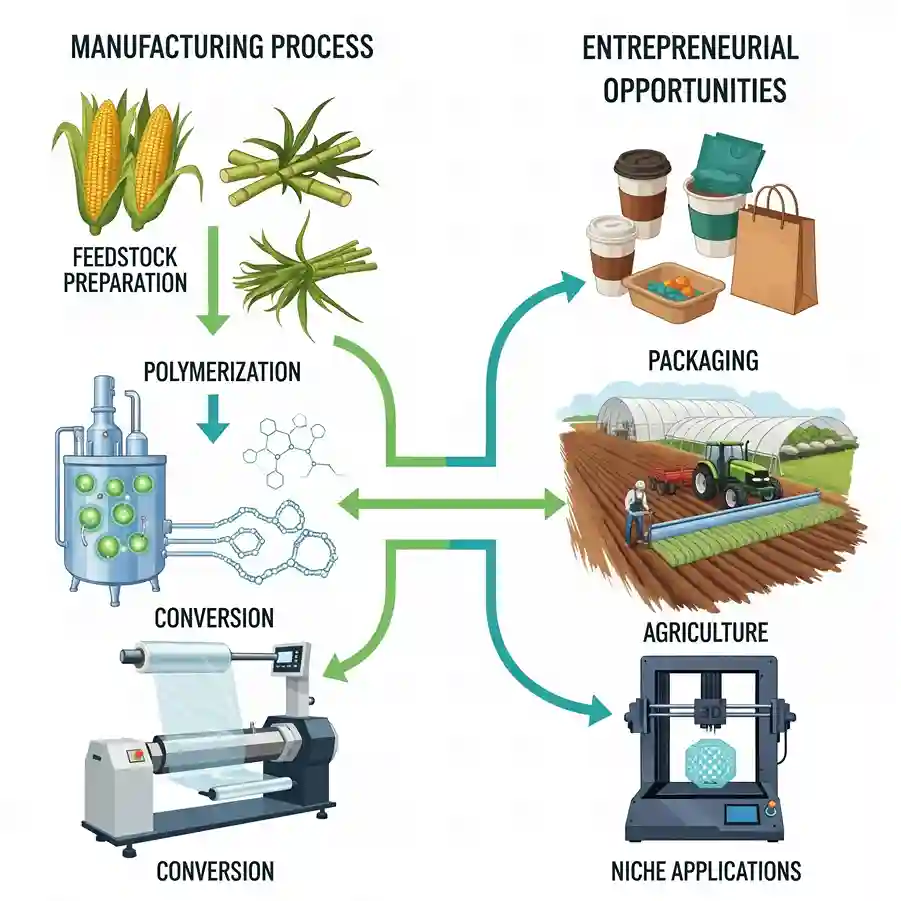

Manufacturing Process Overview

Three stages are involved in the production of biodegradable materials, depending on their type.

- Feedstock preparation – This typically involves agricultural inputs such as corn starch or cane sugar. Sugar feedstocks can be converted to polymers such as PHAs by microbial fermentation.

- Fermentation or Polymerization – For example, PLA is made by fermenting dextrose to lactic acid and then polymerizing it into pellets. PHAs can be produced by feeding microorganisms sugars or oil under certain conditions.

- Process and Conversion: The polymer is converted into sheets, films or molded goods using traditional plastic manufacturing equipment such as extrusion and injection molders.

In manufacturing, the key challenge is to ensure that plastics perform at par with conventional ones. Biodegradable materials must be durable, flexible, transparent, and maintain compostability.

Read More: Starting a Biodegradable Mulching Film Business in India

Opportunities for Entrepreneurs

Biodegradable plastics are a sector with many opportunities. Packaging is the largest and most immediate segment. Demand comes from food delivery, retailers, and ecommerce. Entrepreneurs can set up manufacturing units that produce compostable carrybags, food packaging films and disposable cutlery.

Biodegradable Mulch Films are another option for the agriculture sector. They not only control weeds, but they also conserve moisture in the soil and decompose back into it after use. This eliminates disposal problems.

Startups can also explore niche application such as biodegradable medical implants made of PHAs or compostable hygiene items. Specialty applications in electronics, automotive and other fields are emerging as a result of growing R&D.

Waste management solutions are another promising option. Startups can focus on creating biodegradable materials that work with local recycling or composting systems. This creates a closed loop ecosystem.

Read Our Project Report: Click Here

Challenges and Barriers

Startups must be prepared for huge challenges, despite the enormous opportunity. Biodegradable plastics are currently more expensive to produce than conventional plastics, due to the high cost of feedstocks and complicated processes. One of the biggest challenges is achieving price competitiveness.

Infrastructure is another problem. In many countries including India, there are not enough industrial composting facilities for biodegradable plastics to degrade. Perception issues can arise from confusion about “biodegradable plastics” and “compostable plastics”.

Agricultural fluctuations can affect the availability of raw materials such as corn or sugarcane. To market products as truly biodegradable, entrepreneurs must navigate through strict regulations and certifications.

Biodegradable Plastics: Key Players on the Global Stage

| Name of the Company | Country | Key Products/Focus Areas |

| BASF SE | Germany | Biodegradable plastics based on PBAT, Ecoflex (r) |

| NatureWorks LLC | USA | PLA (IngeoTM) – packaging and 3D printing |

| Novamont S.p.A. | Italy | Mater-Bi (r), biodegradable starch-based resins |

| Mitsubishi Chemical | Japan | PBS – eco-friendly bioplastics |

| TotalEnergies Corbion | Netherlands | PLA joint venture – packaging, food service |

| Danimer Scientific | USA | PHAs for packaging and food containers |

| Green Dot Bioplastics | USA | Compostable resins for consumer goods |

| Biome Bioplastics | UK | Packaging made from bio-based polymers |

| FKuR Kunststoff GmbH | Germany | Bio-flex(r), biodegradable polymer blends |

| Reliance Industries | India | Explore bio-based packaging materials |

Local startups in India, Asia, and Europe are gaining ground by focusing their efforts on niche markets, such as compostable bags and food packaging.

Read More: Environment-Friendly Lucrative Business Idea of Bio-Degradable Plastic Polymer from Corn

India’s Strategic Advantage

India offers a unique opportunity to startups working in the field of biodegradable materials. The country’s large agricultural base provides abundant feedstocks, such as sugarcane and starch, that can be used to produce bio-based plastics. Government policies that ban single-use plastics encourage businesses to find alternatives.

India’s growing E-commerce sector is expected to reach USD200 billion by 2027. This will be a strong driver of demand for sustainable packaging. The government also supports bio-economy and offers incentives to startups involved in green manufacturing. These factors together make India the leading hub for biodegradable ventures.

Conclusion

Innovation, consumer behavior, and regulation are all closely linked to the future of biodegradable materials. As technology scales up, costs are expected to drop. Meanwhile, new materials such as starch and PHA blends will offer better performance. Governments will continue to tighten restrictions on conventional plastics and expand the market for sustainable alternative materials.

Entrepreneurs can achieve success by choosing the right niche, investing heavily in quality and research, and forming partnerships with industries that are eager to adopt eco-friendly solutions. The biodegradable revolution will be led by those who can combine affordability with sustainability.

Discover the Right Business for You With Our Startup Selector Tool

About Niir Project Consultancy Services

Niir Project Consultancy Services helps entrepreneurs explore new opportunities, such as biodegradable materials with confidence. NPCS provides detailed techno-economic feasibility reports that cover manufacturing processes, materials, plant layouts and financial projections. NPCS has decades of experience in helping startups assess the feasibility of setting-up biodegradable units and building sustainable ventures within this fast-growing sector.

Biodegradable Plastics Business: Frequently Asked Questions (FAQs)

Q1: How big is the market for biodegradable plastics?

The market is big—$7.8 billion in 2023. Experts say it will hit $16 billion by 2030. Bans on single-use plastics and demand for green products push this growth.

Q2: Why is demand so high?

Three reasons: Governments ban regular plastics. People want eco-friendly stuff. Big industries need to follow rules and keep customers happy.

Q3: What are biodegradable plastics made from?

They come from two main sources. First, plants like corn, sugarcane, or cassava. Second, oil-based materials made to break down naturally.

Q4: Where are the best startup chances?

Look at packaging, like bags and boxes. Farms need mulch films that decompose. Everyday goods like cutlery and trash bags also sell well.

Q5: What are the big challenges?

Costs are high. Not enough composting plants exist. Raw material prices change a lot. Laws and certifications are strict.

Q6: Why does India stand out?

India grows lots of crops. The government bans single-use plastics. E-commerce and food services need better packaging. Demand is strong.