The chemical industry is a crucial part of the current worldwide economy. Its goods are present in nearly all areas of our daily lives, from cleaning items to food packaging and more. This makes starting a business in this sector very profitable. Here, we will go through eight business ideas within the chemical industry that have great potential for startups.

8 Profitable Chemical Industry Business Ideas

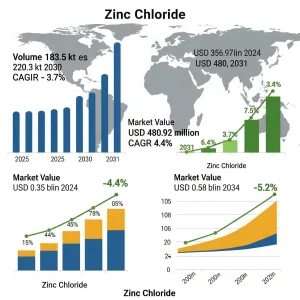

1. Zinc Chloride Production Market

The worldwide market for zinc chloride is growing rapidly. Zinc chloride has numerous uses, such as in metal treatment, textile processing and as a catalyst in organic synthesis. This market is projected to expand significantly due to the increasing requirements from these areas.

Reason for Investing: There continues to be strong demand for zinc chloride in the market, especially in developing countries where industrial activities are growing rapidly. Flux for metal soldering and battery electrolytes are the two main uses of potassium carbonate, ensuring its steady importance and place in the marketplace.

Related article: The Most Profitable Chemical Industry Business in the Philippines

2. The Market for Polyacrylamide Production

Polyacrylamide, a key component in water treatment, is used for making paper and acts as a flocculant to assist with various industrial processes. Stringent environmental regulations and the need for efficient methods of treating water are expected to drive the growth of this substance’s market.

Reason for Investment: The increasing significance of clean water and sustainable techniques in areas like mining and food processing has heightened the demand for good treatment chemicals. Polyacrylamide is therefore a strategic investment.

3. Chlorinated Polyvinyl Chloride (CPVC) Production Market Outlook

CPVC is a type of plastic that has many uses, especially in making pipes for hot and cold water, fire sprinklers, as well as handling liquids in industries. The market for this material grows because of the increase in construction works and demand for strong pipes that can resist corrosion.

Reason to Invest: As urbanization and industrialization continue in developing countries, the demand for CPVC is rising. Investing in CPVC production is an attractive opportunity because it has better properties than other thermoplastics.

4. Titanium Dioxide from Rutile ilmenite Ore Market Overview

Titanium dioxide, which is a fine white pigment, is the most common component in paints, coatings, plastics and sunscreens. The market for titanium dioxide grows as industrial sectors like construction and automobiles expand (Owusu et al., 2020).

Reason to Invest: Titanium dioxide is essential for adding color and opacity to various consumer goods, and its demand is also boosted by its ability to resist UV rays in sunscreens.

Related projects on: Chemicals (Organic, Inorganic, Industrial) Projects

5. Soda Ash Production by Solvay Process Market Overview:

Soda ash is a crucial ingredient in various sectors like glass making, detergents and chemicals. The Solvay process, not requiring limestone as input, provides a production technique that is kind to our environment.

Reason to Invest: The Solvay process can provide a solution for the demand of soda ash without substantial carbon emissions, making it suitable for the green economy and conducive to controlling environmental impact.

6. Sodium Silicate from Quartz and Soda Ash Market Overview

Sodium silicate is a versatile compound used in various industries, such as automotive, construction, detergent manufacturing and more.

Reason for Investment: The ability of silica gel to be used in various applications that require protection from moisture ensures a consistent demand for the product. Additionally, the production process is straightforward and can be carried out using raw materials readily available such as sodium silicate.

7. Sodium Chlorite Production by Direct Electrolysis Market Overview

Sodium chlorite is mainly used for making disinfectants and bleaching substances. The market is growing because of increasing hygiene rules worldwide.

Reason for Investment: Using direct electrolysis makes the creation of sodium chlorite cheaper and kinder to the environment. This method matches worldwide movements towards safer and greener chemical processes.

8. Zeolite 4A (Detergent Grade) Production Market Overview

The use of Zeolite 4A is important in detergents because it helps to soften water. As the need for detergents without phosphates grows, the market for Zeolite 4A will also increase.

Reason for Investment: The strong market demand for phosphate-free detergents, as a result of environmental regulations, provides an excellent opportunity to invest in Zeolite 4A production. This investment is also in line with worldwide environmental movements.

Detailed Exploration of Profitable Chemical Industry Business Ideas

Zinc Chloride Production Market Trends and Analysis:

- The market for zinc chloride is boosted by its use in many different industries. It plays a crucial part in making batteries, and as the need for energy storage solutions increases – such as those used with renewable energy systems – this can impact positively on demand levels too.

- Why Startups Should Invest: Zinc Chloride Market The zinc chloride market provides an opportunity for startups to take advantage of both its established uses in various industrial sectors and the potential new applications related to energy storage. Return on investment is moderate, but it can be earned quickly due to the high utility across sectors with a low initial cost.

Polyacrylamide Manufacturing Market Size and Share:

- Polyacrylamide manufacturing, due to its high demand in industries and municipalities across the world, is seen as an attractive investment option. With increasing emphasis on wastewater treatment for environmental compliance in such sectors, the need for this compound continues to grow significantly. The ability of polyacrylamide to effectively assist in water purification makes it a crucial component.

- Why Startups Should Invest: Investing in the production of polyacrylamide could put startups at a leading position within the water treatment industry. The continuous worldwide demand for cleaner water provides the possibility to gain a significant market portion and profit.

Chlorinated Polyvinyl Chloride (CPVC) Production Market Trends and Analysis:

- There is a rising market for CPVC, especially in areas that are seeing quick infrastructure growth. CPVC’s ability to withstand high temperatures and various chemicals makes it suitable for both home and industrial plumbing systems.

- Why Startups Should Invest: CPVC production represents a considerable opportunity because of the constant construction growth happening all over the globe. A startup in this industry could become a big player by providing materials that are high in demand for modern plumbing solutions.

Related Article: What Is The Potential For Chemical Industries In India

Titanium Dioxide from Rutile Ilmenite Ore Market Size and Share:

- The paint and coatings industry, which is a big part of the market, relies on titanium dioxide. It’s also essential for making plastics and paper. Its use as a pigment in many items confirms that it’s safe for human consumption or contact. These characteristics make titanium dioxide highly desirable in consumer goods such as toothpaste and cosmetics.

- Reasons for Startups to Invest: The broad range of uses for titanium dioxide ensures a strong market position. Startups can take advantage of continual advancements in production technology that may lower expenses and increase profit potential.

Soda Ash Production by Solvay Process Market Trends and Analysis:

- The worldwide demand for cleaner production methods gives extra appeal to the Solvay process. Soda ash, which is a key product from this method, continues to have high requirements in making glass and chemicals so there is a consistent market available.

- Why Startups Should Invest: The environmental advantages from Solvay process without limestone might offer notable competitive benefits to startups, particularly in areas with strict environment rules.

Feasibility reports on: Soda Ash

Size and share of market for silica gel crystals & beads from sodium silicate and sulphuric acid

- The market for silica gel is strong and expanding due to the increasing requirement for protecting goods from moisture in shipping and storage, along with a growing global trade and e-commerce sector.

- Why Startups Should Invest: Producing silica gel is a business idea that can be expanded. It needs small starting expenses and has good profit margins, especially because there is an increasing requirement for it in packaging and pharmaceuticals.

Sodium Chlorite Production via Direct Electrolysis Market Trends and Analysis

- Sodium chlorite is needed mainly for its role in water disinfection and sanitation. Its capability to eliminate many types of microorganisms makes it crucial for maintaining public health.

- Why Startups Should Put Money In: Small businesses that adopt the direct electrolysis process will be able to provide a low-cost and friendly to environment product. This can meet the worldwide demand for good disinfectants, especially when dealing with public health issues.

Zeolite 4A (Detergent Grade) Production Market Size and Share

The need for phosphate-free detergents utilizing Zeolite 4A is growing because people are more inclined towards environmentally friendly products. This demand aligns with strict international rules about the environment.

- Advantages of Producing Zeolite 4A: Startups can find themselves at the heart of a developing trend for green consumer products. The move from phosphates in detergents creates an obvious route to gaining market space within the eco-friendly products market.

- For the entrepreneurs who are thinking of putting money into the chemical industry, these eight business ideas not just offer big profits but also match well with worldwide movements towards sustainability and invention. If a startup does careful market study along with clever planning. It can enter these chemical markets and make long-lasting achievements.

For more information, watch the related video on this topic

Key Takeaways

-

Broad End‑Use Demand: Each chemical serves multiple industries, reducing market risk.

-

Sustainability Focus: Processes like Solvay and direct electrolysis align with green regulations.

-

Low‑to‑Moderate Capex: Many of these ventures can start with manageable initial investments.

-

High Growth Potential: Urbanization, water treatment, and eco‑friendly products drive market expansion.

-

Innovation Edge: Startups can leverage newer, cleaner production methods for competitive advantage.

-

Diversification: Offering several value‑added grades or services (e.g., technical support, tailored formulations) enhances margins.

-

Regulatory Alignment: Compliance with tightening global standards is a built‑in selling point.

-

Global vs. Local: While demand is global, local production close to end‑users cuts logistics costs and import reliance.

What business to start ? How to choose a business idea ?

Frequently Asked Questions

Q1. What factors determine the profitability of a chemical manufacturing startup?

A: Key factors include raw‐material costs and availability, energy expenses, economies of scale, process efficiency, product purity requirements, proximity to end markets, and the ability to meet environmental and safety regulations.

Q2. How much initial investment is typically required to launch these chemical businesses?

A: It varies widely. Small‐scale operations (e.g., silica gel, Zeolite 4A) may start with ₹1–3 crore, while more capital‐intensive projects (e.g., titanium dioxide or CPVC plants) could require ₹10 crore or more, depending on capacity and technology.

Q3. What are the main environmental regulations affecting these processes?

A: Regulations cover air emissions (SO₂, NOₓ, VOCs), effluent discharge standards, solid‐waste disposal, and chemical safety (handling, storage, transport). Adoption of cleaner processes (Solvay, electrolysis) helps meet these requirements.

Q4. How can a startup differentiate itself in a mature chemical market?

A: Through product innovation (higher grade/purity), tailored technical support, shorter delivery times, green manufacturing credentials, and value‑added services such as custom formulations or feasibility studies.

Q5. Are there government incentives for green chemical manufacturing in India?

A: Yes—under schemes like the Production Linked Incentive (PLI) for specialty chemicals, state‐level subsidies for pollution control equipment, and tax breaks for setting up in designated industrial zones or SEZs focused on sustainability.