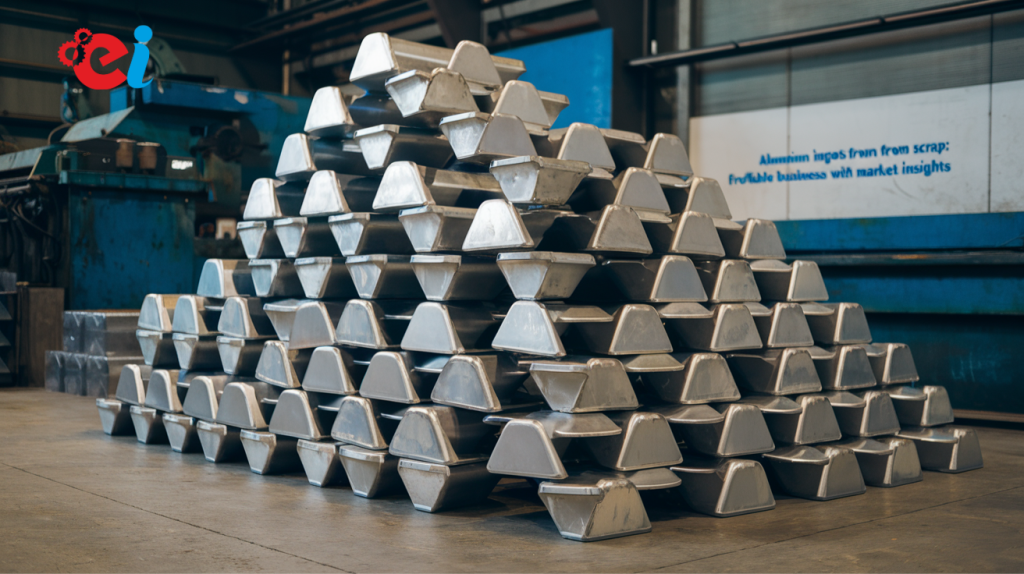

Recent scientific interest in aluminium recycling derives from its simultaneous environmental advantages as well as financial advantages. Starting an aluminium ingots business from scrap materials proves to be financially lucrative. The aluminum industry works toward sustainability and resource efficiency. The market presents entrepreneurs with an opportunity to start their businesses.

Market Overview

The aluminium ingots market demonstrates quick expansion in its sector. Industrial sector growth requirements, along with others, have boosted Aluminium ingot production.

1. Market Size and Growth

The market valuation of aluminium ingots reached USD 269.12 billion during 2024 at a global level. The aluminum ingots market analysts forecast a total value of USD 536.97 billion for 2034. A compound annual growth rate (CAGR) projection shows a value of 7.15%. The market expands because aluminum ingots find applications in multiple sectors, such as automotive aerospace and construction industries.

Visit this Page for More Information: Start a Business in Aluminium Downstream Sector

2. Demand in Key Industries

Various industrial sectors push up the demand for aluminium ingots in the market.

- Automotive Industry

The automobile industry requires aluminium to fabricate lightweight production components. Automobile manufacturers use aluminium because it helps to enhance vehicle fuel economy levels. Aluminium ingots fulfil the rising manufacturing requirements of car production industries.

- Construction Industry

The construction industry implements aluminium on a broad scale for its building materials. The metal exhibits durability and corrosion resistance and weighs light compared to other materials. Aluminium ingot demand has risen parallel to present-day urbanisation trends.

- Aerospace and Defense

The aerospace industry, together with the defence industry, utilises aluminium extensively. Manufacturers who build aircraft need lightweight yet durable substances. Aluminium ingots deliver an effective solution when it comes to this requirement.

3. Regional Market Insights

Aluminium ingots experience differing levels of market demand throughout different parts of the world.

- Asia-Pacific

Aluminium recycling occupies the top position within the Asia-Pacific industrial sector. China and India experience growing aluminium requirements because of their speeding industrial and urban development. The location drives major production amounts for aluminium worldwide.

- North America

The production of aluminium items in North America emphasises sustainability standards. The increasing market receives support from cutting-edge recycling innovations. The present market has motivated companies to build efficient aluminium processing operations.

- Europe

Europe enforces strict environmental policies. Multiple industrial businesses work to minimise their carbon footprint. Using aluminium ingots supports the accomplishment of sustainability objectives.

Related Business Plan: Aluminium Ingots From Aluminium Scrap

Aluminium Scrap Recycling Process

Scrap aluminium evolves through multiple important procedures to generate aluminium ingots.

- Collection and Sorting

The collection of aluminium scrap comes from multiple different origins. A sorting process determines the separation of pure aluminium from different materials contained in the mix. The process leads to producing an outstanding end result.

- Cleaning

The cleaned scrap material receives additional processing before it is ready for further steps. The elimination of paint, oil, and dirt takes place during this phase. The efficiency of melting production increases due to this step.

- Melting

The high-temperature furnace serves to melt cleaned aluminium scrap. Step one of the process entails refining the melted aluminium to enhance purity and improve quality. Standardisation processes take effect during the production of ingots.

- Casting

Production operators fill the melted aluminium into moulds, which creates ingots as the product. The solidified ingots receive extraction from their molds after the cooling process. After the completion of processing, these items become ready for commercial distribution.

moulds

When aluminium scrap goes through the recycling process to become ingots, it delivers various benefitting points.

- Energy Efficiency

The production of recycled aluminium from its scrap form needs only 5% of the energy which primary aluminium requires. The energy-efficient operation system lowers both operational expense and expenditures. The profitability of aluminium recycling becomes possible because of its energy-efficient nature.

- Environmental Sustainability

The recycling process decreases the requirement for extracting fresh aluminium from mines. This production method decreases environmental carbon pollution substantially. The practice of recycling aluminium enables progress toward sustainability goals at an international scale.

- Cost-Effectiveness

The manufacturing process of aluminium becomes more affordable through the extraction of aluminium scrap materials. Lower material expenditure benefits the business sector. Steady profits exist because of the constant demand for aluminium ingots.

Challenges in Aluminium Scrap Recycling

The practice of aluminium scrap recycling encounters multiple obstacles even though it demonstrates numerous advantages.

- Quality Control

Purifying recycled aluminium presents significant obstacles to industry professionals. Scrap material varies in composition. Accomplishing quality assessment necessitates using advanced techniques for material refinement.

- Market Volatility

The worldwide economic climate causes aluminium materials to experience price fluctuations. Trade regulations, together with tariffs, create disturbances for the stability of industries. Businesses need to modify their operations based on shifting market fluctuations.

- Technological Investment

Establishing new aluminium recycling facilities demands big financial investments from business operators. The implementation of present-day technology equipment helps organizations achieve better operational efficiency. Staying competitive requires continuous innovation.

Investment Opportunities

Aluminium recycling produces multiple business possibilities that entrepreneurs can take advantage of.

- Recycling Plant Establishment

Starting an aluminium recycling facility will provide enduring advantages for business operations. The continuous market demand for aluminium ingots delivers steady financial income to companies. Advanced recycling techniques enhance profitability.

- Technology Development

The development of research and development efforts boosts the efficiency of recycling operations. Modern innovations create more efficient processes that lower costs simultaneously. Better technology provides businesses with stronger competitive standings.

- Government Support

Public authorities support aluminium recycling through established policies. Business entrepreneurs receive financial motivators that push them toward investing in the industry. Government subsidies, together with grants, enable startups in the recycling industry.

Related Feasibility Study Reports: Aluminium Ingots From Aluminium Scrap

Future Outlook

The market for the aluminium recycling sector demonstrates an ongoing expansion path. Technological advancement along with sustainable practices leads to industry growth. Enterprises should consider metal ingots since their market value appears to grow in the future. Major financial gain exists for companies that invest in this industry sector.